Description

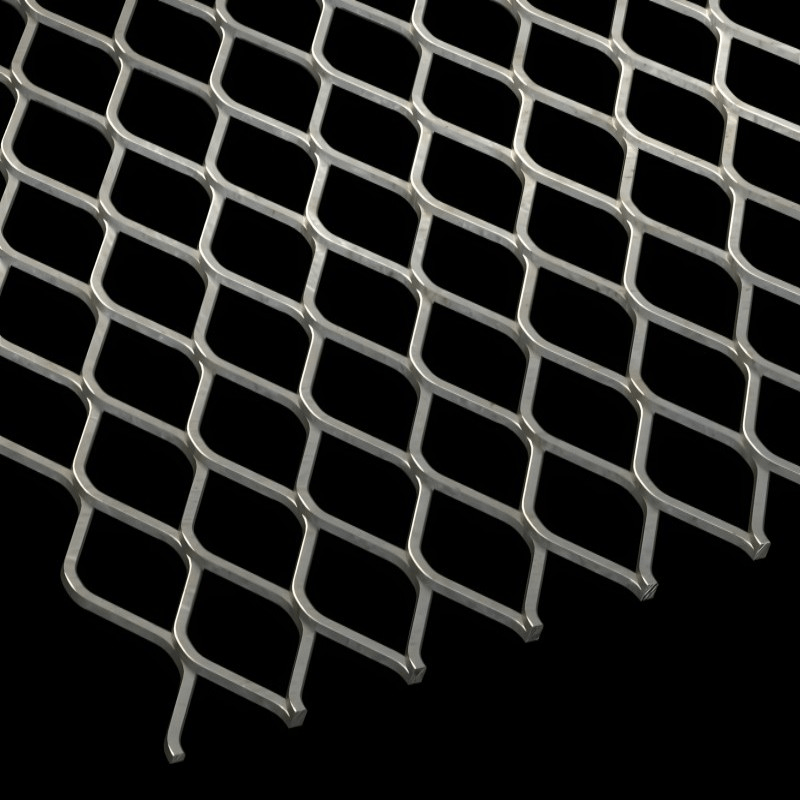

Expanded Metal Sheet Overview

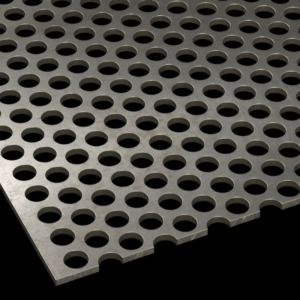

Expanded metal sheet is lightweight, durable mesh materials created by slitting and stretching solid metal sheets. They feature uniform diamond or hexagonal patterns that provide strength, ventilation, and visual texture. Available in steel, aluminum, and stainless steel, these sheets offer excellent airflow, light diffusion, and structural integrity. Commonly used in architectural facades, industrial guards, walkways, ceilings, and fencing, expanded metal combines functionality with aesthetic flexibility. Its open design reduces material use while maintaining durability, making it a versatile and sustainable choice for both decorative and practical applications.

