Description

Swage-Locked Grating

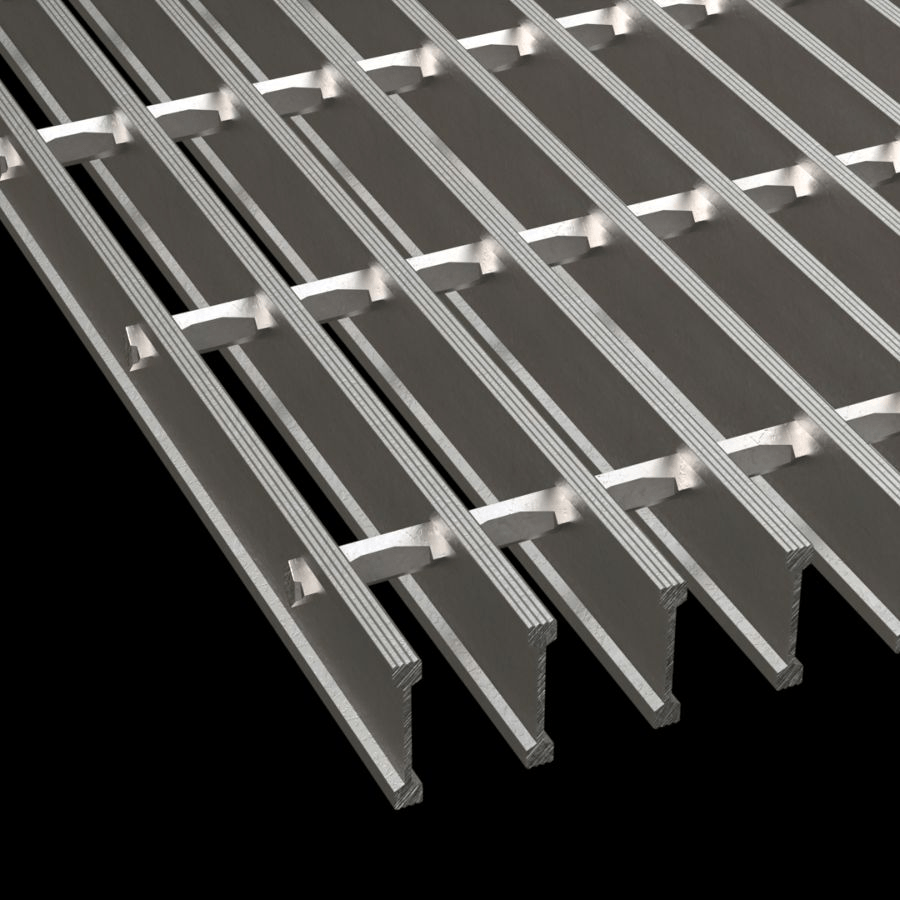

The Swage-Locked Grating manufacturing process utilizes swaging and forming to permanently secure crossbars within the diamond-shaped openings of bearing bars. This method effectively prevents rotation or movement of the components. The resulting product demonstrates an outstanding strength-to-weight ratio while maintaining minimal deflection under heavy loads. These characteristics ensure superior safety for pedestrian traffic in demanding environments like high-rise buildings and offshore platforms.

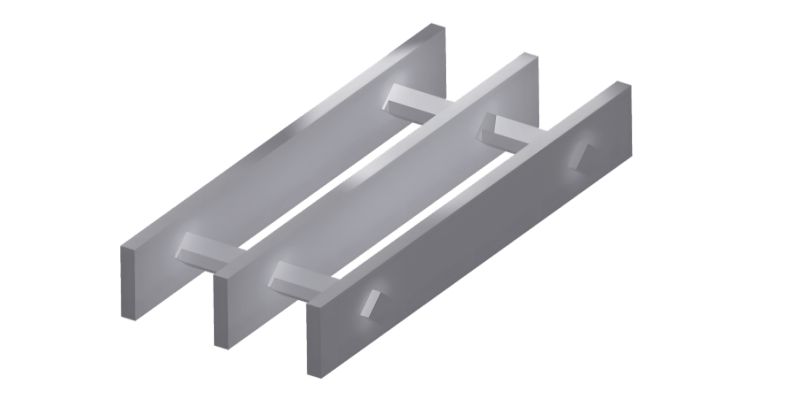

ABX Swage-Locked Grating primarily employs lightweight aluminum material. We provide three different bar shape configurations to meet various requirements. Choose from standard Rectangular bars, efficient I-Bar profiles, or our specialized T-Bar design called SAFE-T-GRID®. Our inventory includes all necessary compatible accessories. These components guarantee seamless integration of your selected grating into any architectural or industrial design scheme.

