Description

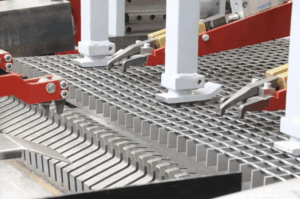

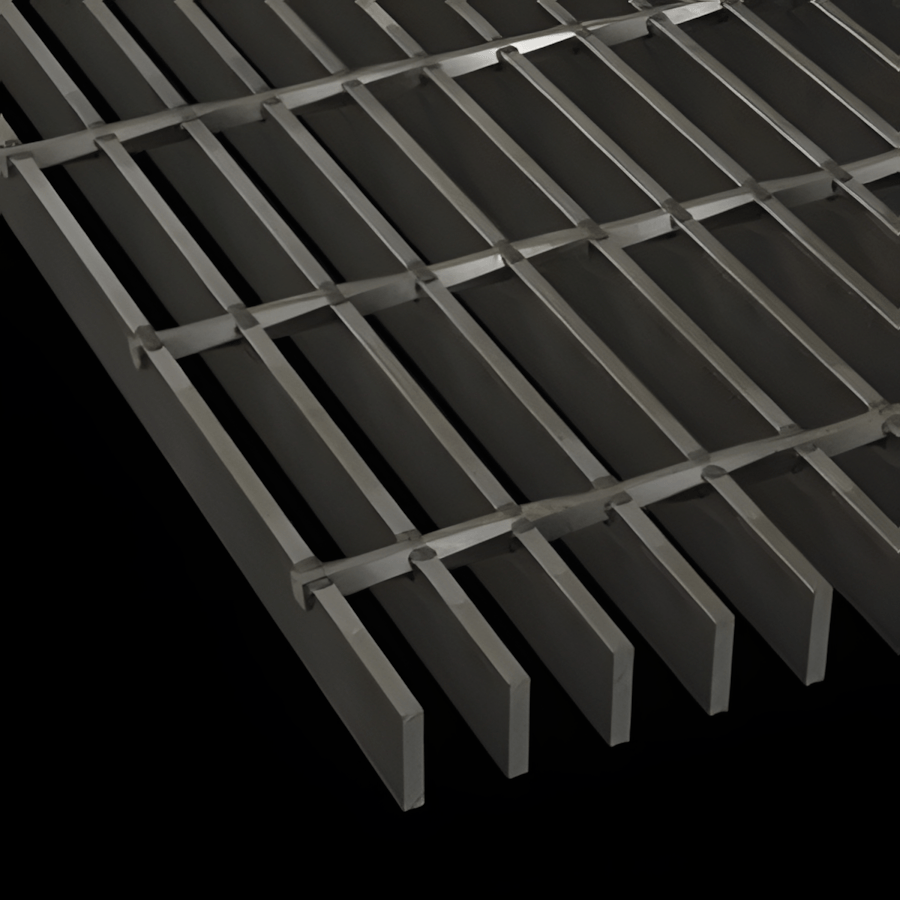

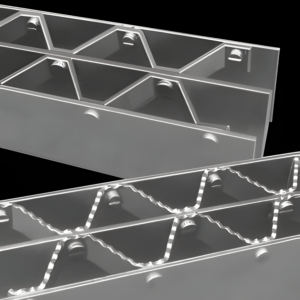

Welded Steel Grating is a rigid, open grid made by welding steel bars (bearing bars and cross bars) at right angles to form a strong, one-piece panel. It is a popular and versatile material used for flooring, walkways, platforms, and drainage covers due to its high strength, durability, and corrosion resistance when coated.