Material Optional

Stainless Steel / Aluminum / Brass Bronze / Corten SteelApplications

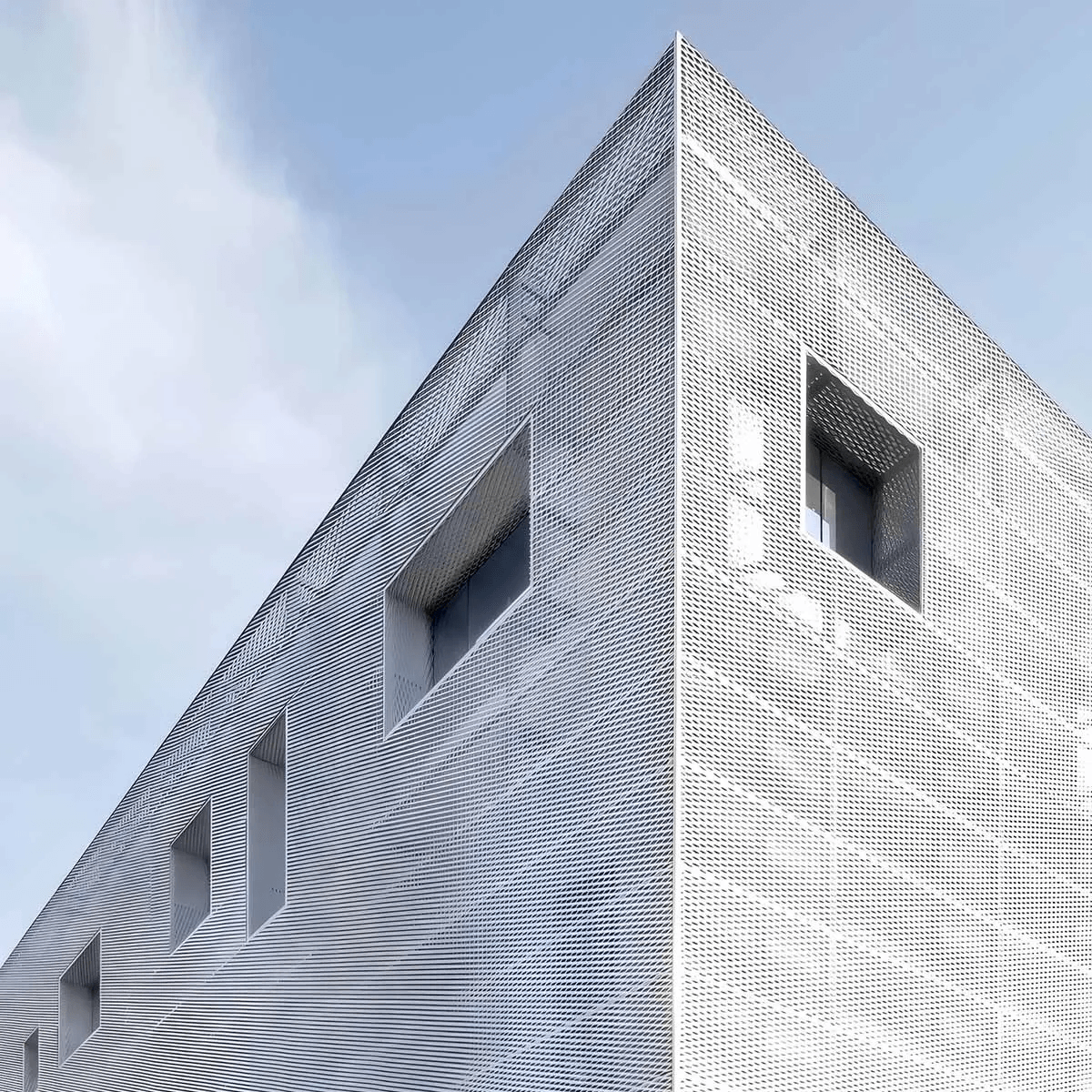

Fence / Walkway / Partition Wall / Metal Facade / CeilingsStructural steel strengthens architectural designs in facades, ceilings, and screens, providing durability, ventilation, and visual appeal. It merges modern functionality with artistic expression, allowing beauty and performance to harmonize seamlessly across diverse environments.

Elevate your architectural and interior spaces with the versatile application of expanded metal screens. From bold facades and striking ceilings to stylish partitions and privacy fences, this material blends functional efficiency with artistic beauty, meeting even the most sophisticated design requirements.

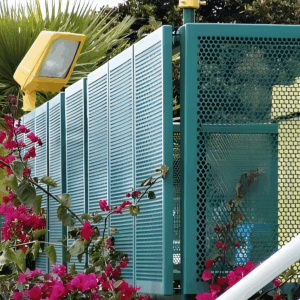

- Architectural Facades – Expanded metal facades add texture and depth while providing ventilation, light diffusion, privacy, and solar shading.

