Description

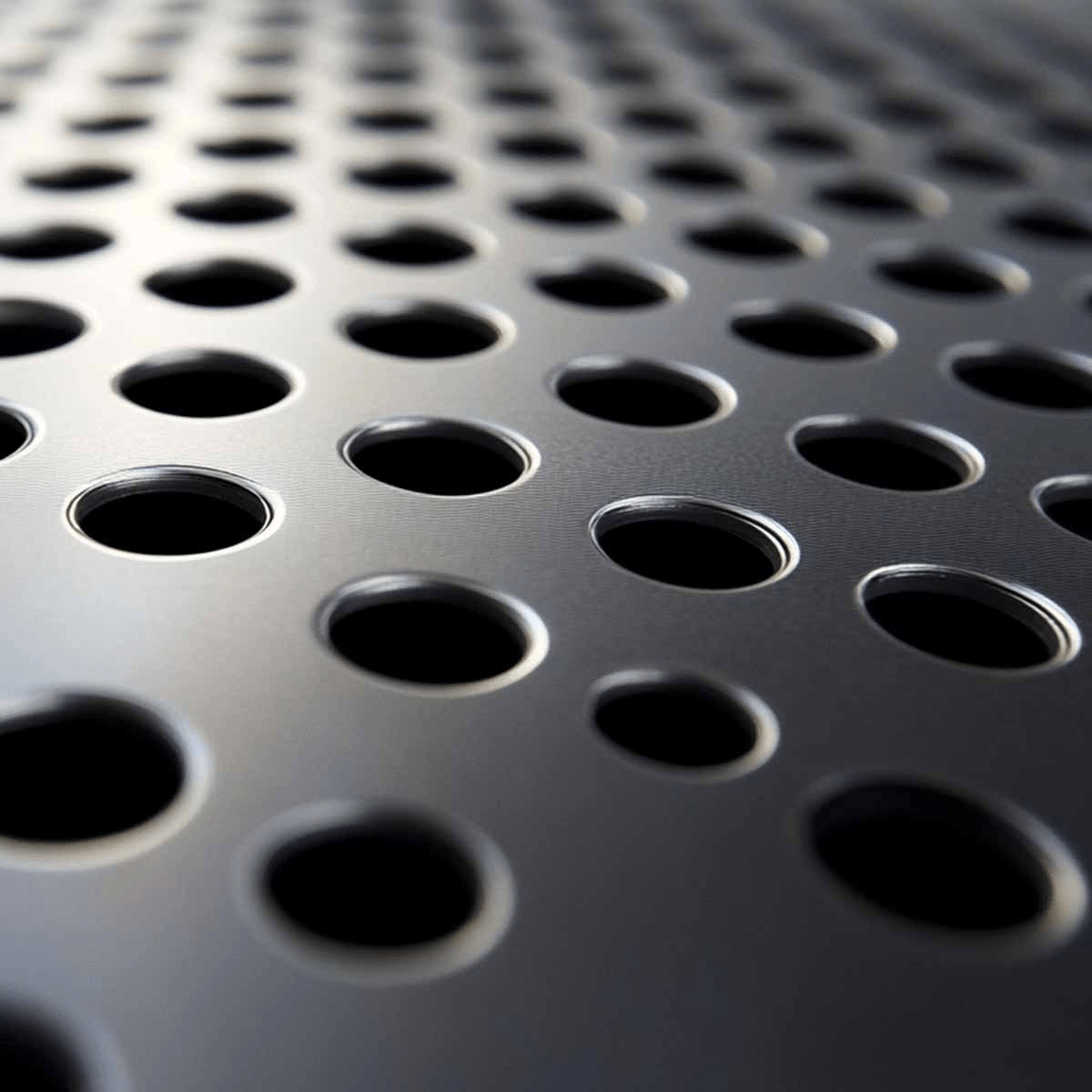

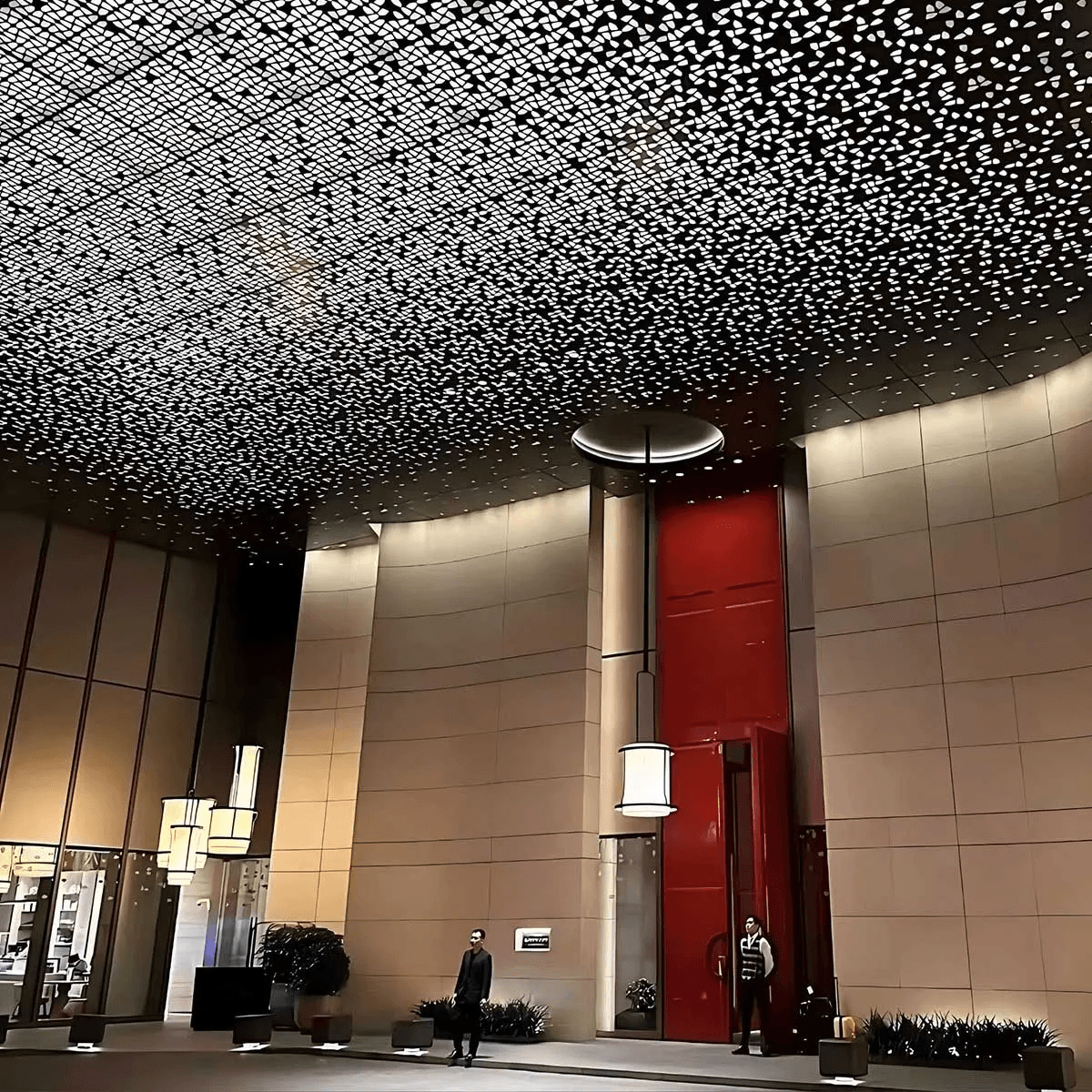

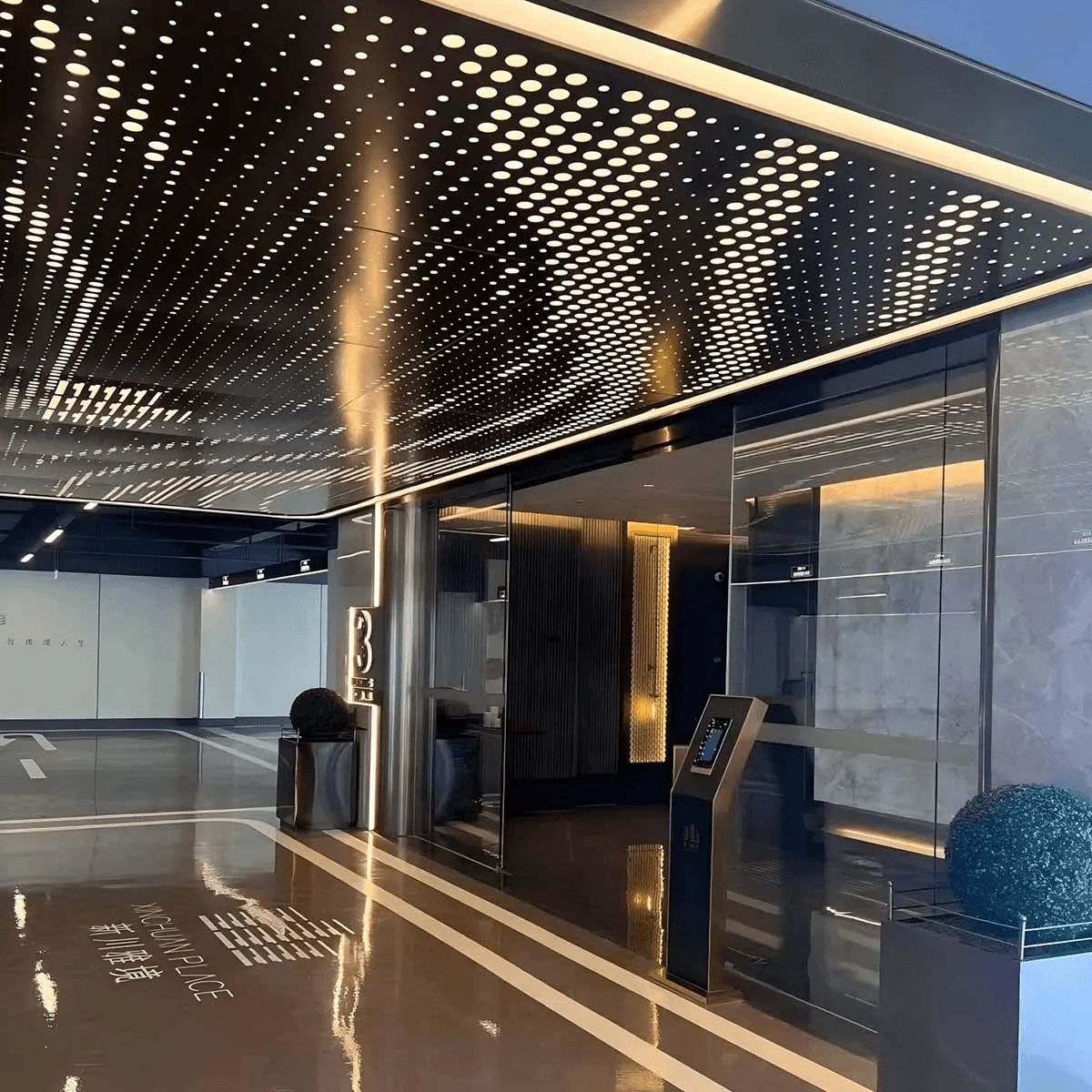

Aluminum Perforated Ceiling Panel improve airflow and sound quality. They also enhance the look of any interior space. Many styles are possible with them. They work well in any home. They add extra style and function wherever installed.

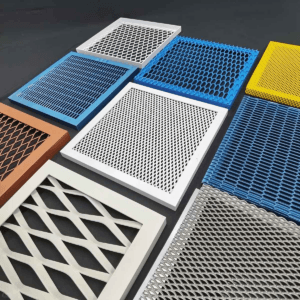

Perforation Arrangements for Metal Ceilings

A Wide Range of Perforated Patterns

Choosing the right perforations makes a space pleasing. It affects how a room looks and operates. Consider several factors during your selection process.

Hole Shapes

Most businesses use round, square, or slotted perforations. Clients may also request custom designs. The ceiling style should be distinctive. The ventilation must function effectively. The plan must achieve both goals.

Hole Sizes and Spacing

Hole diameter and spacing impact light, air, and noise. These features let ceilings meet any area’s needs. They fulfill both functional and design requirements.

Custom Designs

The spacing and diameter of holes direct sound and air. They also influence sunlight penetration. Varied perforations allow ceilings to serve any space. They address functionality and aesthetics together.