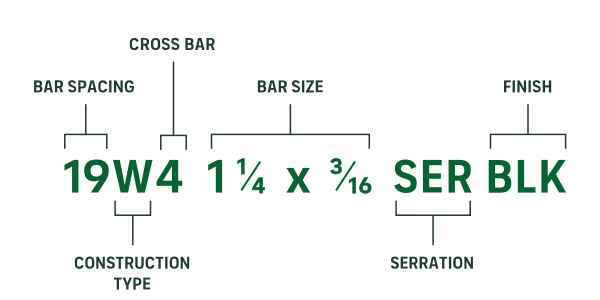

Welded Steel Grating Nomenclature

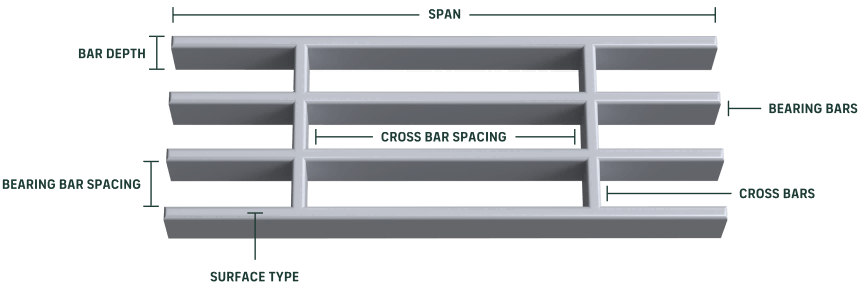

- Bearing Bars – Load carrying, span of grating

- Cross Bars – Connecting bars, runs along width of grating

- Finish – Coating applied-painted black, galvanized

- Serrated – Notching process for non-slip surface

- Widths – Overall dimension measured perpendicular to bearing bars

- Span – Distance running along direction of bearing bars

- Banding – Bar of the same size as bearing bar used to close open ends

- Kick Plate – Flat bar welded to outer edge with projection above grating

Specifications

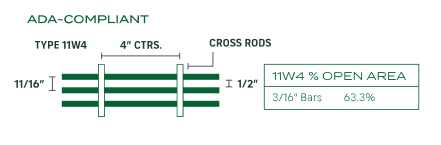

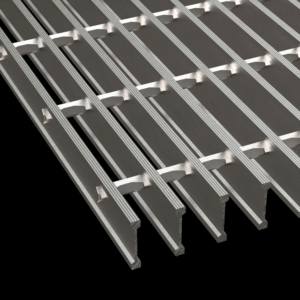

Standard-Duty Welded Steel Grating

Materials: Carbon Steel / Galvanized Steel / Stainless Steel / Aluminium

Surface: Smooth / Serrated

Bearing bar size: 1″, 1-1/4″, 1-1/2″, 1-3/4″, 2″, 2-1/4″, 2-1/2″.

Bearing bar thickness: 1/8″ , 3/16″

Cross bar size: 1/4″, 5/16″ and 3/8″ Square Twisted Rod

Cross bar spacing: 2″ and 4″.

Bar spacing: 11/16″, 15/16″, 1-3/16″

|

|

|

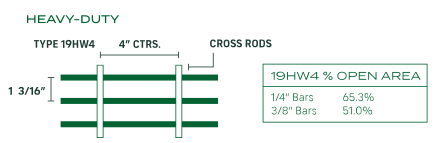

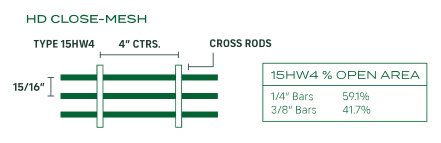

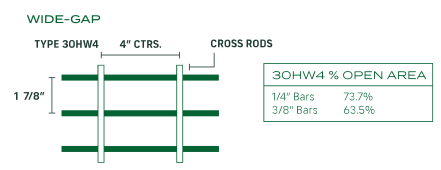

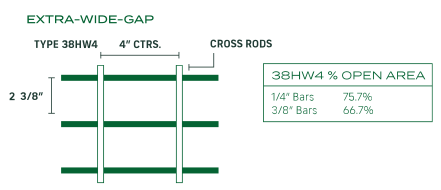

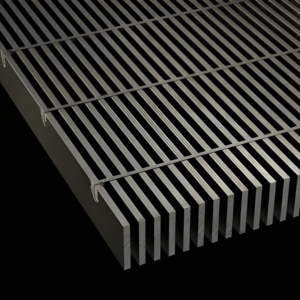

Heavy-Duty Welded Steel Grating

Materials: Carbon Steel / Galvanized Steel / Stainless Steel

Surface: Smooth / Serrated

Bearing bar size: 1″, 1-1/4″, 1-1/2″, 1-3/4″, 2″, 2-1/4″, 2-1/2″, 3″, 3-1/2″, 4″, 4-1/2″, 5″, 5-1/2″, 6″.

Bearing bar thickness: 1/4″, 5/16″ and 3/8″.

Cross bar size: 1/4″, 5/16″ and 3/8″ Square Twisted Rod.