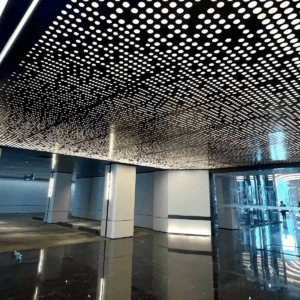

- Ceilings and Interior Panels – Expanded metal ceilings and panels offer a lightweight, eye-catching aesthetic that enhances acoustics with a sleek industrial style.

- Security Fencing and Barriers – Expanded metal screens provide strong, cut-resistant protection for fences and safety barriers, maintaining visibility in industrial settings.

- Walkways and Flooring – Expanded mesh supports platforms, catwalks, stair treads, and floor grating, handling heavy traffic with a slip-resistant surface.

- Sunshades and Louvers – Expanded mesh serves as solar shading and louvers, reducing glare and heat gain while allowing airflow for energy-efficient, modern design.

- Retail and Display Fixtures – Expanded metal mesh creates sturdy, visually open displays and fixtures, combining security with aesthetic appeal.

- Infrastructure and Transportation – Expanded mesh reinforces bridges and tunnels, ensuring ventilation and durability even in harsh environmental conditions.

Specification

| Product Name | Expanded Metal Sheet |

| Standard | GB/T 24001-2016,GB/T19001-2016,ASTM, JIS,EN |

| Thickness | 0.5 mm-10.0 mm. |

| Width | 300mm-1850mm,Customized |

| Length | 300mm-3000mm,Customized |

| Tolerance | ±1%. |

| Alloy Grade | 1050,1060,1100,3003,3105,5005,5052,6061,6063,etc. |

| Technique | Cold Rolled. |

| Finish | Powder Coating, PVDF Coating. |

| Colors | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc. |

| Edge | Mill, Slit. |

| Applications | Ceiling, Wall Panel, Facade, interior Decorations. |

| Packing | PVC + Waterproof Paper + Wooden Package. |

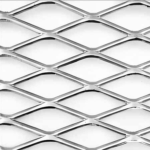

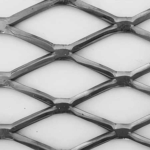

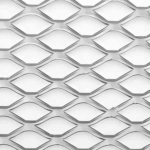

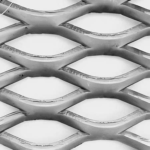

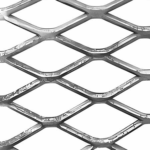

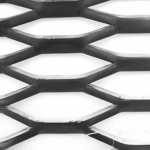

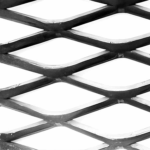

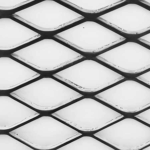

Pattern Options

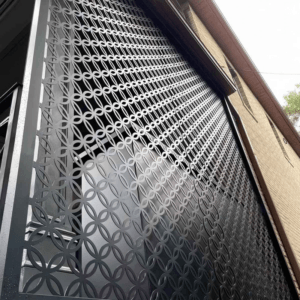

Expanded metal sheets feature diverse designs that enhance both aesthetics and functionality. The slitting and stretching process creates patterns that give architects extensive creative freedom in facade applications using metal cladding systems.

Custom Patterns Clients can incorporate brand elements, thematic designs, or project-specific motifs into custom configurations. Designers can adjust pattern size, mesh aperture, and performance parameters to meet requirements such as privacy, light diffusion, ventilation, or structural reinforcement. This approach ensures that expanded metal facades deliver both functional performance and visual elegance.

Surface Treatment Optional of Expanded Metal Sheet

ABX METAL provides metallic and solid shades. Our selection gives interiors a fresh, buoyant look. Expanded metal sheets use robust aluminum and stainless steel. They maintain excellent appearance over time. This quality suits both trendy and traditional settings effectively.

Powder-Coated Finish

Powder coating creates bright, hard-wearing surfaces. It offers numerous colors and textures. Many patterns are also available. This versatility allows wide architectural use. The finish suits traditional projects perfectly. Modern designs also benefit from it greatly.