Our Aluminium Grating is certified slip-resistant and has undergone ASTM testing for strength, so you don’t need to worry about it bending and snapping.

Specifications

Material: Stainless Steel Grating / Aluminium Grating / Carbon Steel Grating.

Finish: Mill finish, Clear Anodized, Powder Coated, Galvanised

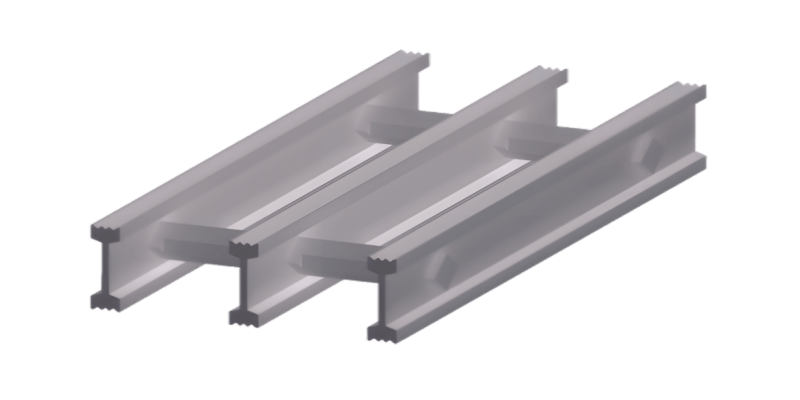

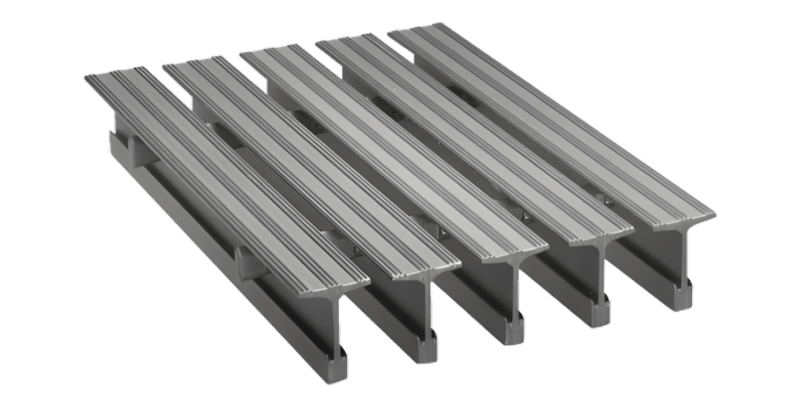

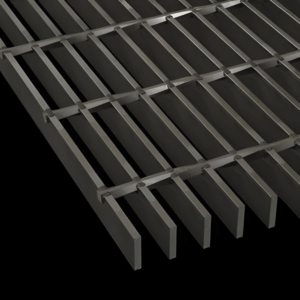

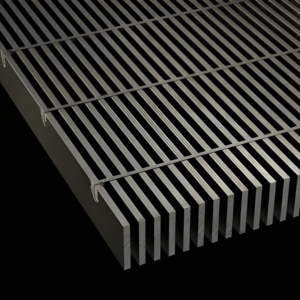

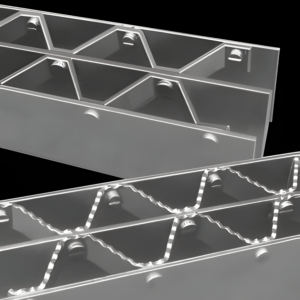

Bearing Bar Type: Flat-Bar, I-Bar and T-Bar

Surface Type: Smooth / Serrated

Thickness: 20mm-60mm

Sizes Available: Standard panels and fabrication available

Flat-Bar / I-Bar / T-Bar Grating Bearing Bar

|

|

|

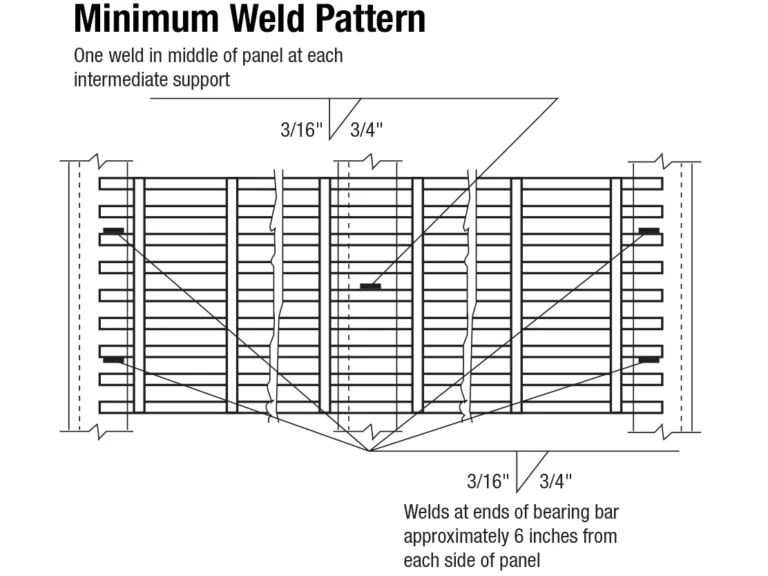

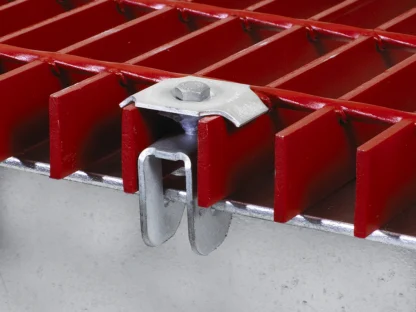

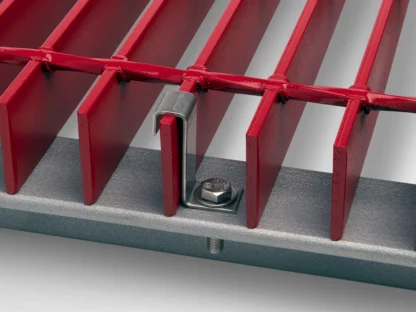

Steel Bar Grating Welding & Fastening Clips

