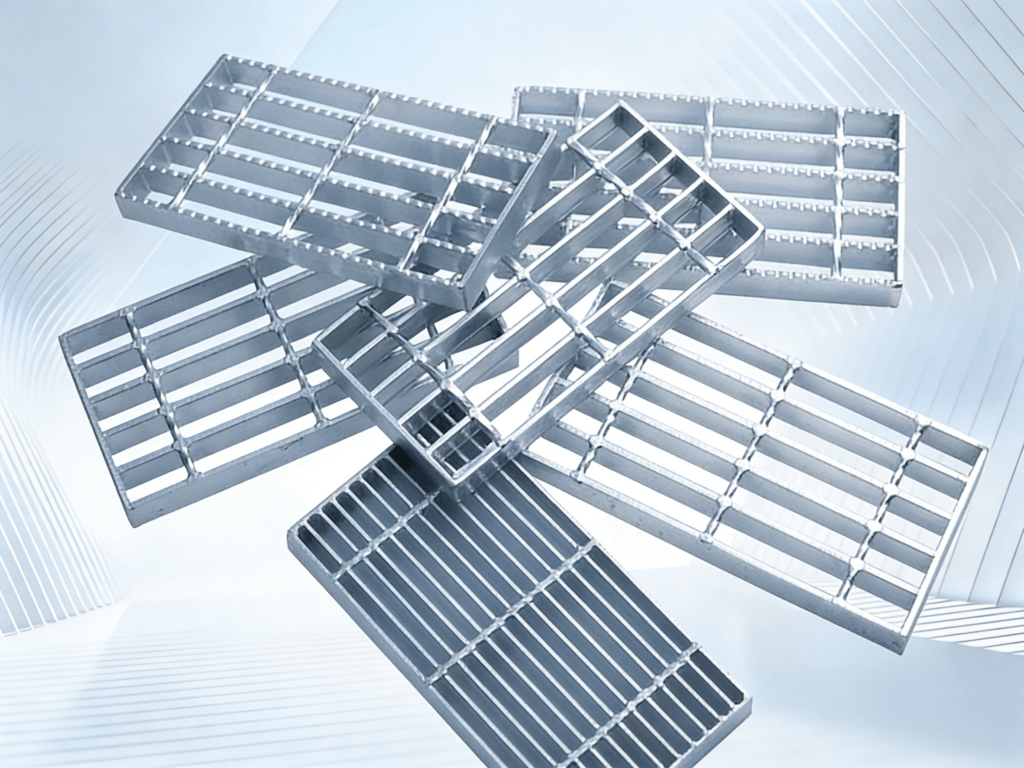

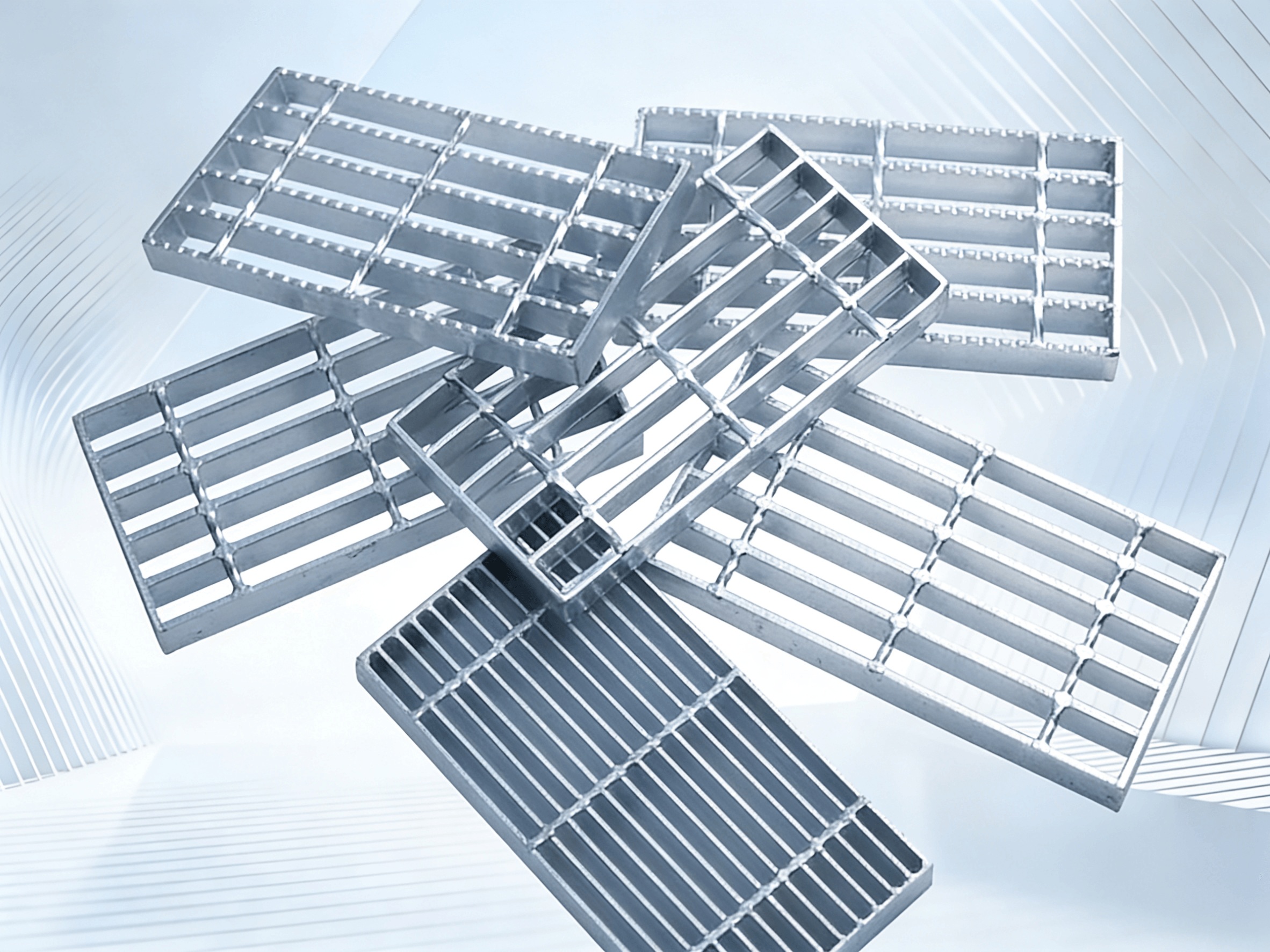

Metal Grating serves as a reliable cornerstone of industrial flooring, supporting industries for decades. It offers exceptional strength-to-weight ratio and durability, allowing easy fabrication into nearly