Description

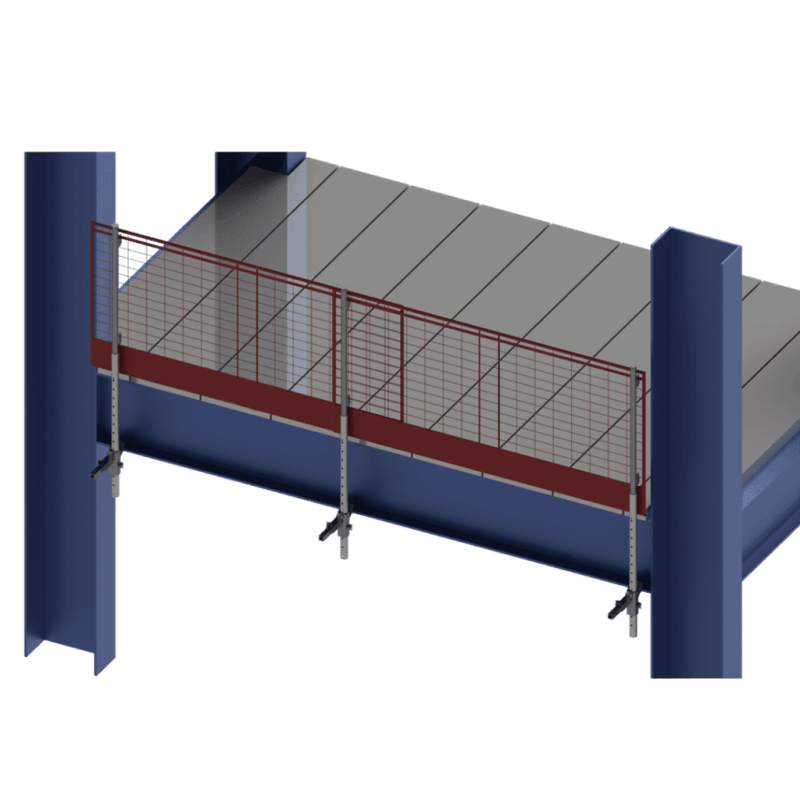

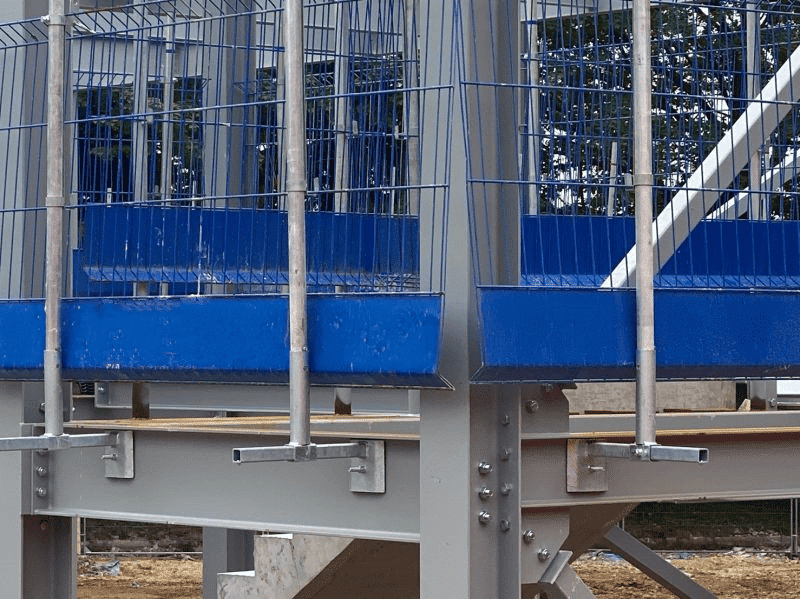

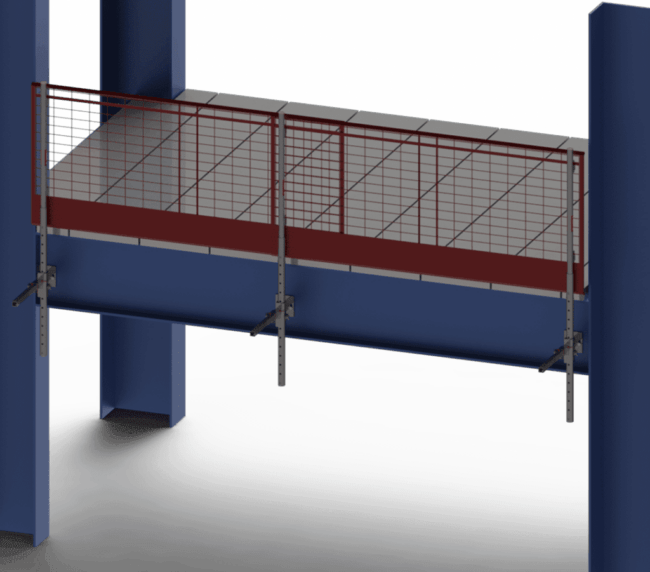

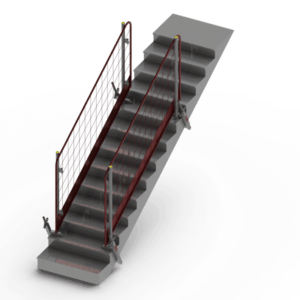

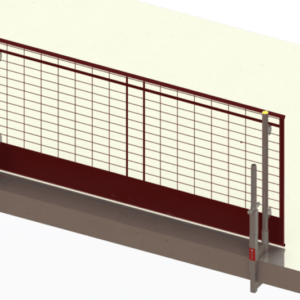

Steel structure require specific edge protection barrier. These barriers ensure worker safety during construction. They also protect maintenance personnel. Steel structure edge protection creates essential secure work environments.