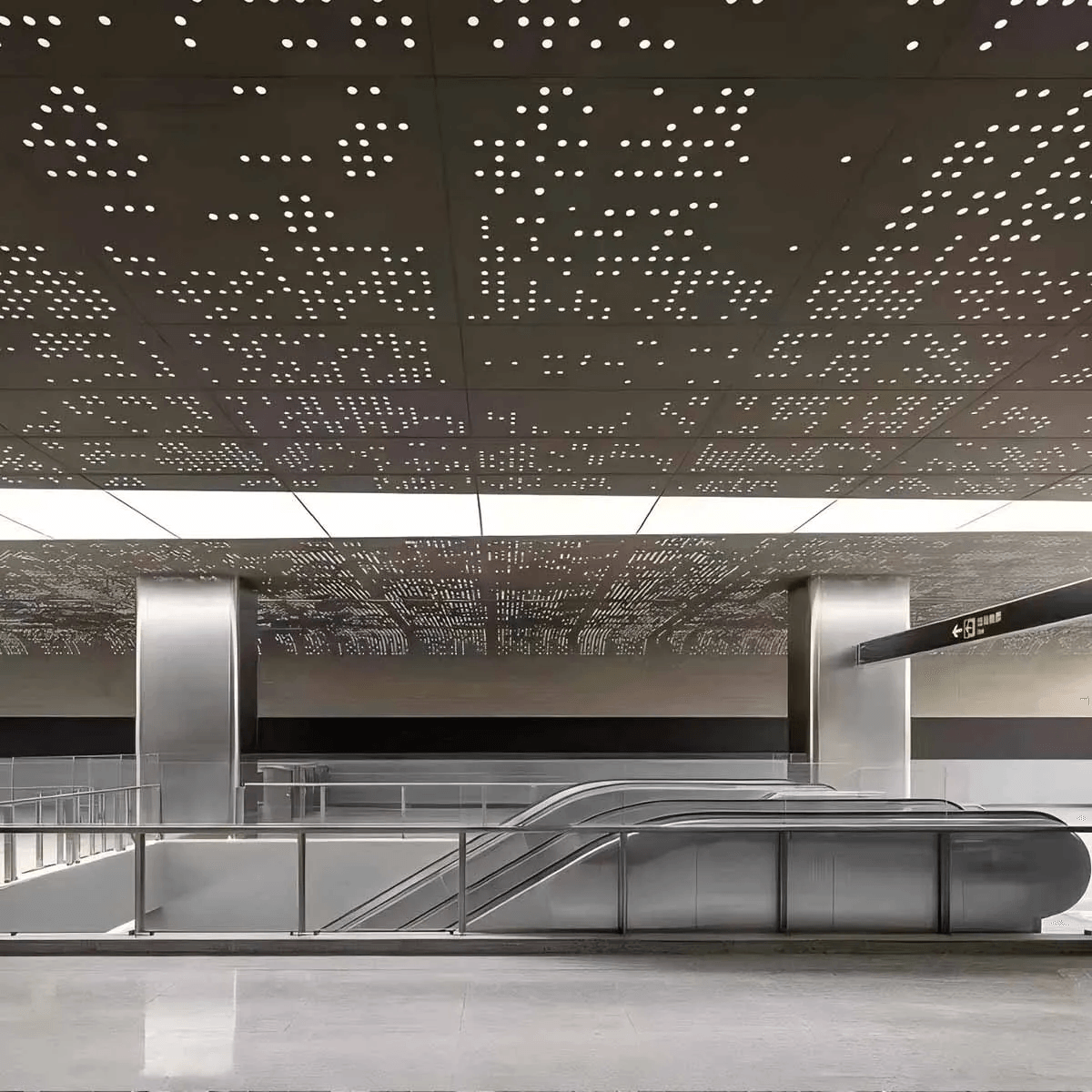

Acoustic Optimization

Pattern design can improve sound quality. It controls the size of exposed open area. Patterns on acoustic panels increase sound absorption. They enhance feelings of comfort and tranquility.