any configuration. The high open area ratio minimizes maintenance, and all grating products remain fully recyclable.

Metal Grating Options

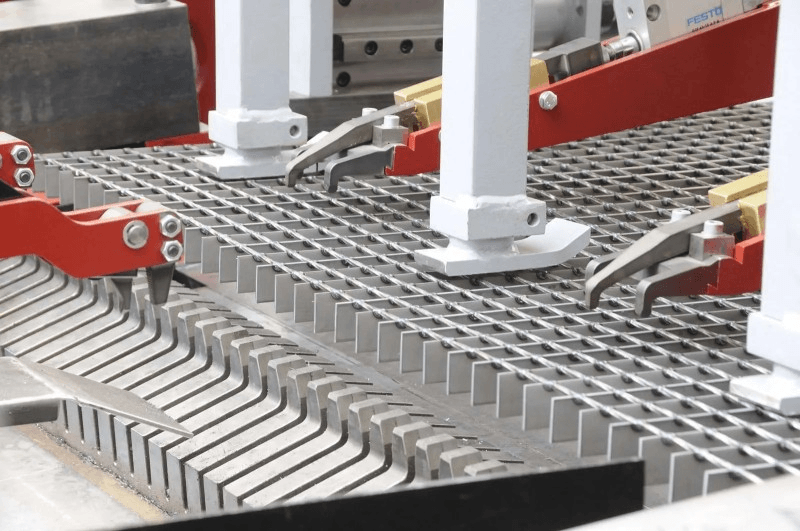

Manufacturing Process: Welded Grating / Press-Locked Grating / Swage-Locked Grating / Riveted Grating