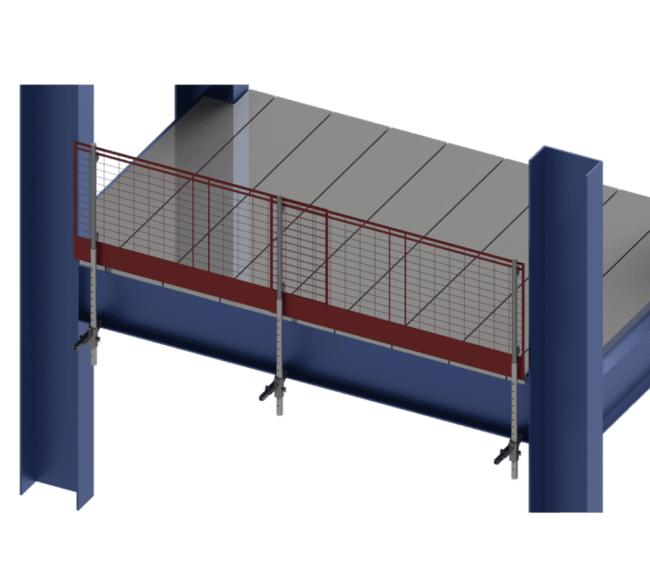

Edge protection systems work with steel construction methods. They feature adjustable components often. This allows easy adaptation to various heights. Systems also adjust to different angles. They fit multiple steel framework configurations. This flexibility lets workers access all areas safely.

