Description

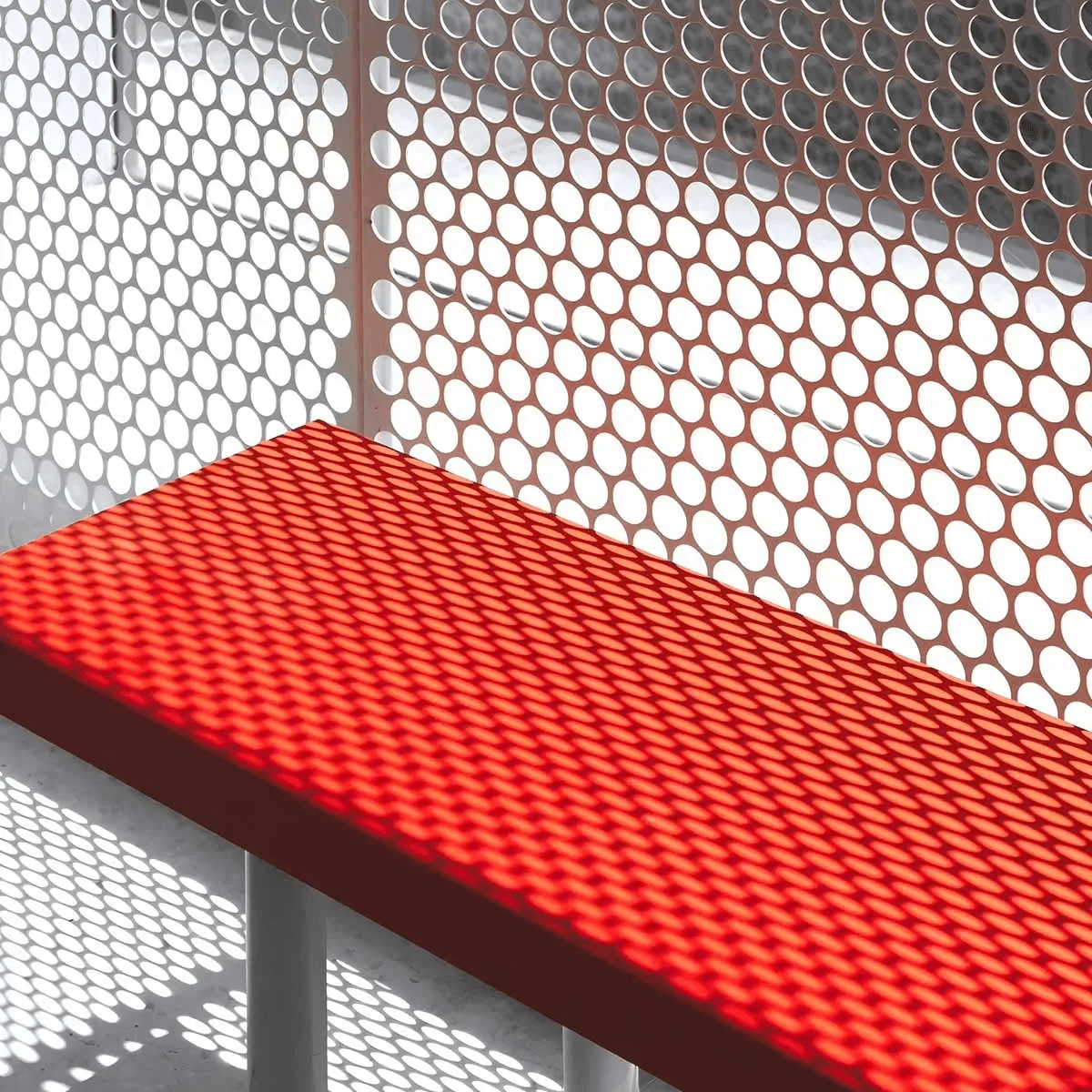

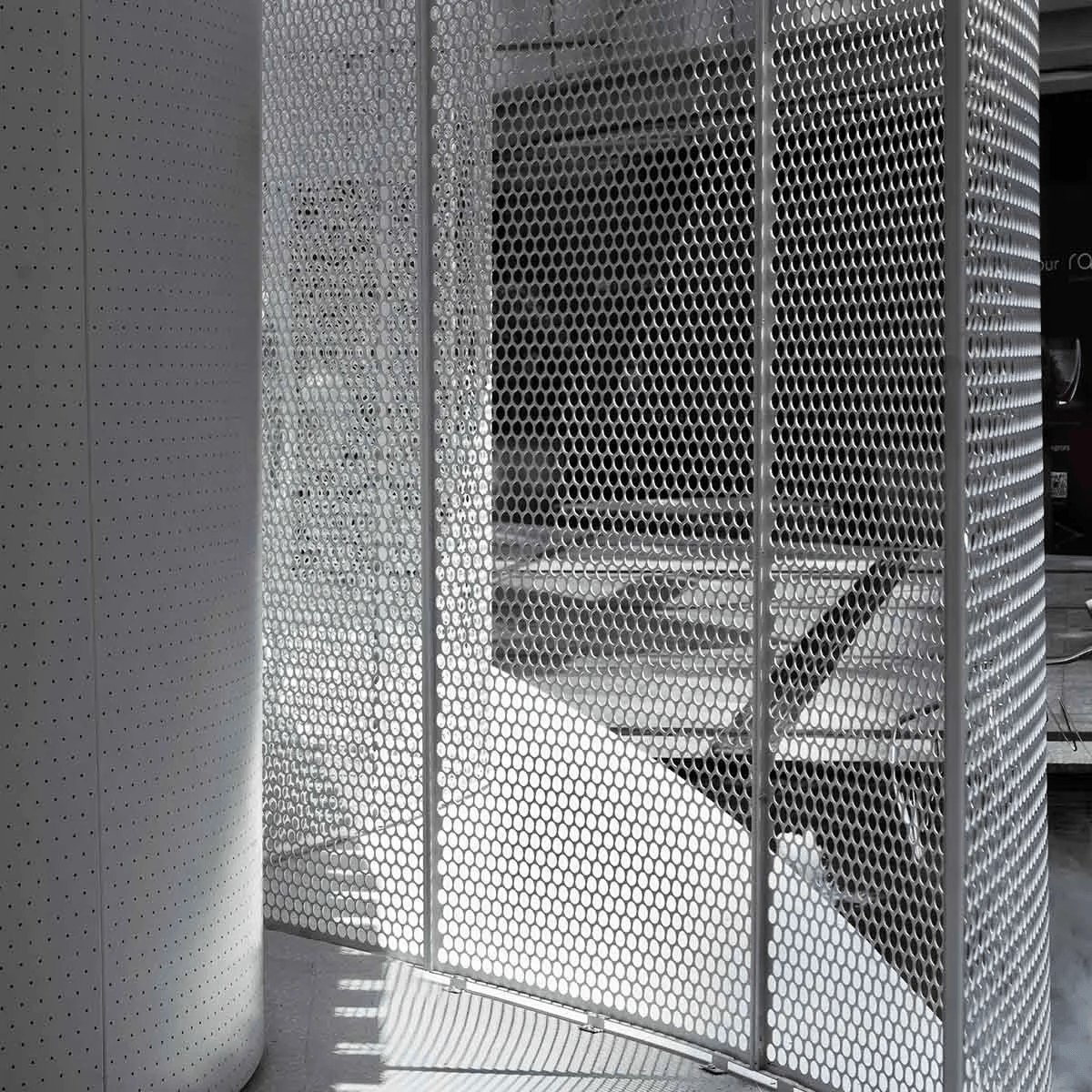

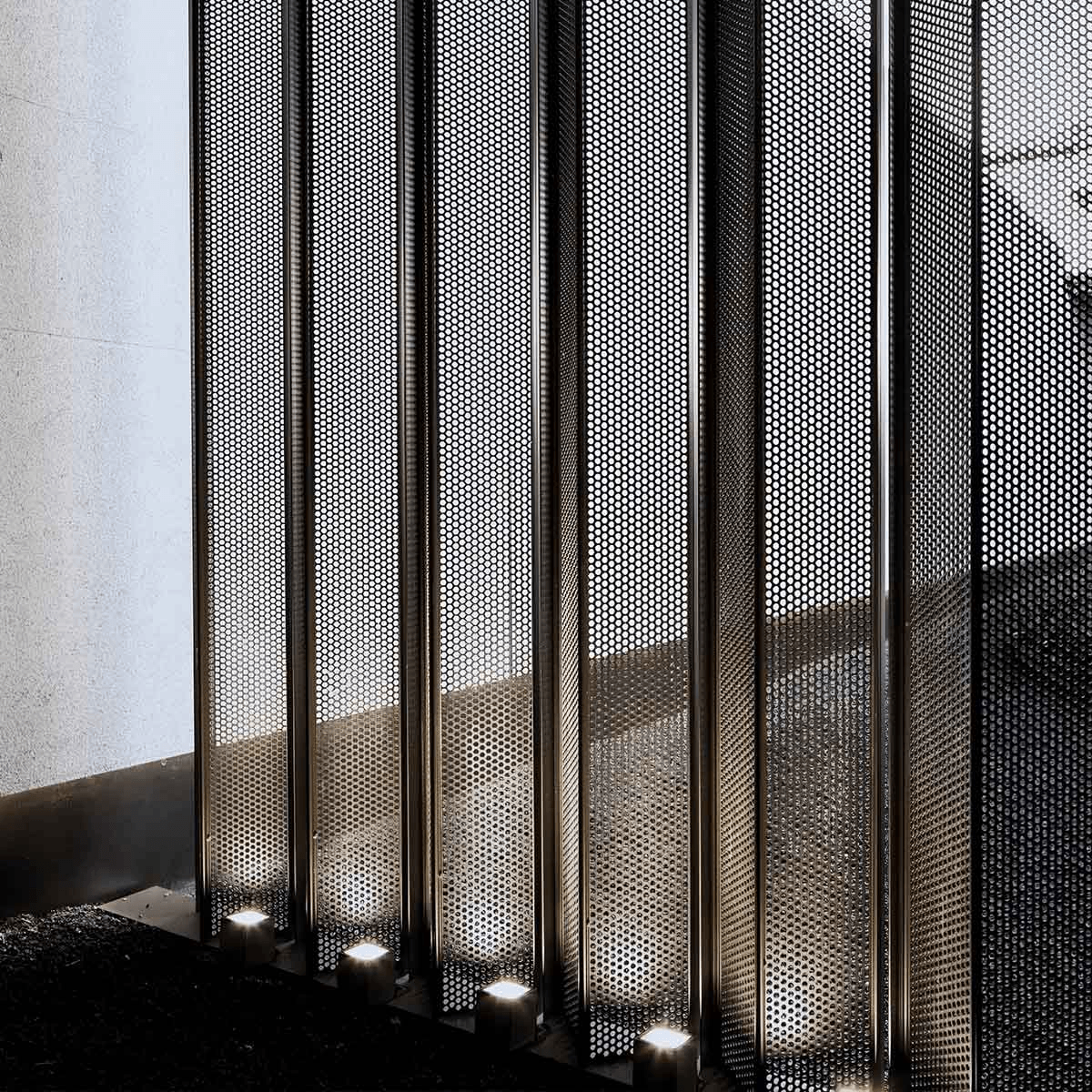

Aluminum Perforated Screen Partition Wall feature many small holes. These holes control light and heat effectively. They also provide visual improvement. The screens are both lightweight and rigid. They offer fire and environmental security reliably. This applies to both indoor and outdoor architectural applications.

Perforation Arrangements for Perforated Panel

A Wide Range of Perforated Patterns

Choosing the right perforations makes a space delightful. It improves how a room looks, feels, and sounds. Pattern choice greatly impacts appearance and functionality. Consider several key points during your selection process.