| Welding creates superior permanent installations, while mechanical fasteners (also known as grating clips) provide solutions when grating must be removable or welding is impractical. The recommended weld pattern (illustrated to the right) indicates minimum fastener spacing for pedestrian applications. Vehicular applications typically require additional welding, with specific size and spacing requirements determined by the project’s specifying authority. |  |

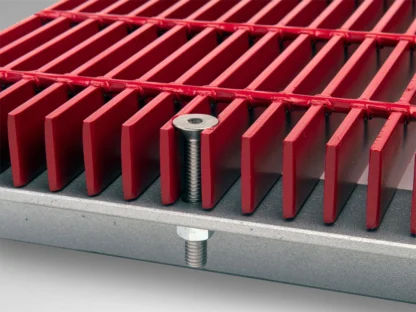

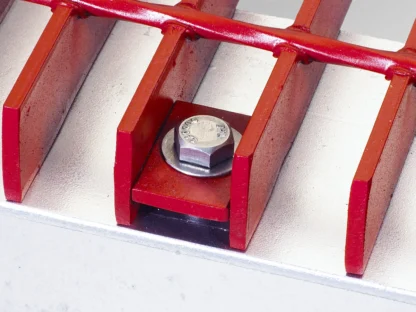

These bent clips, which bridge two bearing bars, are available in galvanized steel, stainless steel, or aluminum. They feature standard 5/16″ bolt holes. Bolts, screws, or other connecting hardware are not included and must be supplied separately. |  The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to accommodate bolt shoulders. Flat head screws or self-drilling fasteners are not included and must be supplied separately. |  These plates, pre-punched with holes, are welded between the bearing bars to facilitate bolting to the supporting structure. Bolts, screws, or other connecting hardware are not included and must be supplied separately. |