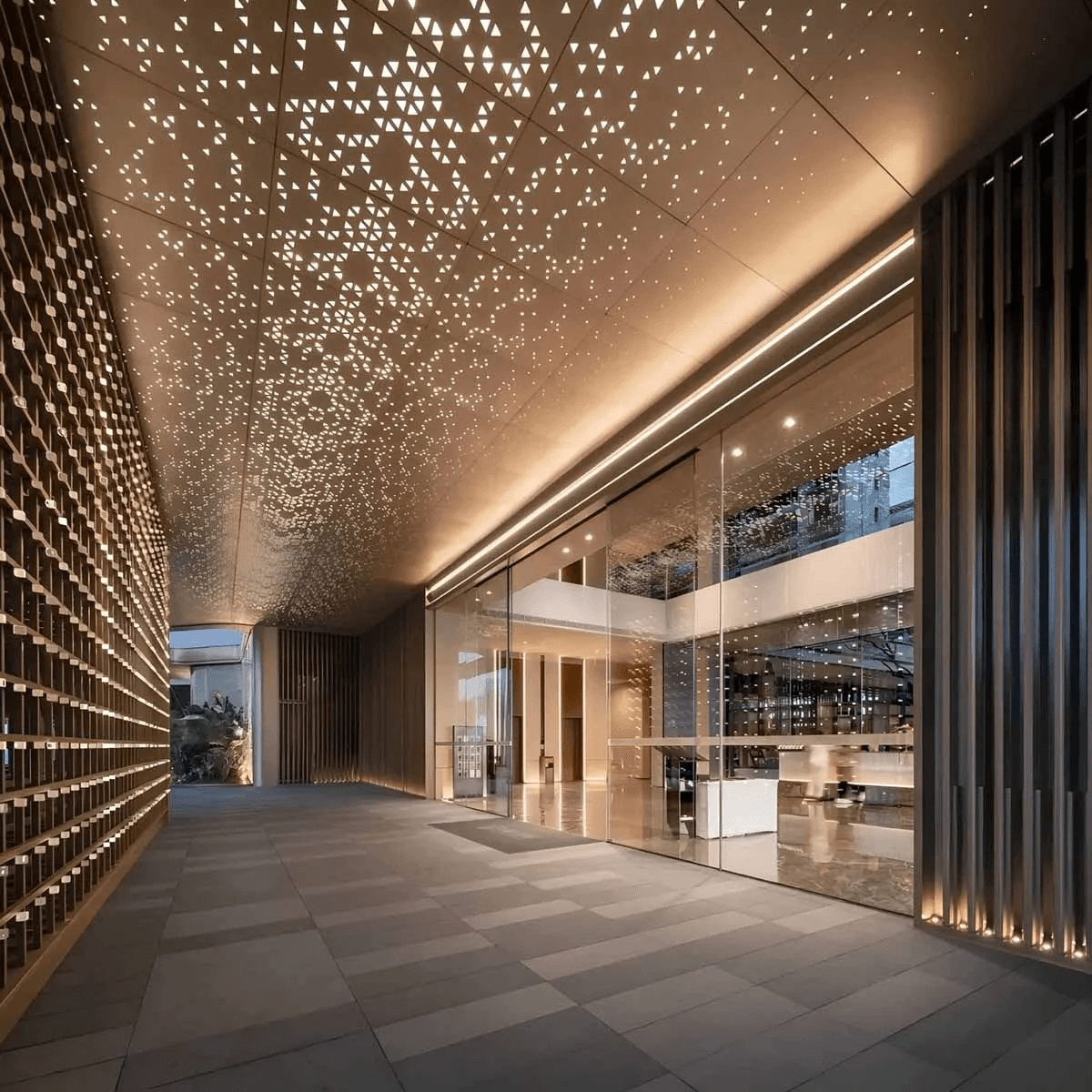

Visual Impact

Patterns create dynamic texture in interior spaces. They produce interesting shadow effects. Smart design changes make ceilings both usable and beautiful. They decorate ceilings more attractively.

Material Efficiency

Optimized perforation patterns minimize material waste. They maintain strength and structural integrity. This ensures the ceiling’s functional performance. It also supports efficient, eco-friendly design solutions.

Our architectural metal ceilings solve aesthetic and acoustic problems. They offer endless design possibilities, meet basic building needs reliably. They represent smart, versatile solutions for diverse spaces.