Hole Shapes

Common perforations include round and square holes. Slot shapes are also available. Clients may request custom designs. The screen design must be distinctive. The ventilation system must function properly. Your plan should satisfy both requirements.

Hole Sizes and Spacing

Hole diameter and spacing influence light transmission. They also affect air flow and noise levels. These features allow screens to meet any area’s needs. They fulfill both functional and aesthetic demands.

Custom Designs

Hole spacing and size direct sound and air movement. They also influence sunlight penetration. Various openings make screens functional and aesthetic. They perform well in any location.

Acoustic Optimization

Pattern design can improve sound quality. It controls the amount of exposed open area. Designs on acoustic panels increase sound absorption. This enhances comfort and calm in a space.

Visual Impact

Patterns create dynamic texture in interiors. They produce detailed shadow effects. Smart design changes make screens functional and attractive. This approach beautifies the screens effectively.

Material Efficiency

Optimal perforation schemes minimize material waste. They maintain strength and structural stability. This ensures the screen’s operational performance. It also supports efficient, eco-friendly design solutions.

Our Aluminum Perforated Screen panels solve aesthetic and acoustic issues. They offer unlimited design possibilities, meet basic building needs reliably. They are a savvy, practical choice for diverse architectural spaces.

Specifications

| Standard | GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN |

| Thickness | 0.8 mm – 3.0 mm | |

| Height/Width | 30 mm – 1850 mm, Customized | |

| Length | 1220 mm – 3000 mm, Customized | |

| Tolerance | ±1% | |

| Alloy Grade | 1050, 1060, 1100, 3003, 3105, 5052, etc. | |

| Technique | Cold Rolled | |

| Finish | Powder Coating, PVDF Coating | |

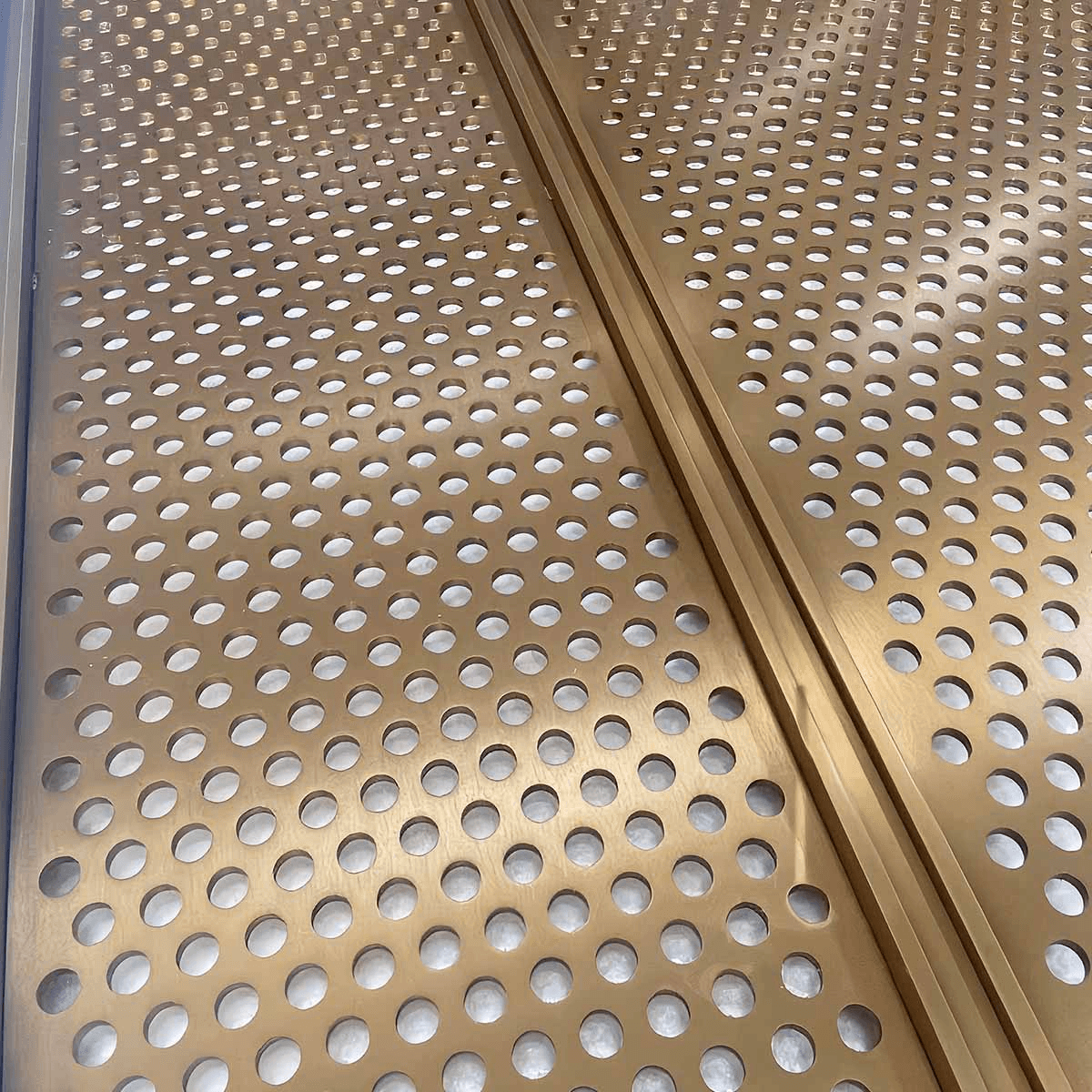