Cross bar spacing: 2″ and 4″.

Bar spacing: 15/16″, 1-3/16″, 1-7/8″ and 2-3/8″.

|

|

|

|

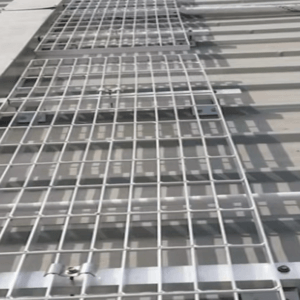

Applications Of Welded Steel Grating

Welded Steel Grating serves countless industrial applications. It provides strong support for heavy equipment. This product allows light and air to pass through. Workers safely walk on these durable panels. Factories install them as operating platforms. They work perfectly in power plants. Wastewater treatment plants use them widely.

Industrial Platforms & Walkways

Standard-Duty Welded Bar Grating creates sturdy work platforms. It supports heavy machinery and tanks. Maintenance crews access equipment easily. These grates serve as safe stair treads. Their anti-slip surface prevents accidents. They form secure walkways between equipment. Oil refineries rely on their strength.

Architectural & Municipal Engineering

Cities choose Heavy-Duty Welded Bar Grating for infrastructure. It makes beautiful commercial building ceilings. Shopping malls use it for ventilation layers. Municipal projects specify it for trench covers. These grates protect tree roots in cities. Pedestrian bridges use them as decking. They reduce structure weight effectively.

Energy & Environmental Protection

Power plants need durable Welded Steel Grating. It forms boiler platforms and walkways. Nuclear facilities use it for maintenance access. Wastewater plants install it everywhere. These grates resist chemical corrosion perfectly. They serve in flue gas purification systems.

Transportation Applications

Ships use Welded Steel Grating as decks. It provides slip-resistant surfaces offshore. Marine platforms choose it for walkways. Some highways install it as guardrails. Ports utilize it for corrosion-resistant platforms. The material withstands seawater environments.

Specialized Applications

Agriculture uses Welded Steel Grating for floors. It creates ventilation in food processing plants. Warehouses install it for mezzanine flooring. Some construction projects need it for scaffolding. Certain industries use it for material screening.

Material Selection For Different Scenarios

- Carbon steel grating suits most industrial applications. Hot-dip galvanizing provides corrosion resistance.

- Stainless steel (304/316) handles extreme environments like coastal areas and chemical plants.

- Aluminum grating offers a lightweight solution for marine and architectural projects.

Each material delivers specific advantages for different operational conditions and longevity requirements.

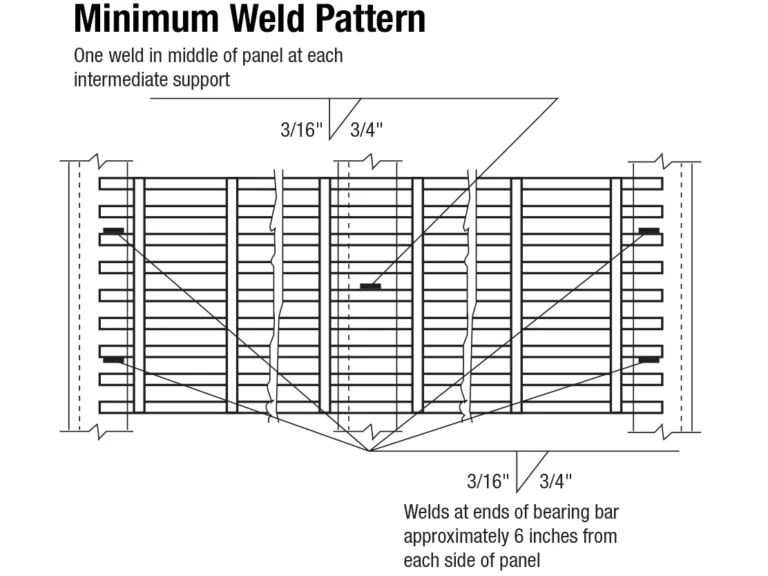

Steel Bar Grating Welding & Fastening Clips

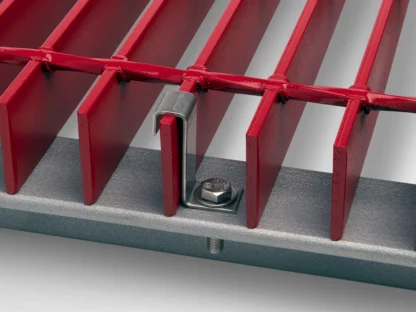

| Welding creates superior permanent installations, while mechanical fasteners (also known as grating clips) provide solutions when grating must be removable or welding is impractical. The recommended weld pattern (illustrated to the right) indicates minimum fastener spacing for pedestrian applications. Vehicular applications typically require additional welding, with specific size and spacing requirements determined by the project’s specifying authority. |  |