Specifications

| Standard | GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN |

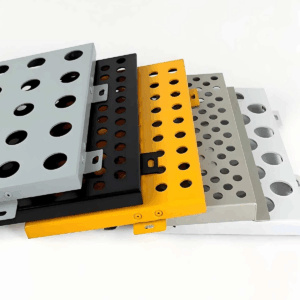

| Thickness | 0.8 mm – 3.0 mm | |

| Height/Width | 30 mm – 1850 mm, Customized | |

| Length | 1220 mm – 3000 mm, Customized | |

| Tolerance | ±1% | |

| Alloy Grade | 1050, 1060, 1100, 3003, 3105, 5052, etc. | |

| Technique | Cold Rolled | |

| Finish | Powder Coating, PVDF Coating | |

| Colors | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc. | |

| Edge | Mill, Slit | |

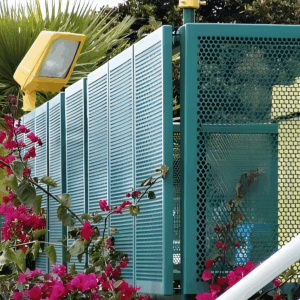

| Applications | Ceiling, Wall Panel, Facade, Interior Decorations | |

| Packing | PVC + Waterproof Paper + Wooden Package |

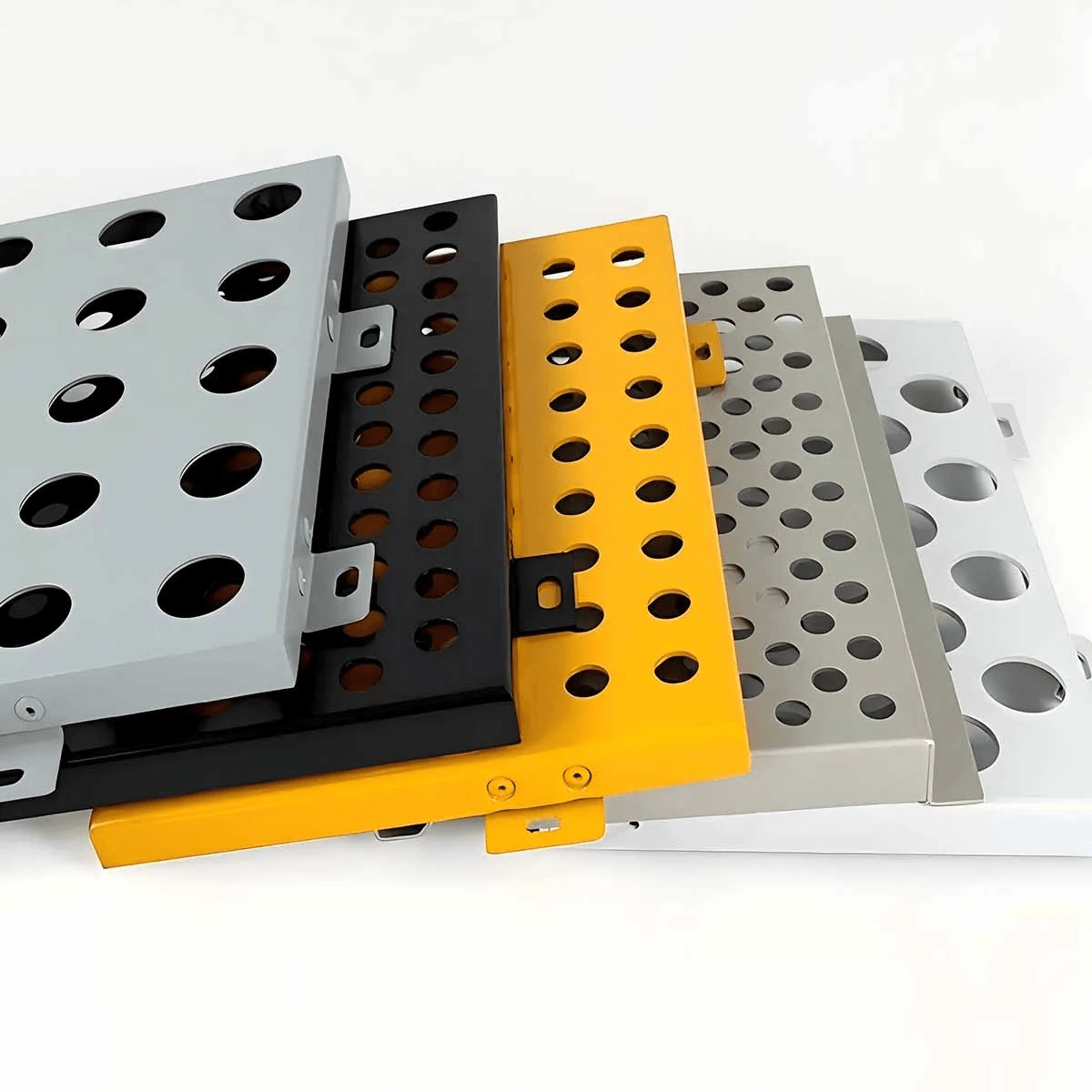

Color Options for Aluminum Perforated Ceiling Panel

A Wide Range of Color Options

Choosing the right finish matters greatly in interior design. Anodized finishes offer smoothness and strength. Powder-coating provides various interesting finishes. These options add beauty and physical durability.

Anodized Finish

Electrolytic and chemical processes form an oxide layer. This extra film coats the metal surface. Hard-anodized coatings cover aluminum effectively. They resist rust and decay better than ordinary coatings.

Powder Coated Finish

Powder coating often changes a finish. It also increases durability significantly. Electrostatic technology applies powdered paint. The powder bonds to pre-heated material. You can select any color shade easily. This method offers excellent handling benefits.

PVDF Coating Finish

PVDF coating shields metal ceilings from damage. It helps bright colors stay fresh for a long time. This finish resists weather, sun damage, and corrosion reliably. It maintains a beautiful, flexible appearance over many years.

Brushed & Polished Finishes

A brushed or polished finish gives a modern look. It also increases material durability. The polished surface reflects light attractively. These features improve both functionality and architectural appearance.

Wood Grain & Custom Textures

Wood grain and unique patterns create a natural feel. They make ceilings appear modern and durable. Their versatile designs suit many architectural spaces. These attractive patterns look good and remain highly useful.

