Description

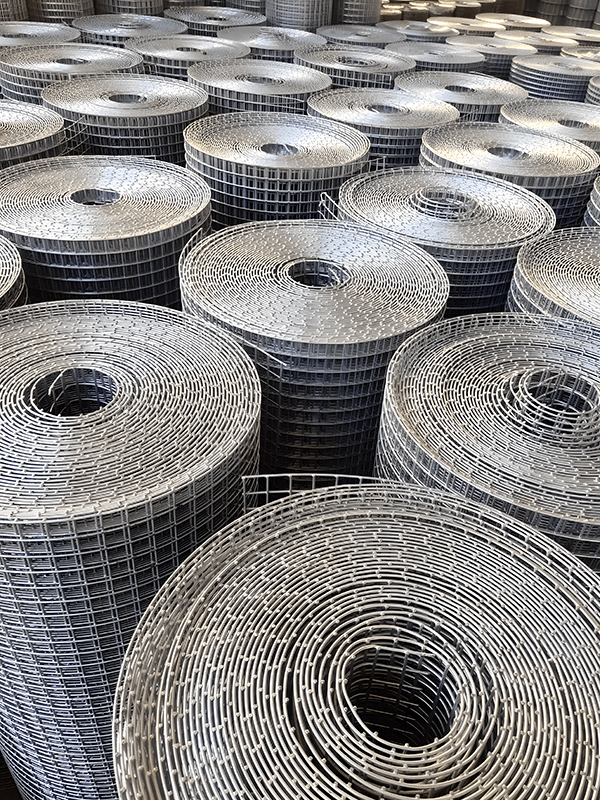

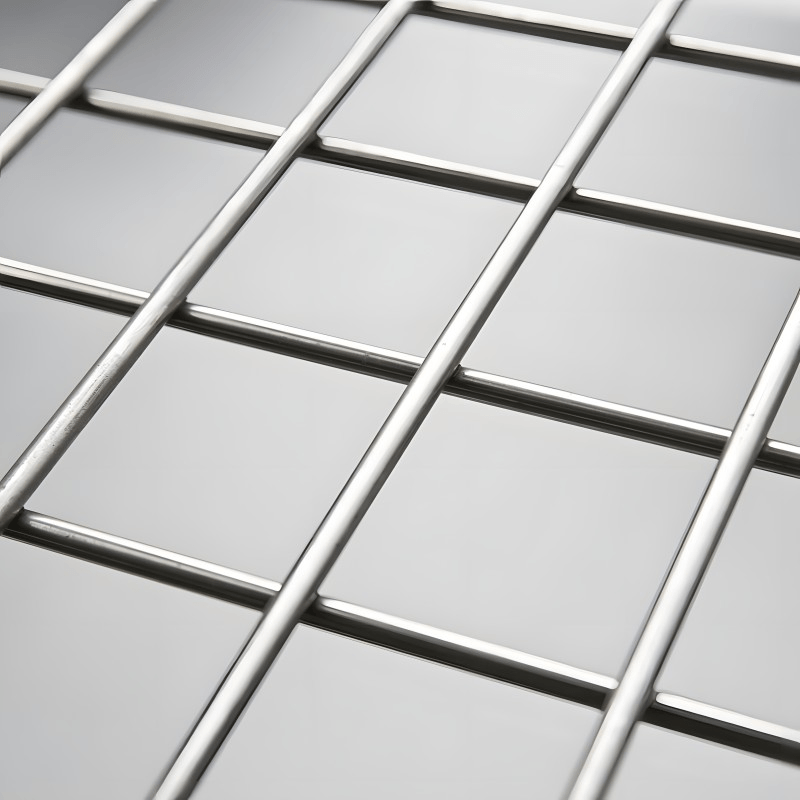

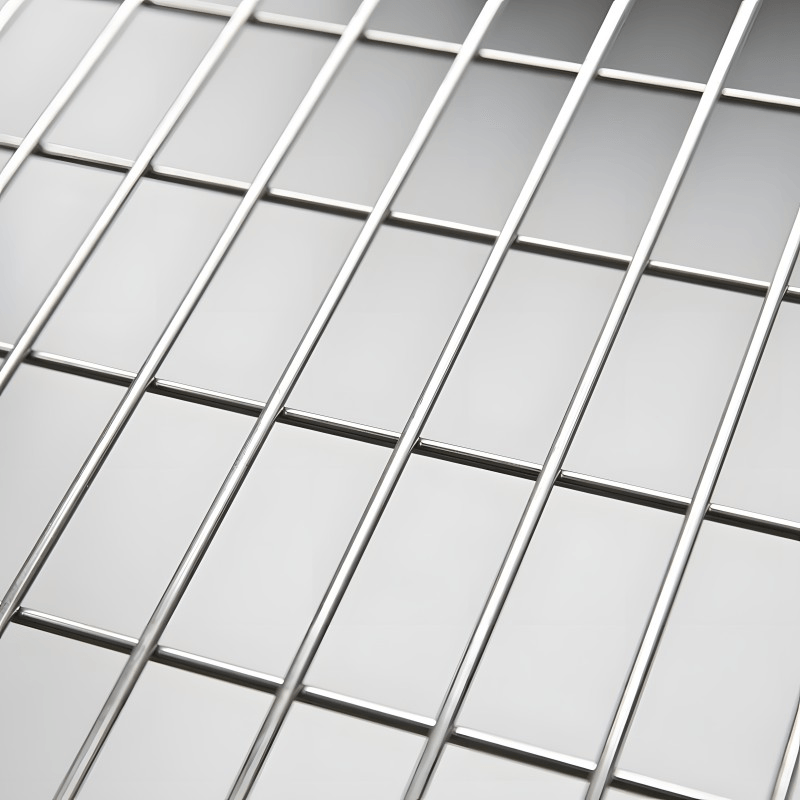

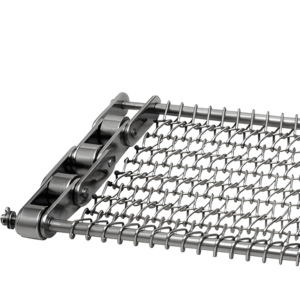

Welded wire mesh, also known as welded wire fabric or welded mesh, uses electrical welding to join longitudinal and transverse wires at their intersections. This process creates strong bonds between the wires. These bonds provide a rigid and stable mesh structure. Manufacturers typically use mild steel, stainless steel, or other corrosion-resistant materials to produce the wires. The wires themselves can take various forms, including bars, round wires, and rectangle strips.

Specifications

| Open(inch) | Open(mm) | Wire Diameter(BWG) |

|

| 1/4″×1/4″ | 6.4mm×6.4mm | 22 / 23 / 24 | |

| 3/8″×3/8″ | 10.6mm×10.6mm | 19 / 20 / 21 / 22 | |

| 1/2″×1/2″ | 12.7mm×12.7mm | 16 / 17 / 18 / 19 / 20 / 21 / 22 / 23 | |

| 5/8″×5/8″ | 16mm×16mm | 18 / 19 / 20 / 21 | |

| 3/4″×3/4″ | 19.1mm×19.1mm | 16 / 17 / 18 / 19 / 20 / 21 | |

| 1″×1/2″ | 25.4mm×12.7mm | 16 / 17 / 18 / 19 / 20 / 21 | |

| 1-1/2″×1-1/2″ | 38mm×38mm | 14 / 15 / 16 / 17 / 18 / 19 | |

| 1″×2″ | 25.4mm×50.8mm | 14 / 15 / 16 | |

| 2″×2″ | 50.8mm×50.8mm | 12 / 13 / 14 / 15 |

Common Wire Gauge and Diameter Comparison Table

Download Complete Common Wire Gauge and Diameter Comparison Table (AWG, BWG, SWG)