Steel Structure Edge Protection Barrier Solutions

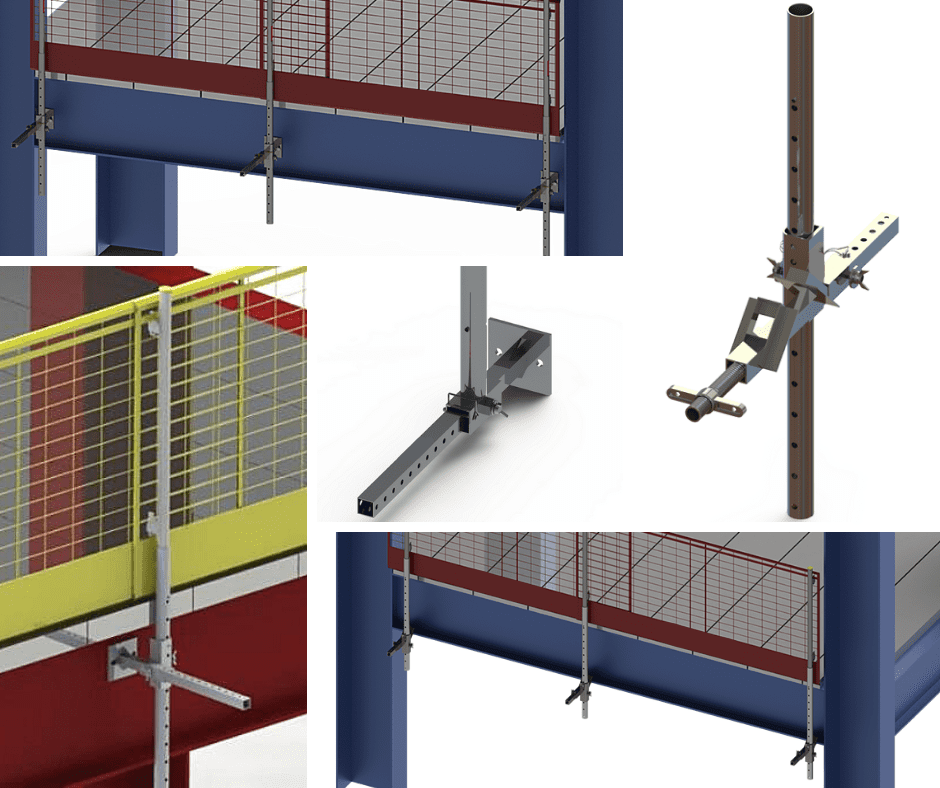

We offer several operation methods for steel structures. Choose top bolted systems for secure attachment. Clamped systems provide quick installation. Welded systems offer permanent horizontal steelwork connections.

These systems classify by their fixing operation.

|

|

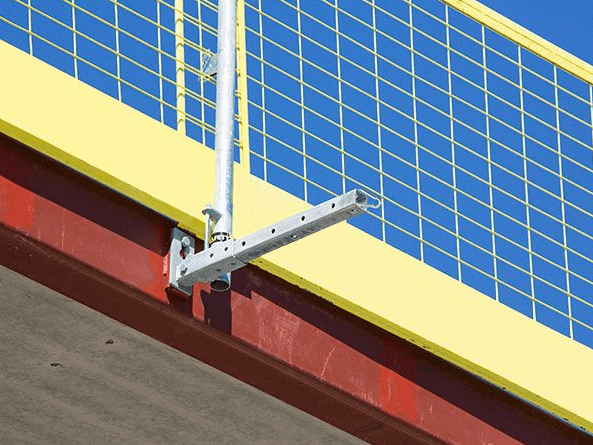

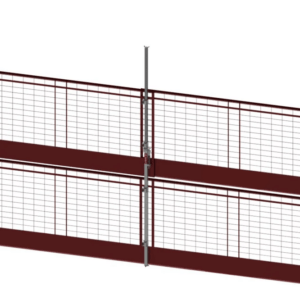

| CLAMP ON STEEL BEAMS This method uses I-Beam brackets as fixing components. Workers clamp them to horizontal beams easily. An adjustable screw simplifies the setting process. | PRE-INSTALLATION ON STEEL BEAMS This approach uses I-Beam Facade Brackets. Workers bolt them onto steel beams directly. Teams can complete setup at ground level beforehand. |

Why Choose Our Steel Structure Edge Protection Barrier?