Selecting a finish gives your space a nice look. It also provides long-term protection. Choose anodized, powder-coated, or PVDF finishes. Consider brushed, polished, or custom textures. These options match your design needs and environmental conditions perfectly.

Processes Of Making Perforated Metal Ceiling Panel

High-Precision Metal Fabrication

Perforated metal ceiling tiles offer various patterns and acoustic benefits. Would you like to understand their manufacturing process? Follow the steps below to discover their creation.

Design Conceptualization

This process begins with unique pattern development. Designs balance aesthetics, function, and room themes. Designers experiment with shapes and sizes. This achieves striking visual impact. It also optimizes sound quality.

Material Selection

Manufacturers use versatile aluminum or classic copper. Durable stainless steel is another common option. These materials balance strength with aesthetic appeal. This allows designers to fulfill their creative vision.

Perforation Pattern Design

The surface pattern impacts visual and acoustic performance. Advanced algorithms determine the hole layout. They maximize density for optimal light diffusion. This also improves sound environments and heat flow.

Precision Perforation

High-tech computer-controlled machinery executes the design. It creates holes with exact diameters and spacing. This achieves specific visual and acoustic effects precisely.

Finishing Touches

Workers finish aluminum perforated ceiling panel after perforation. This provides protection and eases cleaning. Edge refinishing enhances appearance. Treatments ensure panels last longer. They also preserve the original design for diverse applications.

Quality Control

Strict controls ensure every panel meets high standards. Inspections verify finishing quality and pattern accuracy. Only top-quality products reach the market. Any items failing requirements are scrapped.

Installation and Integration

Expert installation ensures structural integrity. It also guarantees the best visual results. The elegant design complements lighting and air conditioning. It integrates seamlessly with the overall building layout.

Design, precision, and quality together create these aluminum perforated ceiling panels. They are both beautiful and highly functional. This seamless process delivers decorative, durable acoustic ceilings. They install perfectly in any interior space.