Installed from the top surface of the grating, these mechanical fasteners create a friction connection with the supporting flange. “G” clips are easily installed without the need for drilling or welding. |  This formed clip is designed to capture two bearing bars spaced at 11/16″ on center. Flat countersunk screws and other required fastening hardware are not included and must be supplied separately. |  A narrow formed clip used to capture a single bearing bar in applications with limited spacing, typically 11/16″ on center. Cap screws and other necessary fastening hardware are not included and must be supplied separately. |

| Bearing Bar (mm) | Cross Bar (mm) | Center Pitch (mm) |

|---|---|---|

| Flat-Bar Grating | ||

| 25 × 2 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 25 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 25.4 × 4.76 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 30 × 5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 31.75 × 4.76 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 32 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 35 × 5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 38 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 38 × 5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 40 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 40 × 4 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 40 × 5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 40 × 12 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 45 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 45 × 5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 50 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 50 × 4.5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 55 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 60 × 3 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 60 × 12 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 65 × 4.96 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 65 × 5 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| I-Bar Grating | ||

| 26.8 × 6.25 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 25.4 × 6.35 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 65 × 6.35 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 50.8 × 6.35 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| T-Bar Grating | ||

| 32 × 60 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

| 28 × 52 | 8 × 8 | 30 × 100, 40 × 100, 60 × 100 |

Advantages of Aluminium Swage-Locked Grating

Lightweight Construction

Aluminum grating weighs only one-third of steel, significantly reducing structural load. This makes it ideal for rooftop platforms, elevated walkways, and cantilevered structures while substantially cutting transportation and installation costs.

Superior Corrosion Resistance

The natural oxide layer on aluminum provides excellent protection against atmospheric corrosion without additional coatings. It performs exceptionally well in coastal areas and chemical plants, offering a service life exceeding 30 years.

Excellent Conductivity

Aluminum’s inherent electrical conductivity ensures safe static electricity dissipation, making it particularly suitable for flammable environments and electronics workshops where anti-static properties are crucial.

Minimal Maintenance

The self-healing oxide layer eliminates the need for regular anti-corrosion maintenance. Lifecycle maintenance costs are reduced by over 70% compared to steel grating.

Eco-Friendly & Recyclable

Aluminum is 100% recyclable with only 5% of the energy required for primary production. This supports green building certifications and sustainable development goals.

Low-Temperature Performance

Maintains excellent toughness at temperatures as low as -50°C without cold brittleness, making it perfect for cold storage facilities and northern严寒 regions.

Aesthetic Durability

The natural silver finish of aluminum provides a modern industrial appearance, while anodizing offers various color options to combine functionality with visual appeal.

Quick Installation

The modular design and lightweight nature enable 40% faster installation compared to traditional steel grating, especially beneficial for renovation projects with tight schedules.

Aluminum Swage-Locked Grating achieves the optimal balance between weight, durability, and maintenance costs through the perfect combination of material properties and innovative manufacturing technology.

Applications Of Swage-Locked Grating

Industrial Platforms & Walkways

Swage-locked grating provides durable flooring for industrial facilities. Manufacturing plants install it as mezzanine walkways. Chemical processing plants utilize its corrosion resistance. Warehouses employ it for elevated work platforms.

Energy & Power Generation

Power plants rely on swage-locked grating for critical areas. Nuclear facilities choose it for radiation zones. Oil refineries install it in process areas. Renewable energy projects specify it for long service life.

Marine & Offshore Applications

Shipbuilders select swage-locked grating for vessel interiors. Offshore platforms depend on its saltwater resistance. Port facilities use it for cargo handling areas. Marine terminals install it in tidal zones.

Transportation Infrastructure

Airports choose swage-locked grating for passenger bridges. Railway stations utilize it for platform edges. Highway maintenance requires it for catwalks. Bridge engineers specify it for inspection walkways.

Water Treatment Facilities

Treatment plants install swage-locked grating throughout. Pump stations use it for wet area flooring. Filtration buildings employ it for chemical resistance. Processing centers rely on its non-slip properties.

Commercial & Public Buildings

Architects specify swage-locked grating for aesthetic appeal. Shopping malls use it for decorative balconies. Stadiums install it for crowd control areas. Public spaces choose it for low maintenance.

Food & Pharmaceutical Industry

Processing plants require swage-locked grating’s cleanability. Breweries utilize its corrosion resistance. Pharmaceutical facilities choose its hygienic properties. Food production areas need its easy maintenance.

Special Applications

Mining operations depend on its heavy-duty performance. Aerospace facilities choose its precision engineering. Research laboratories require its chemical resistance. Emergency services utilize its reliable safety features.

Each application benefits from swage-locked grating’s unique combination of strength, corrosion resistance and maintenance-free performance, making it the preferred choice for demanding environments worldwide.

Reviews

There are no reviews yet.