Description

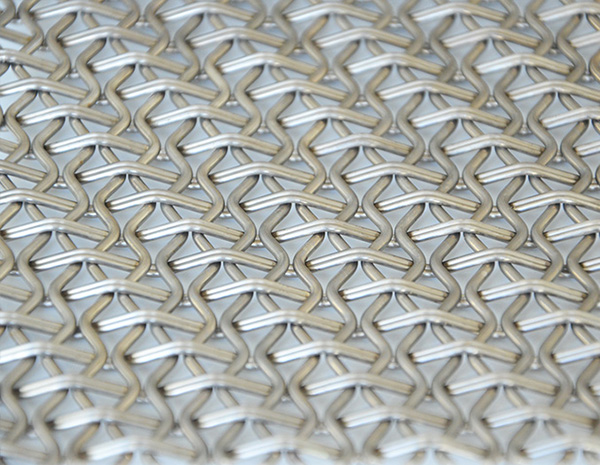

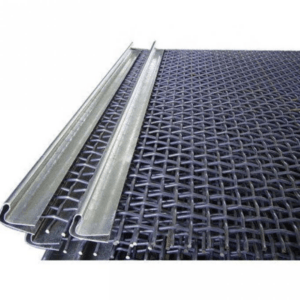

Crimped wire mesh typically refers to the pre-crimped woven variety, a product in which ABX Metal holds decades of specialized manufacturing experience. Our crimped wire mesh delivers the strength and stability required for diverse applications, including window guards, door protection, interior partitions, storage rack systems, industrial screening and sieving, security structures, and food processing facilities. We subject every product to rigorous quality verification, ensuring our complete crimped wire mesh range meets the highest standards while remaining competitively priced.

We employ precision rotary dies during the pre-crimping stage, creating a consistently strong and stable mesh structure that maintains uniform openings. To further enhance performance, we incorporate intermediate crimps between intersections, providing exceptional rigidity and durability.

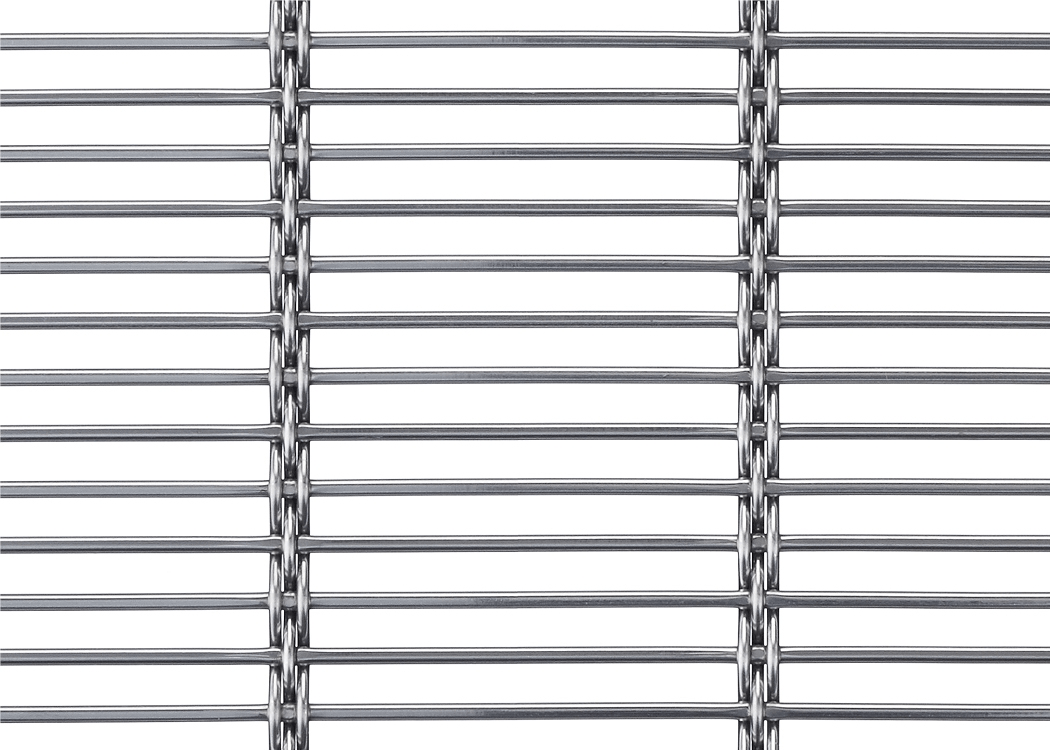

We supply crimped wire mesh in both roll and sheet formats, supported by comprehensive conversion services including precision slitting, custom cutting, electro-polishing, professional forming and welding, and specialized fabrications to meet exact project requirements.

Material Options

Customers select from multiple wire material options tailored to specific application needs:

Galvanized steel wire

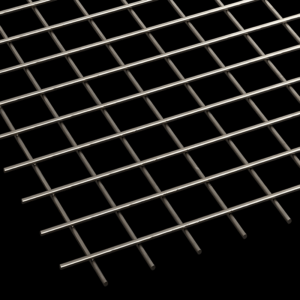

Stainless steel wire

High-tensile steel wire

45# Mn & 65# Mn black steel wire

Copper

additional non-ferrous metals

We supply crimped wire mesh in both roll and sheet formats, supported by comprehensive conversion services including precision slitting, custom cutting, electro-polishing, professional forming and welding, and specialized fabrications to meet exact project requirements.