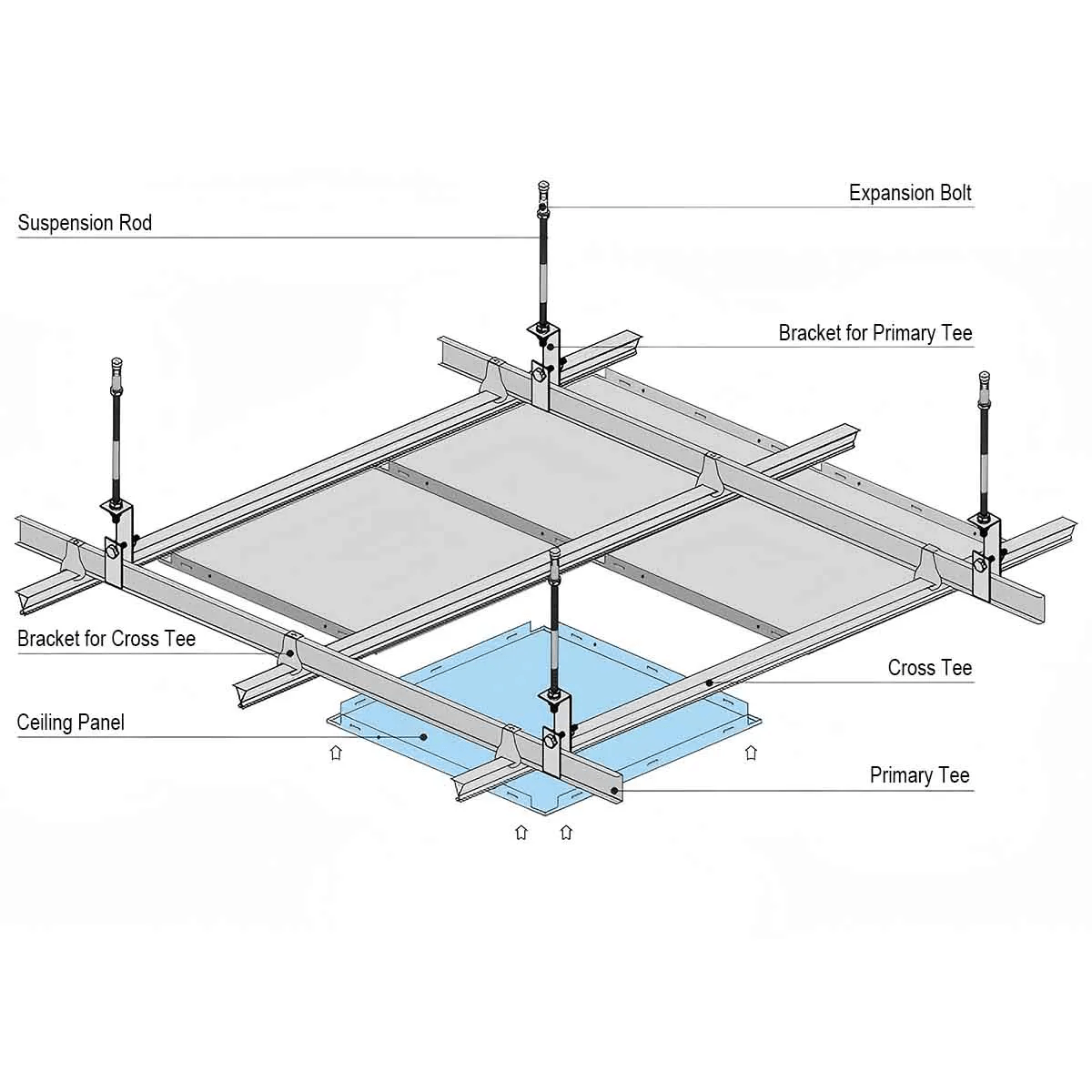

Installation Guide for Metal Ceilings

Step-By-Step Procedure for Installing

Follow a specific sequence of steps. This ensures a secure, flat, and aesthetic result. The guide below provides a step-by-step process. It includes key installation parts and our recommended accessories.

Step 1: Prepare the Ceiling Layout

First, inspect the ceiling area. Ensure the surface is clean, dry, and unobstructed. Outline your ceiling height and grid plan. Achieve this through careful measurement. Follow your design plan closely.

Step 2: Install Suspension Rods

Drill holes at the specified grid points. Use expansion bolts for mounting. Securely fix the suspension rods into the ceiling. Cut the rods to the required vertical height.

Step 3: Mount the Primary Tees

Attach primary tees to the suspension rods. Use brackets for this connection. Position them along the longest wall dimension. Keep them parallel to this direction. Ensure the tees are level and flat.

Step 4: Install Cross Tees

Connect cross tees between the primary tees. Use the suspension system brackets. Snap the cross tees into place. Arrange them to form a complete grid pattern. Check that the entire grid is square and level.

Reviews

There are no reviews yet.