| Colors | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc. | |

| Edge | Mill, Slit | |

| Applications | Ceiling, Wall Panel, Facade, Interior Decorations | |

| Packing | PVC + Waterproof Paper + Wooden Package |

Surface Finishes for Aluminum Perforated Screen Partition Wall

A Wide Range of Color Options

Surface finishes boost durability and aesthetic value. Powder coating offers a rich color palette. Anodizing provides excellent corrosion resistance.

Powder-Coated Finish

Apply dry powder to the aluminium mesh. Heat it to form a decorative layer. This layer resists chipping and fading. It also prevents corrosion effectively. It ensures long-lasting performance and appearance.

Anodized Finish

Anodizing creates a thick oxide coating. This coating protects the aluminium mesh. It reduces corrosion and increases strength. Colors also resist fading well. This makes it a strong, beautiful architectural material.

PVDF-Coated Finish

A PVDF finish is highly durable and UV resistant. It retains color exceptionally well. This makes it ideal for exterior screens. The coating provides long-term protection. It maintains a sleek, vibrant look over time.

Choosing the right finish increases performance and aesthetics. Powder, anodized, and PVDF finishes each offer special advantages. They all provide lasting quality for architectural applications.

Processes Of Making Aluminum Perforated Screen Partition Wall

High-Precision Metal Fabrication

Manufacturers design Aluminum Perforated Screens with precise processes. These processes verify strength and consistency. They also ensure creative versatility. The work involves stamping solid metal pieces. This creates decorative or functional panels.

Applications

Creative Uses From Facades to Interiors Screen Partition Wall

Aluminum Perforated Screen Partition Walls offer durability, utility, and beauty for various environments. They add modern charm and provide practical solutions in contemporary design.