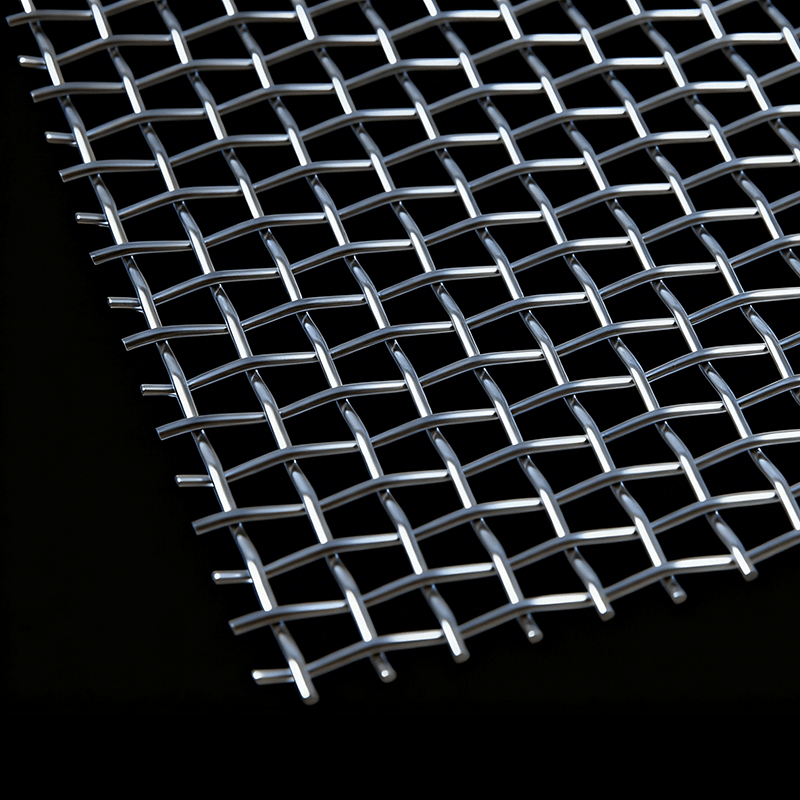

Specifications

- Wire diameter 1.0mm x mesh opening 8mm or 10mm

- Wire diameter 1.5mm x mesh opening 12.5mm, 15mm or 20mm

- Wire diameter 3mm x mesh opening 15mm, 20mm, 30mm

- Roll length & width: 1mX25m, 1mX30m, 1.2mX25m, 1.2mX30m

- Sheet sizes are customer made and we offer cut-to-size service

Applications of Crimped Wire Mesh

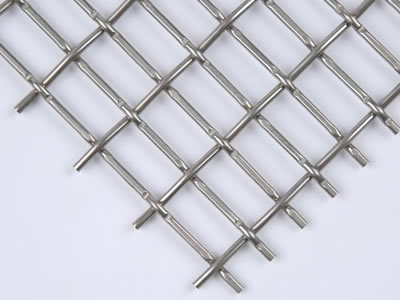

1. Screening & Sizing Applications

Crimped wire mesh serves as exceptional screening media across multiple industries. Its interlocking woven structure provides superior durability for material separation. Mining and quarrying operations rely on it for classifying aggregates and minerals. The precise openings ensure accurate particle size distribution in vibrating screens.

Agriculture utilizes crimped mesh for sorting grains and seeds. Food processing plants employ it for grading fruits and vegetables. Recycling facilities depend on its strength for separating materials. The construction industry uses it for sand screening and aggregate classification.

Chemical plants implement crimped mesh in filtration systems. Pharmaceutical companies utilize it for powder separation. Its rigid structure maintains opening stability under continuous vibration. Different wire diameters accommodate various particle sizes.

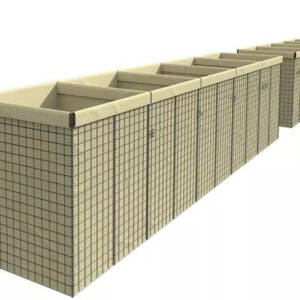

2. Separation & Protection Applications

Crimped wire mesh provides reliable security solutions worldwide. Its robust construction creates effective physical barriers. Correctional facilities install it as window guards and cell partitions. The tight weave prevents tampering while allowing airflow.

Industrial plants use it as machine guards and safety screens. The mesh protects workers from moving equipment parts. Architects specify it for balcony railings and stair guards. Schools and hospitals choose it for secure yet visible partitions.

Residential applications include security doors and window screens. The mesh deters intruders without blocking light. Animal enclosures and zoo habitats utilize its strength. Farmers install it as livestock fencing and poultry cages.

Warehouses implement crimped mesh for storage divisions. It creates secure areas while maintaining visibility. Public transportation facilities use it as platform barriers. The material withstands heavy impact and weather exposure.

Food processing areas install it as hygiene partitions. The non-porous surface meets sanitation requirements. Parking garages utilize it as ventilation covers. The open design allows air circulation while providing security.

Reviews

There are no reviews yet.