PVDF Coated Finish

PVDF coating is highly durable and weather-resistant. It retains color excellently over years. This makes it a superior ceiling choice. It provides a sleek, long-lasting look for buildings. Its style enhances interiors and exteriors equally. Minimal upkeep is another key advantage.

Anodized Finish

Anodizing strengthens the underlying metal effectively. It also prevents oxidation reliably. This process ensures the finish lasts for years. Designers can use these durable metallic hues. They create modern or classic rooms beautifully. The shades remain vibrant long-term.

Our expanded metal sheets come in many colors and finishes. They last long and perform well in most settings. Both traditional and modern styles add visual spark. These designs are built for lasting durability. They maintain great looks with little upkeep required.

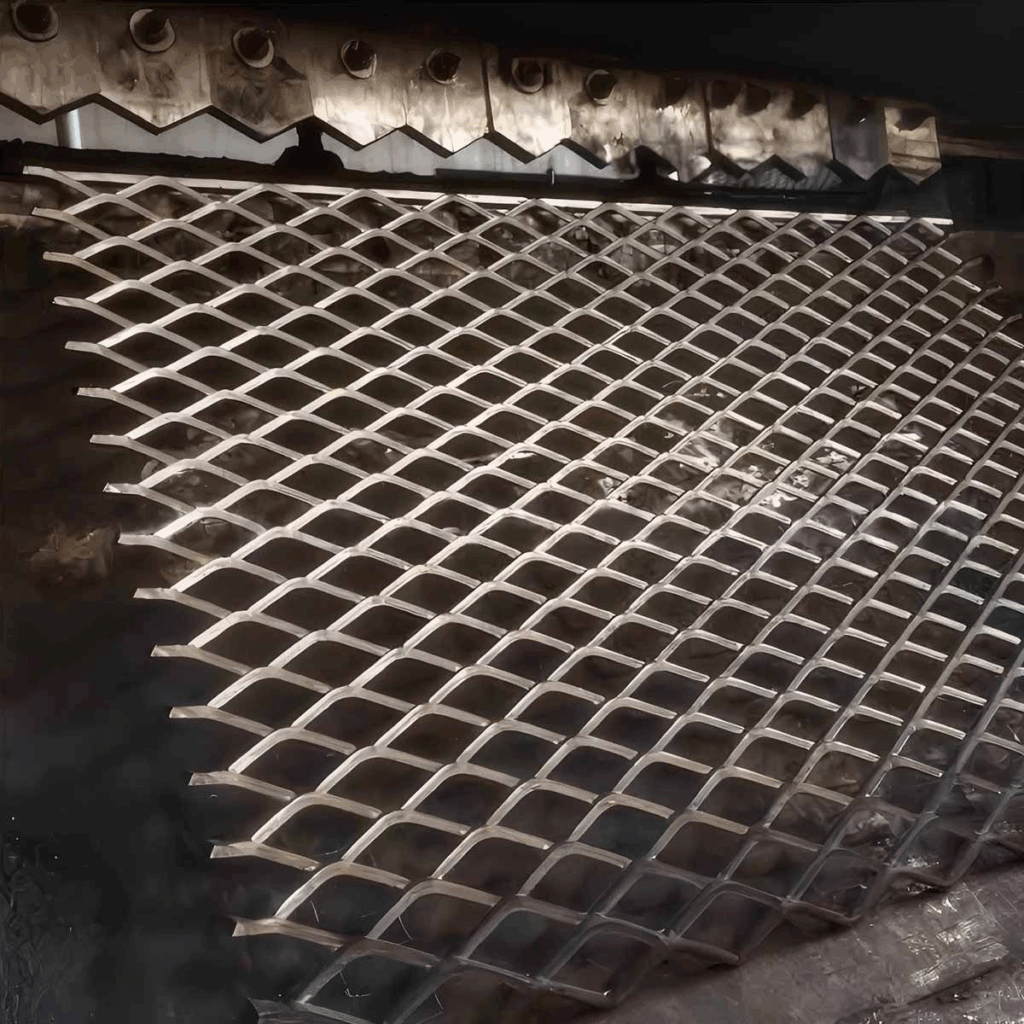

Process Of Making Expanded Metal Sheet

The expanded metal manufacturing process transforms solid metal sheets into durable mesh panels. This unique process naturally enhances material strength while creating distinctive textures. Architects specify these panels for modern facade designs worldwide.