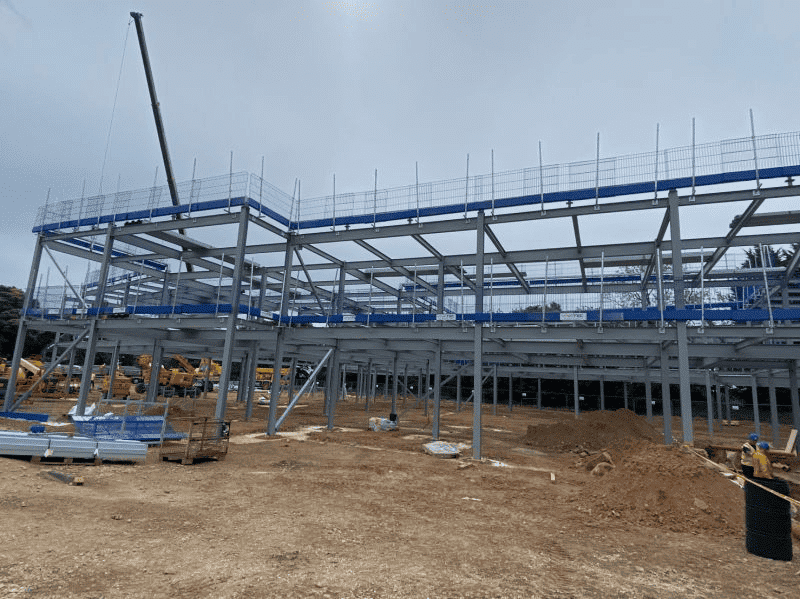

ABX began edge protection work in 2017. Our systems serve concrete structures effectively. They protect steel structures reliably. Frame structures also use our solutions. Formwork and stairways benefit too.

We prioritize quality assurance highly. Quality control remains our top business priority. This ensures highest product quality always. Our team inspects raw materials regularly. They check finished goods thoroughly. Incoming materials undergo verification. Outgoing products meet all standards.

ABX systems accommodate several applications. Surface-mounted installations work well. Non-drilling clamps avoid anchor fixings completely.

Project Safety Improvement

Choose ABX for your steel structure projects. We improve worksite safety conditions significantly. Our products protect your workers effectively. We supply more competitive prices always. Our exceptional products beat local market offerings.

Customer Service Commitment

We provide excellent customer service consistently. Reach us by phone anytime. Email communication works well too. We respond within twenty-four hours always.

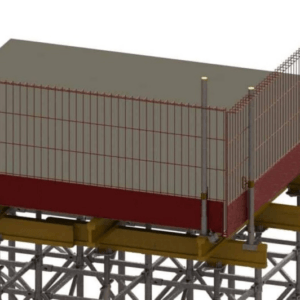

Steel Structure Edge Protection Barrier: Fast Installation

ABX systems install at ground level often. This occurs before steel frame erection. It significantly reduces height work risks.