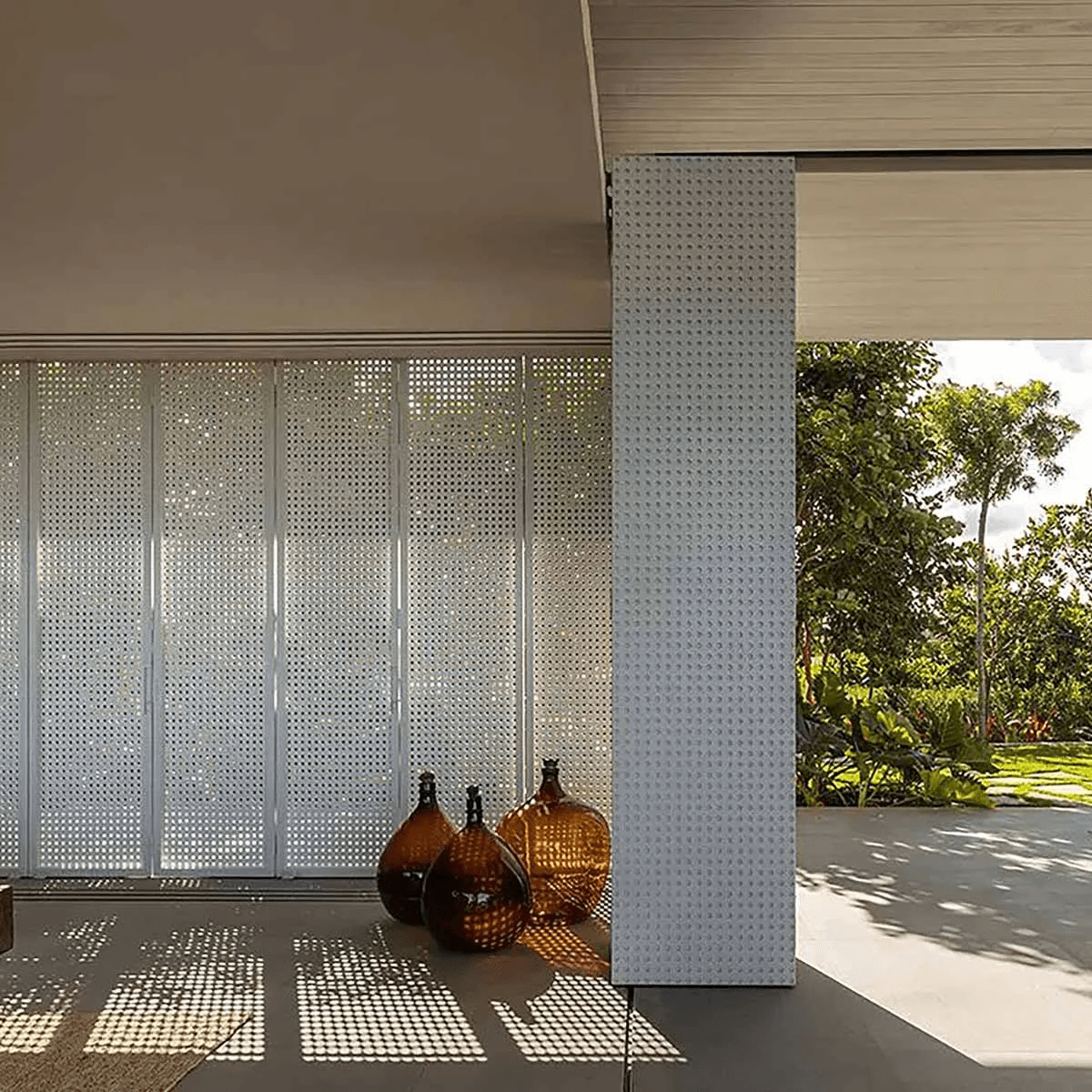

Architectural Design

Commonly used in projects, they enhance facades, sun filters, and privacy screens. These panels improve ventilation and light, creating a modern yet elegant feel.