- Sheet Selection

Manufacturers begin with premium metal sheets. They select aluminum for lightweight projects. Stainless steel suits high-corrosion environments. Galvanized steel offers economic durability. Each material serves different architectural requirements. - Slitting and Stretching

Specialized machinery simultaneously slits and stretches sheets. This process forms diamond or hexagonal patterns. It generates zero material waste. The operation creates uniform mesh structures efficiently. - Flattening (Optional)

Some projects require smooth surfaces. Electric roller systems flatten mesh strands completely. This optional process creates uniform profiles. It prepares panels for specific architectural applications. - Cutting and Shaping

Technicians cut panels to custom dimensions. They perform precise bending operations. Curving adapts panels to architectural forms. Each piece matches design specifications exactly. - Surface Treatment

Factories apply various protective finishes. Powder coating provides color options. Anodizing enhances natural metal appearance. PVDF coating ensures weather resistance. All treatments improve durability. - Installation Preparation

Manufacturers supply complete mounting systems. These include structural frameworks and connectors. The design enables quick on-site assembly. Installation requires basic tools and skills.

Aluminium VS Stainless Steel For Expanded Metal Sheet

Aluminum offers significant weight advantages. It provides excellent corrosion resistance naturally. This material allows complex forming operations. Stainless steel delivers superior strength characteristics. It withstands harsh environments effectively. Both materials suit architectural applications perfectly. Selection depends on specific project requirements.

| Feature | Aluminum | Stainless Steel |

|---|---|---|

| Weight and Handling | Lightweight, easy to transport and install. Ideal for minimal structural load. | Heavier, provides excellent rigidity and impact resistance for demanding areas. |

| Corrosion Resistance | Naturally corrosion-resistant; enhanced with anodizing or coatings. | Exceptional resistance, especially in marine-grade options like 316 stainless. |

| Aesthetic Appeal | Clean, bright look; available in various anodized or powder-coated colors. | Sleek, modern appearance with brushed or polished finishes. |

| Cost and Budget | More affordable: lower material and installation costs. | Higher upfront cost, but long-term value due to durability and low maintenance. |

| Sustainability | 100% recyclable and lightweight, reducing transportation emissions. | Fully recyclable; long lifespan supports sustainable building goals. |

Highlights Of Expanded Metal Sheet

KEY BENEFITS FOR MODERN DESIGN AND FUNCTIONALITY

Explore the forefront of architectural innovation with expanded metal sheets, where form, ventilation, and human-centric design converge. These versatile materials combine durability with refined aesthetics, contributing timeless elegance to contemporary architecture.

Structural Versatility

Expanded metal offers architects and designers exceptional flexibility in shaping complex structures and detailed surfaces. Its adaptable nature supports creative expression while maintaining structural integrity.

Enhanced Ventilation

The open patterns of expanded metal sheets promote natural airflow, making them ideal for facades, ceilings, and screening systems. This design feature fosters well-ventilated and comfortable environments.

Durability in Design

Fabricated from stainless steel or aluminum, expanded metal mesh delivers lasting resilience and low maintenance, ensuring reliable performance across diverse architectural applications.

Aesthetic Appeal

With its distinctive texture and modern appearance, expanded metal enhances both exterior facades and interior spaces, adding visual character and a refined aesthetic to any project.

Lightweight Construction

Aluminum expanded metal achieves an optimal balance of strength and low weight, reducing structural load without compromising durability—ideal for applications where weight efficiency is essential.

Reviews

There are no reviews yet.