Material: Galvanized Carbon Steel / Aluminum / Stainless Steel

Surface: Smooth surface / Serrated surface

Manufacturing Process

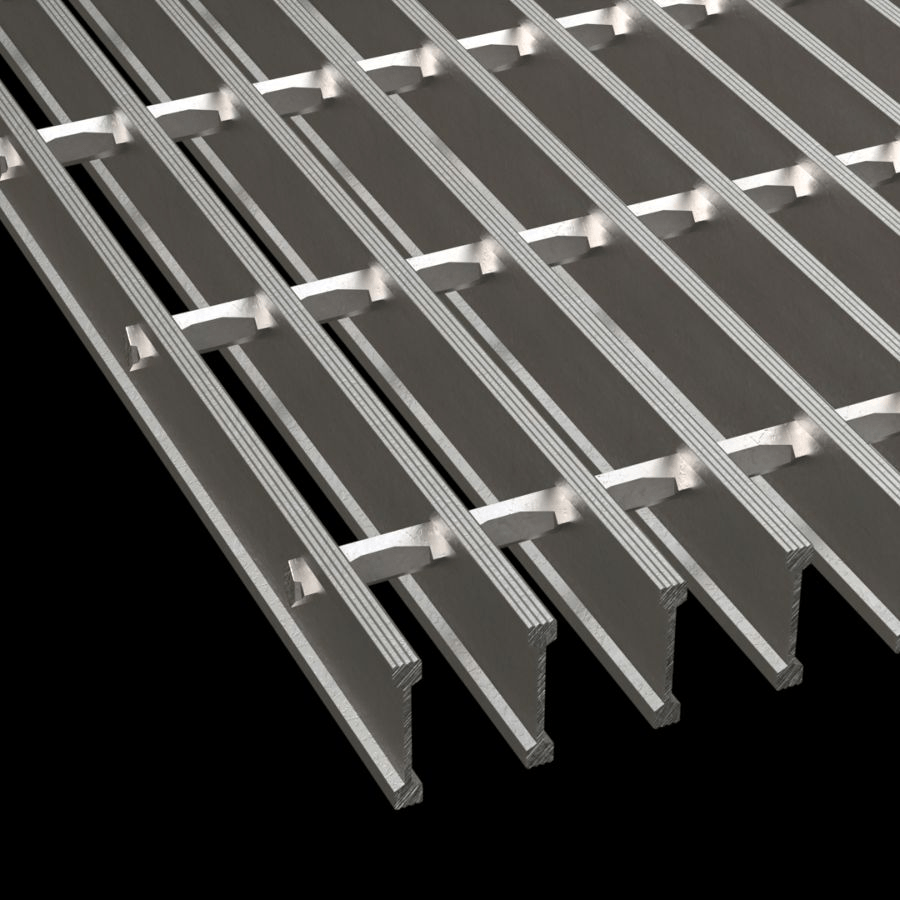

Press-Locked Grating

Workers assemble this grating by inserting pre-punched bearing and cross bars into an interlocking configuration, then deforming the cross bars under intense hydraulic pressure. Available in all materials, this type excels in architectural and ornamental uses.