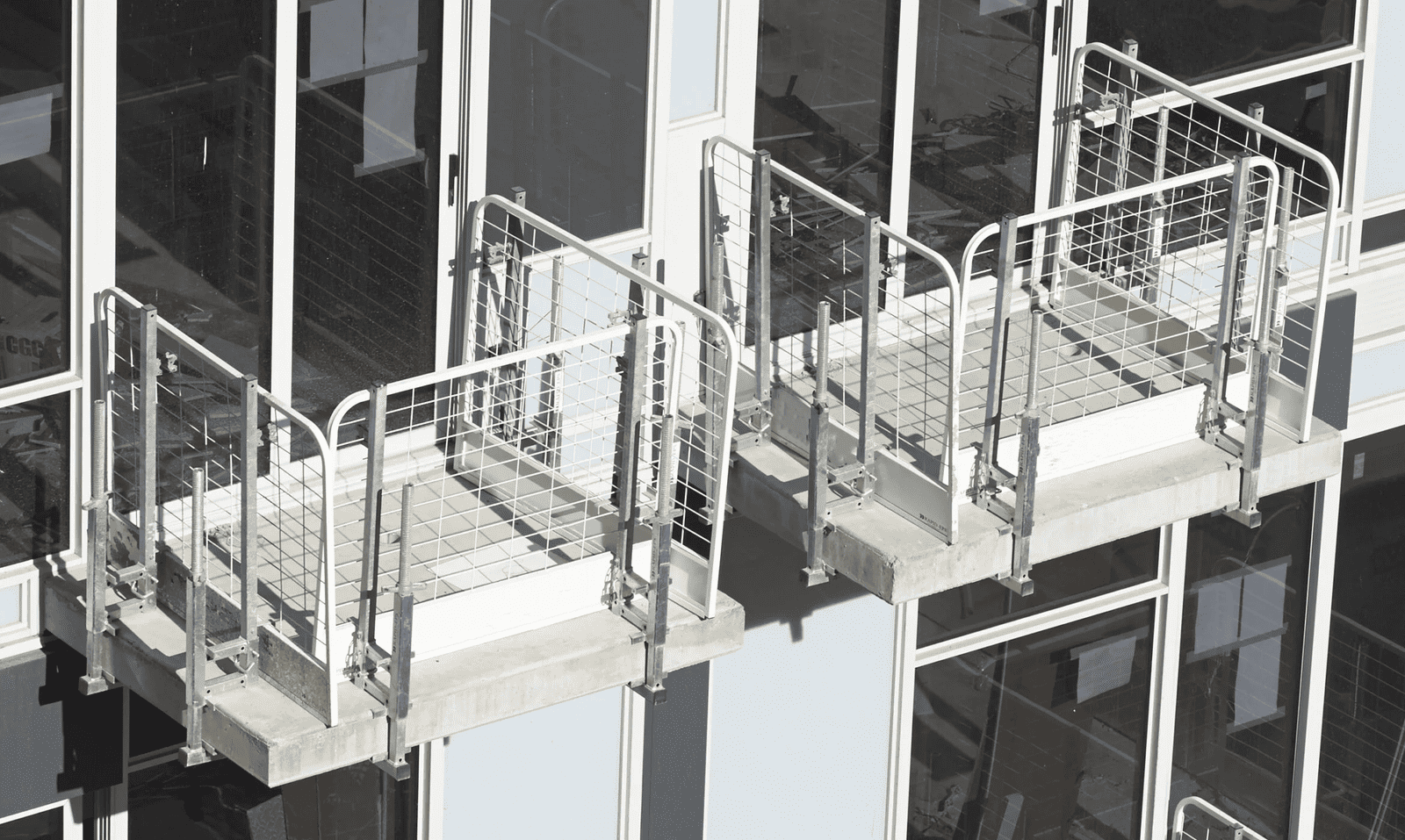

I-beam Facade Bracket System Details

The fixing component uses an I-beam facade bracket. Workers anchor it to the steel column’s edge. Teams should check steel sections carefully. Pre-drilled holes need correct spacings. Secure all components firmly.

Make positional adjustments before attachment. Vertical adjustments complete easily. Leave minimum gap requirements. This prevents later repositioning needs.