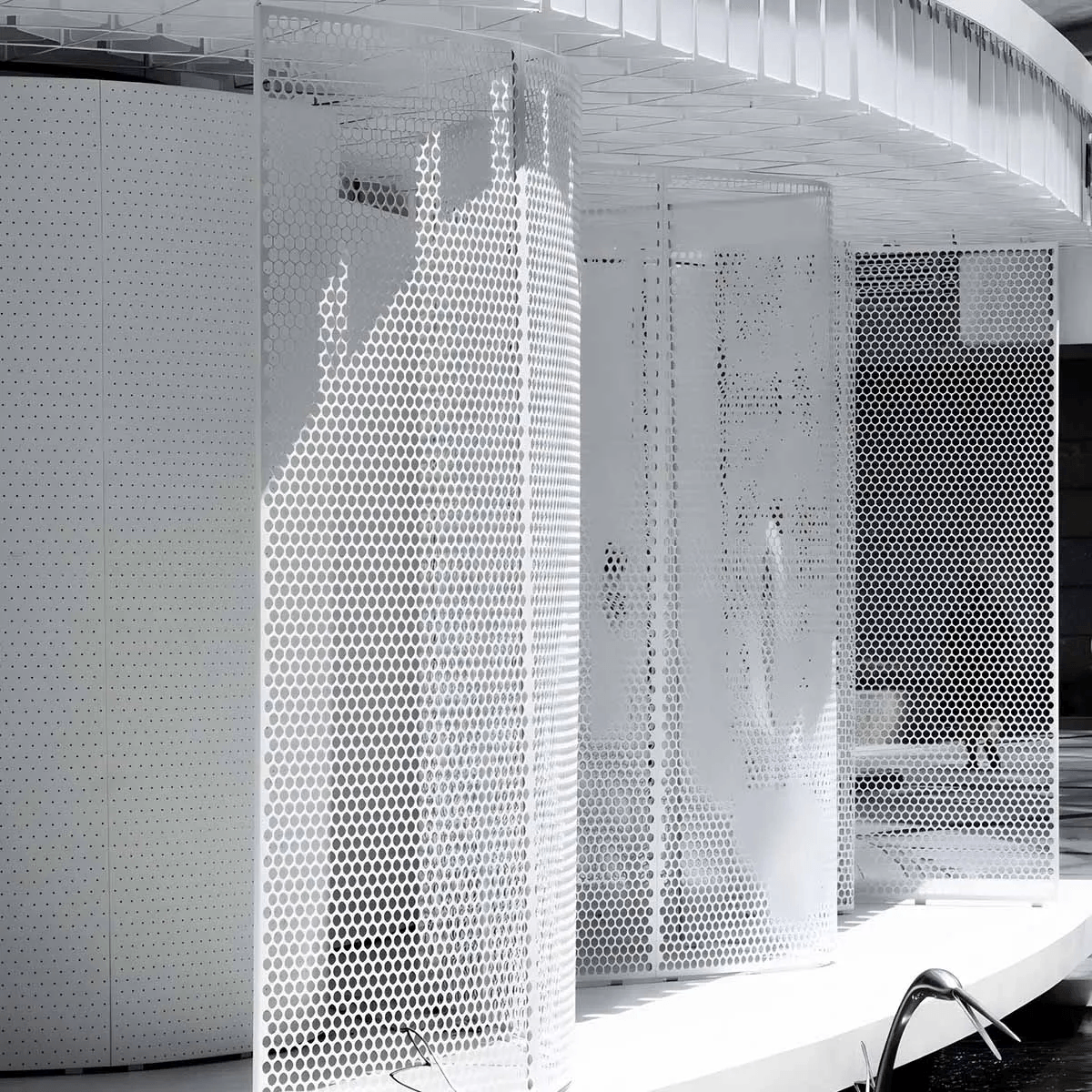

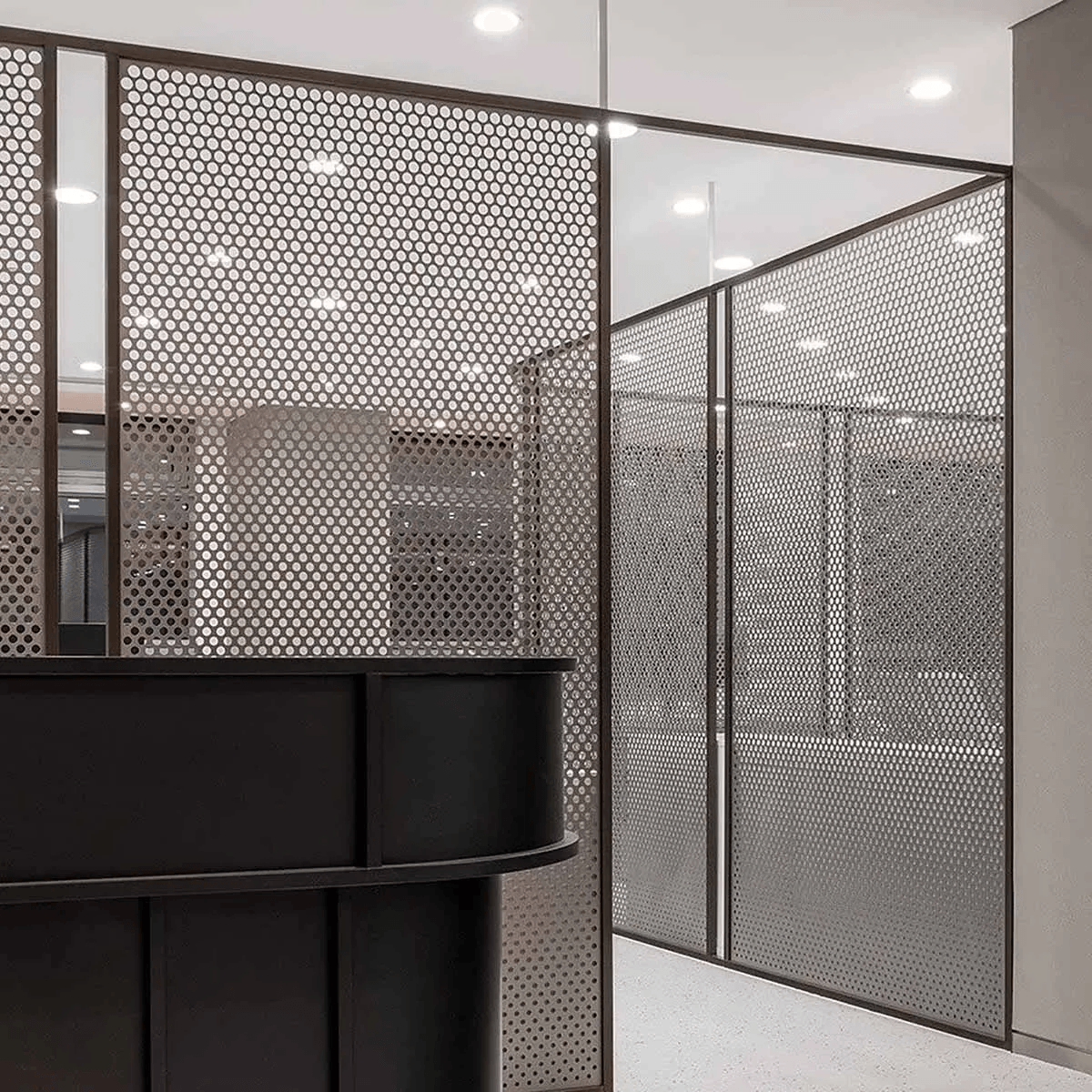

Interior Design

They serve as room dividers, decorative panels, and feature walls. They add aesthetic appeal, texture, and controlled privacy while ensuring even light dispersion.

Furniture Manufacturing

Used in tables, chairs, and cabinets, they provide a modern look. They are both functional and aesthetically appealing, enhancing ventilation in storage.

Retail Displays

Used on shelves, racks, and as dividers, they attract customer attention. They add vibrancy and maintain an open, visually friendly space.

Garden & Landscape Design

They function as contemporary fencing, arches, and privacy screens. Climbing plants can attach to them, adding style, practicality, and color to outdoor areas.

Acoustic Panels

In auditoriums and theaters, they absorb sound and reduce noise. They provide effective noise control while improving visual aesthetics.

Industrial Applications

Widely used as partitions and machine guards in factories, they allow airflow, ensure safety, maintain visibility, and support efficient operations.

Safety & Security

Used for balustrades, guardrails, and window screens, they provide protection while maintaining visibility and design integrity.

Aluminum Perforated Screen combine functionality with durability and outstanding versatility. This rare combination makes them highly demanded for increasing efficiency and beauty.

Reviews

There are no reviews yet.