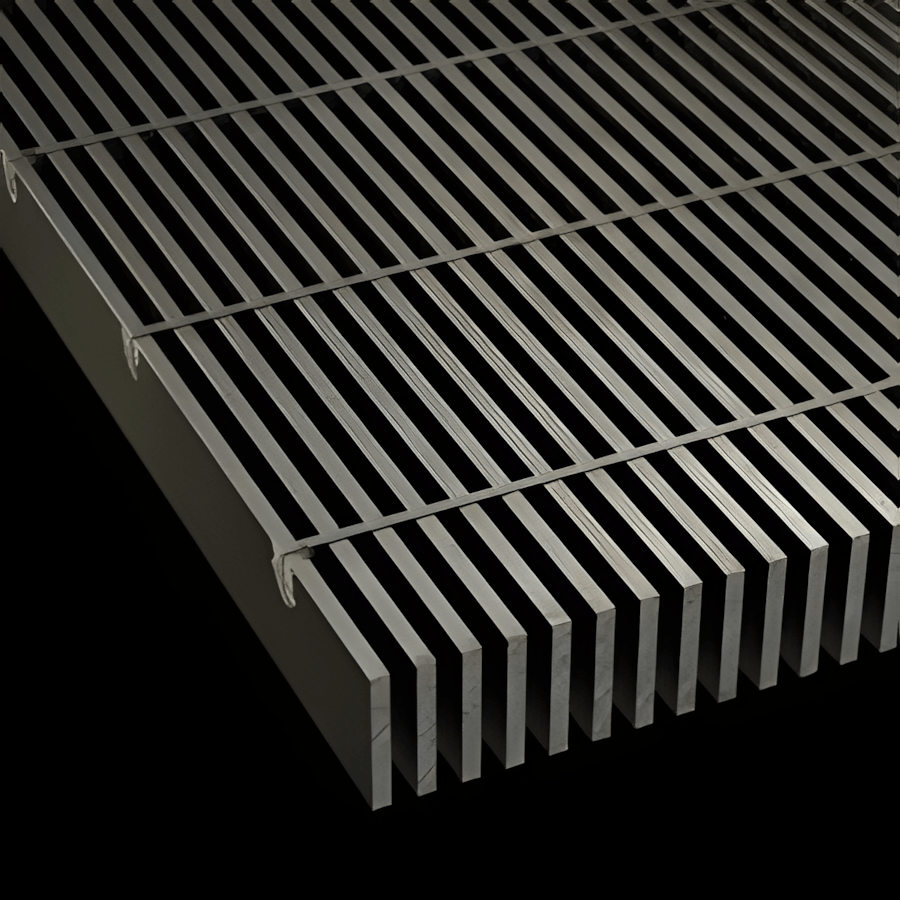

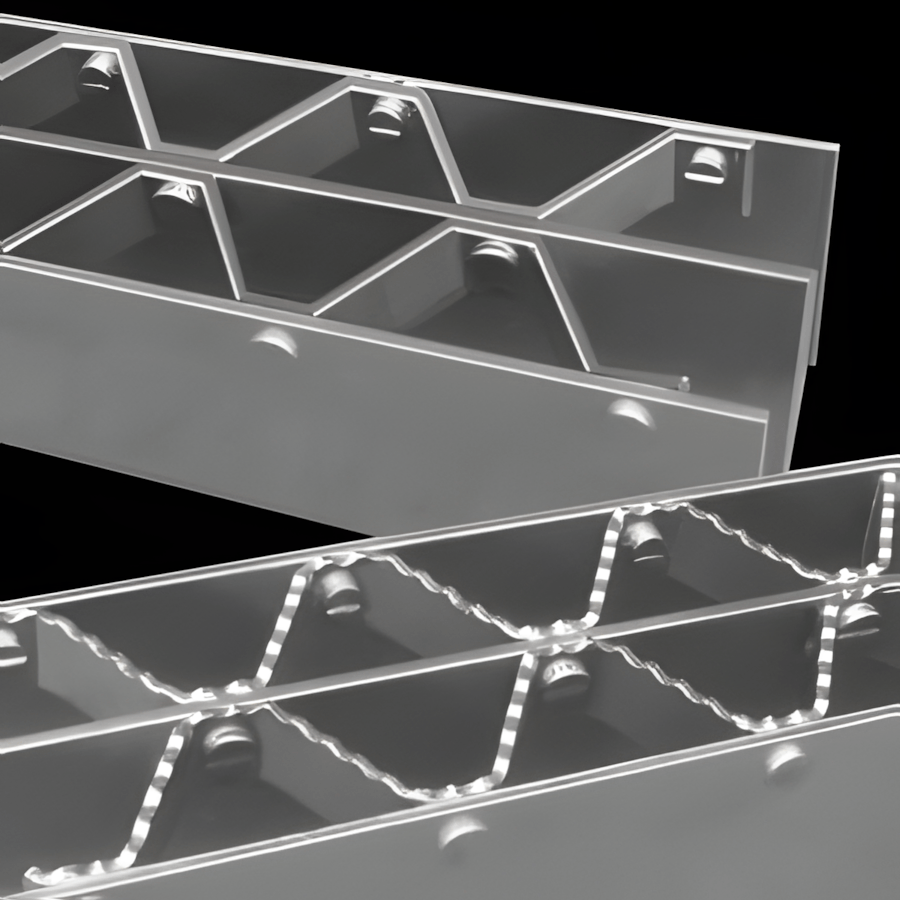

Riveted Grating

Exceptionally durable, this grating uses rivets to join bearing bars and bent connecting bars at contact points. It performs excellently under impact loads and repetitive traffic.

Materials of Metal Grating

Manufacturers create bar grating by assembling equally spaced metal bars with connecting cross members. The three most common materials include mild carbon steel, 6000 series aluminum, and 300 series stainless steel. ABX Metal can also produce grating from other specialty metal alloys. Contact us to discuss your specific needs.