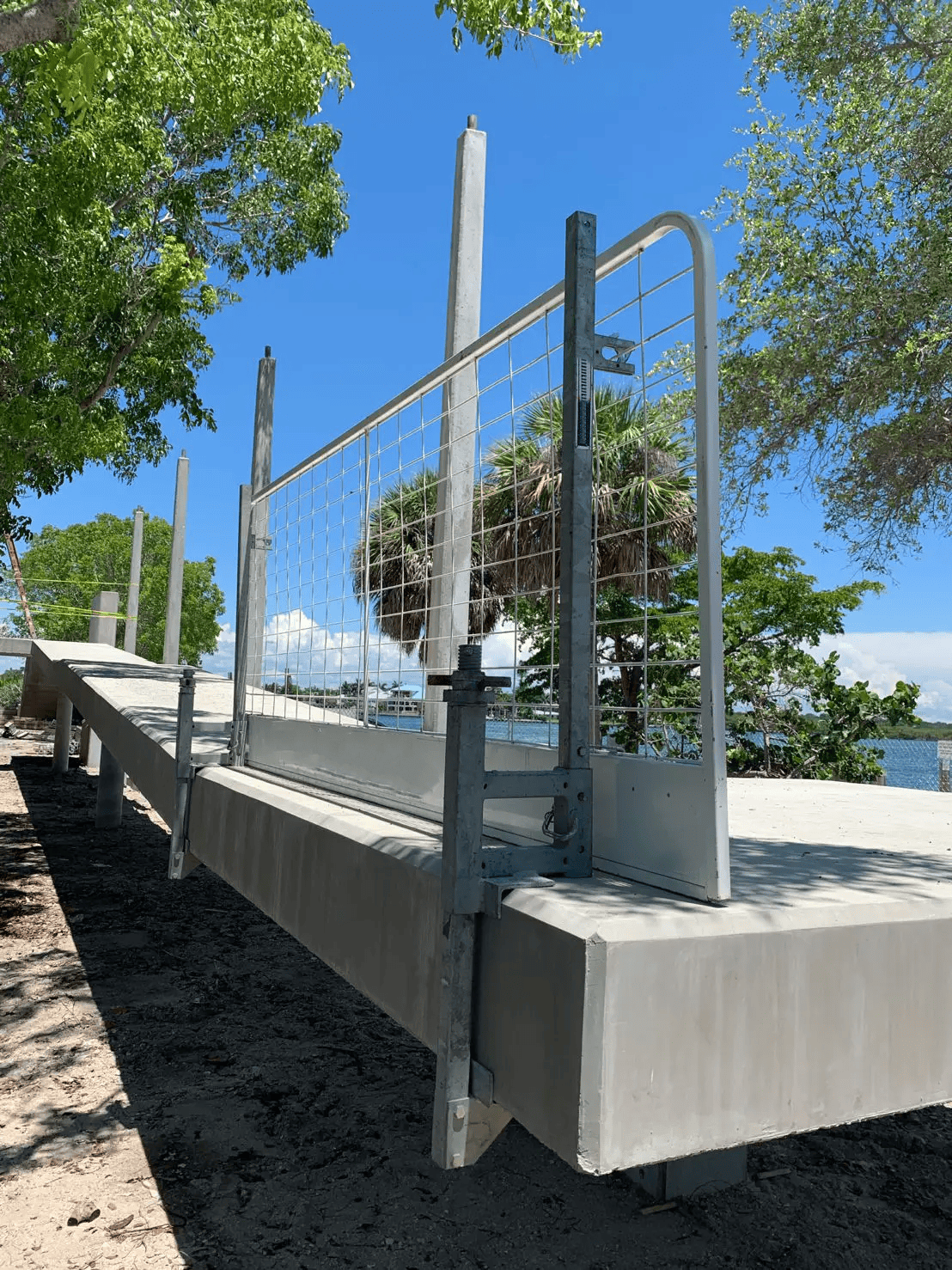

Surface Treatment Process

All metal products receive surface treatment. This occurs before shipping always. Treatments achieve color consistency. They provide corrosion resistance too.

Common Treatment Methods

Powder coating serves as common treatment. Zinc galvanizing also protects effectively. We pre-treat all metal surfaces first. This ensures coating durability. Long-lasting performance results consistently.

Powder Coating Definition

Electrostatic powder coating sprays plastic powder. It increases mesh barrier luster noticeably. Protective coating attaches to surfaces securely.

Hot-Dip Galvanizing Process

Steel immerses in molten zinc baths. This creates durable zinc alloy layers. Tough protection forms completely. It provides maximum outdoor corrosion resistance. Steel withstands harsh environments reliably.

Reviews

There are no reviews yet.