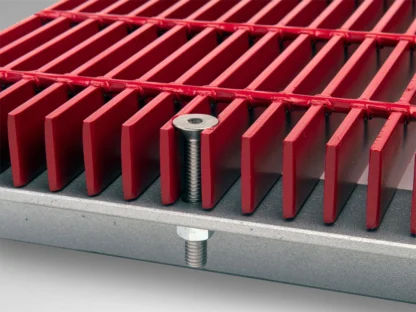

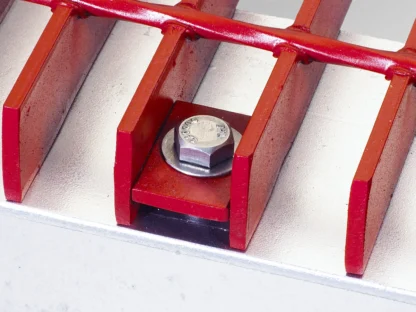

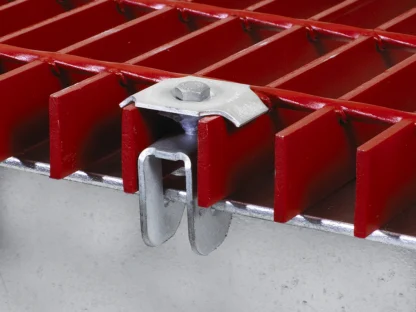

These bent clips, which bridge two bearing bars, are available in galvanized steel, stainless steel, or aluminum. They feature standard 5/16″ bolt holes. Bolts, screws, or other connecting hardware are not included and must be supplied separately. |  The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to accommodate bolt shoulders. Flat head screws or self-drilling fasteners are not included and must be supplied separately. |  Workers weld these pre-punched plates between the bearing bars to facilitate bolting to the supporting structure. Clients must supply bolts, screws, or other connecting hardware separately. |

Installed from the top surface of the grating, these mechanical fasteners create a friction connection with the supporting flange. “G” clips are easily installed without the need for drilling or welding. |  This formed clip captures two bearing bars spaced at 11/16″ on center. Clients must supply flat countersunk screws and other required fastening hardware separately. |  A narrow formed clip used to capture a single bearing bar in applications with limited spacing, typically 11/16″ on center. Cap screws and other necessary fastening hardware are not included and must be supplied separately. |

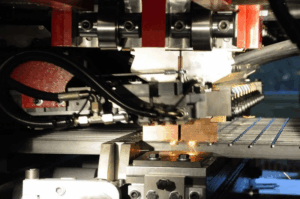

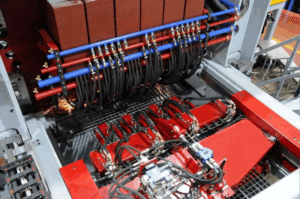

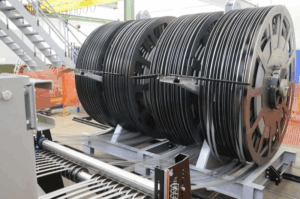

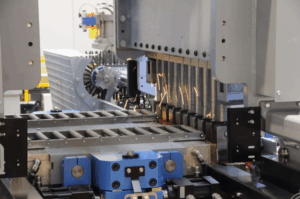

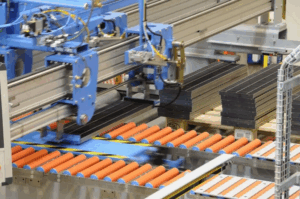

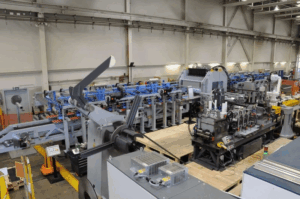

Welded Steel Grating Processing Equipment

Reviews

There are no reviews yet.