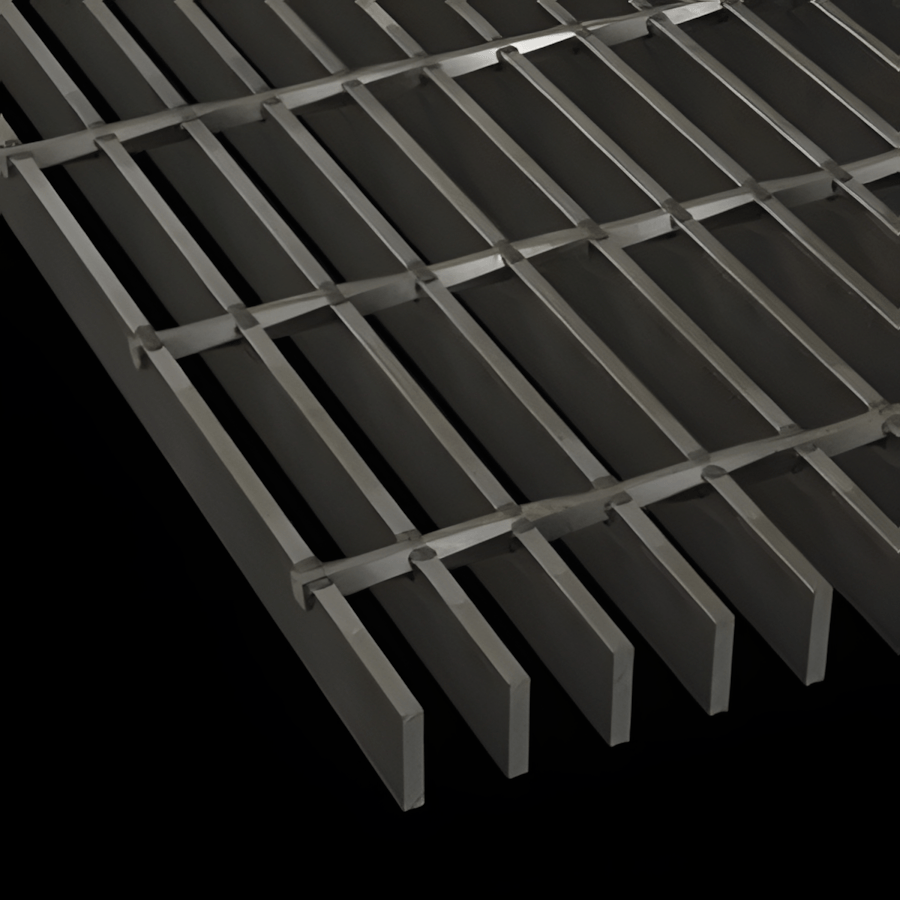

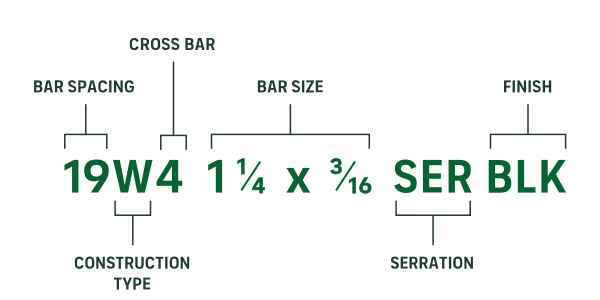

Understanding Metal Grating Nomenclature

Bearing Bars: Load-carrying bars that determine the grating span

Cross Bars: Connecting bars that run along the grating width

Finish: Applied coating, such as painted black or galvanized

Serrated: Notched surface for slip resistance

Widths: Overall dimension perpendicular to bearing bars

Span: Distance along the direction of bearing bars

Banding: Bar matching bearing bar size to close open ends

Kick Plate: Flat bar welded to the outer edge, projecting above the grating

Custom Fabrication

ABX Metal serves as your premier full-service grating supplier. Whether you need stock panels or custom fabrication, we cover all your requirements. As your trusted partner, we guide you through a seamless journey from concept to fully fabricated, ready-to-install grating.

We deliver tailored solutions that meet your project specifications. Our Sales, Engineering, Drafting, and Fabrication teams collaborate closely with you to realize your vision. From initial structural drawings to detailed grating plans, we use cutting-edge computer-aided design and 3-D software to ensure precision and efficiency throughout the process.

As both manufacturer and fabricator, we provide comprehensive “One Source” solutions for all grating needs. Our commitment to continuous improvement drives us to maximize efficiency at every stage.

Your satisfaction remains our top priority. We deliver exceptional products and service throughout your project.

Fabrication Examples

Designing circular layouts and radial platforms

Cutting to size

Creating cutouts for panel penetrations

Welding banding, kick plates, or nosings to grating

Fabricating stair treads

Adding custom features like checker plate, lifting handles, and hinges