| Specification | BWG (Birmingham) | |

| Gauge Number | Inch | mm | |

| 8 | 0.165 | 4.191 | |

| 9 | 0.148 | 3.759 | |

| 10 | 0.134 | 3.404 | |

| 11 | 0.12 | 3.048 | |

| 12 | 0.109 | 2.769 | |

| 13 | 0.095 | 2.413 | |

| 14 | 0.083 | 2.108 | |

| 15 | 0.072 | 1.829 | |

| 16 | 0.065 | 1.651 |

| 17 | 0.058 | 1.473 | |

| 18 | 0.049 | 1.245 | |

| 19 | 0.042 | 1.067 | |

| 20 | 0.035 | 0.839 | |

| 21 | 0.032 | 0.831 | |

| 22 | 0.028 | 0.711 | |

| 23 | 0.025 | 0.635 | |

| 24 | 0.022 | 0.559 | |

| 25 | 0.02 | 0.508 | |

Materials of Welded Wire Mesh

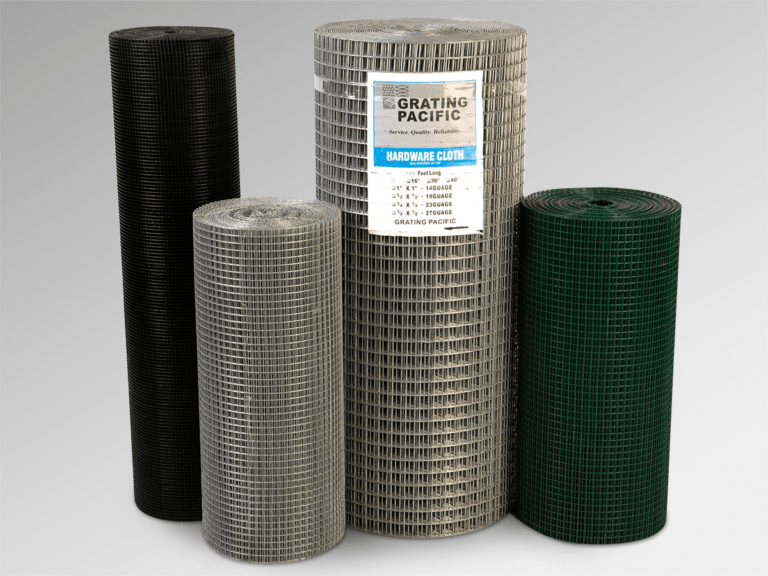

We manufacture welded wire mesh from high-quality low-carbon steel wire and stainless steel. Our production process offers both pre-weld and post-weld galvanizing options. Choose from hot-dip galvanized, electro-galvanized, PVC-coated, or stainless steel varieties.

Galvanized Welded Wire Mesh

We process premium steel wire through precision automated machinery. This creates perfectly flat mesh surfaces with exceptional structural integrity. The welded joints remain secure even after cutting or under pressure. Our hot-dip galvanizing provides superior corrosion resistance. This offers unique advantages over ordinary wire mesh.

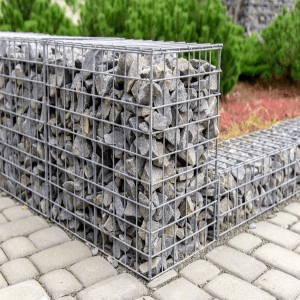

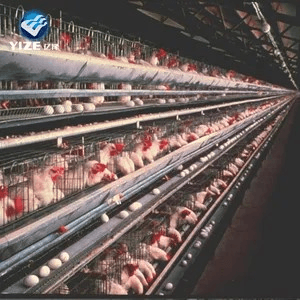

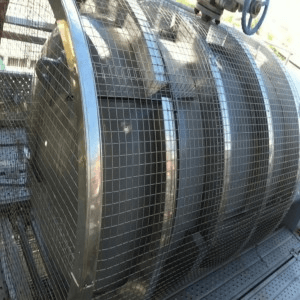

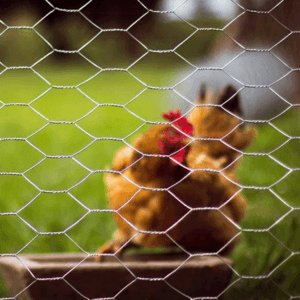

Common Applications: Chicken Cages, Wire Fence, Porch guards and rat prevention screens, Machinery protection covers, Animal and plant enclosures, Industrial, agricultural, and construction uses.

Stainless Steel Welded Wire Mesh

We weld 201, 202, 301, 302, 304, 304L, 316, and 316L stainless steels using precision equipment. The resulting mesh features flawless surfaces and firm connection points. This type offers the strongest corrosion and oxidation resistance. Its price is more expensive than galvanized and PVC-coated alternatives.

Common Applications: Construction concrete reinforcement, Animal enclosures and zoo fencing, Highway guardrails and machinery protection, Sports field perimeter security, Bridge and road construction reinforcement.

PVC-Coated Welded Wire Mesh

We weld premium low-carbon steel wire first, then apply PVC, PE, or PP coatings through high-temperature automated production lines.

Common Applications: Highway and railway fencing, Park and mountain enclosures, Orchard and land demarcation, Agricultural breeding fences, Pet enclosures and animal cages.

How to Order/Custom Welded Wire Mesh

- MATERIAL – Indicate material such as plain carbon steel, stainless steel or other alloy.

- WIRE DIAMETER OR GAUGE – In decimal, thousands of one inch, or gauge.

- WIRE SPACING – Specify square, rectangular or specialty configuration. Wire spacing center-to-center, clear opening, or mesh count.

- SIZES – Indicate sheet or roll width and length, or width and length of cut-to-size pieces.

Reviews

There are no reviews yet.