Description

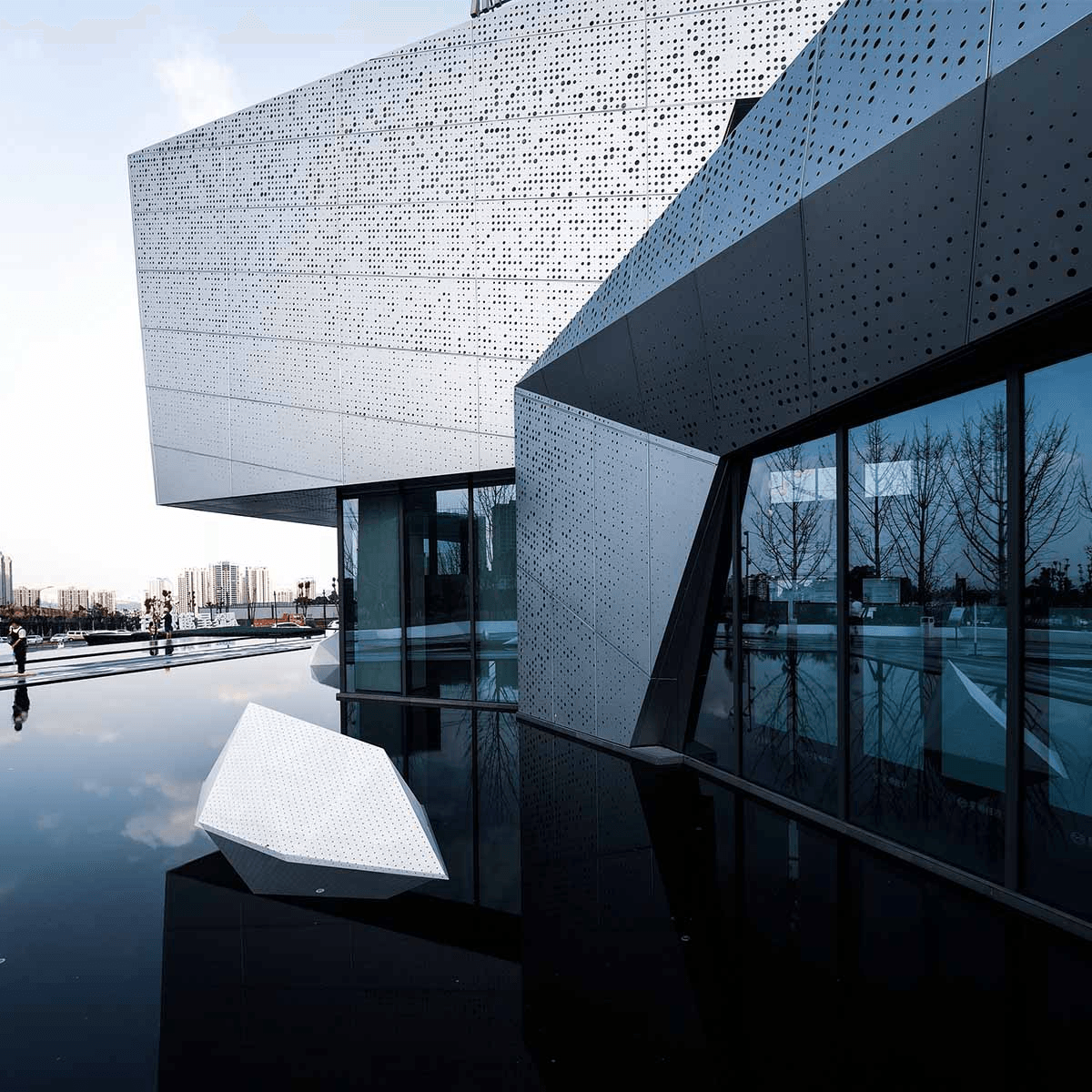

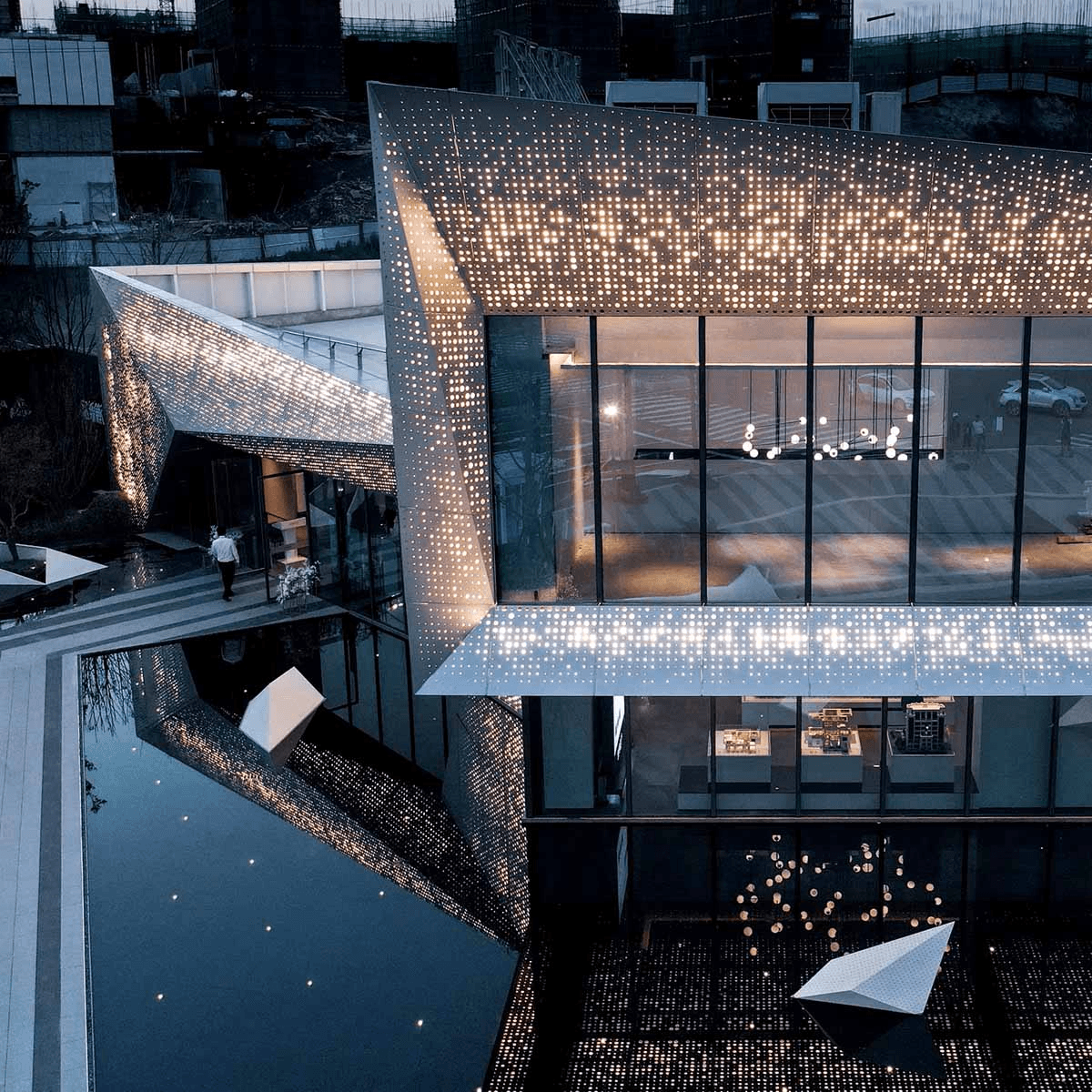

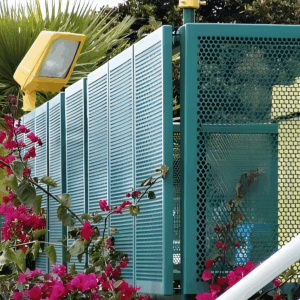

Aluminum Perforated Metal Curtain Wall panels offer aesthetic value. They also provide sustainability benefits. These curtain wall panels allow for horizontal or vertical placement. Architects use them for privacy control. They offer excellent weather protection. Their perforations maintain functional performance. The curtain wall panels remain strong and structurally stable.

Pattern Options for Perforated Metal Panels

A Wide Range of Perforated Patterns

Perforated metal panels offer a wide variety of patterns. They help architectural projects balance function and aesthetics. Choose from simple geometric shapes or complex custom designs. Custom perforated aluminum panels suit all architectural and interior applications. Explore our pattern inspiration gallery for more ideas. Find the best perforation style for your design there.

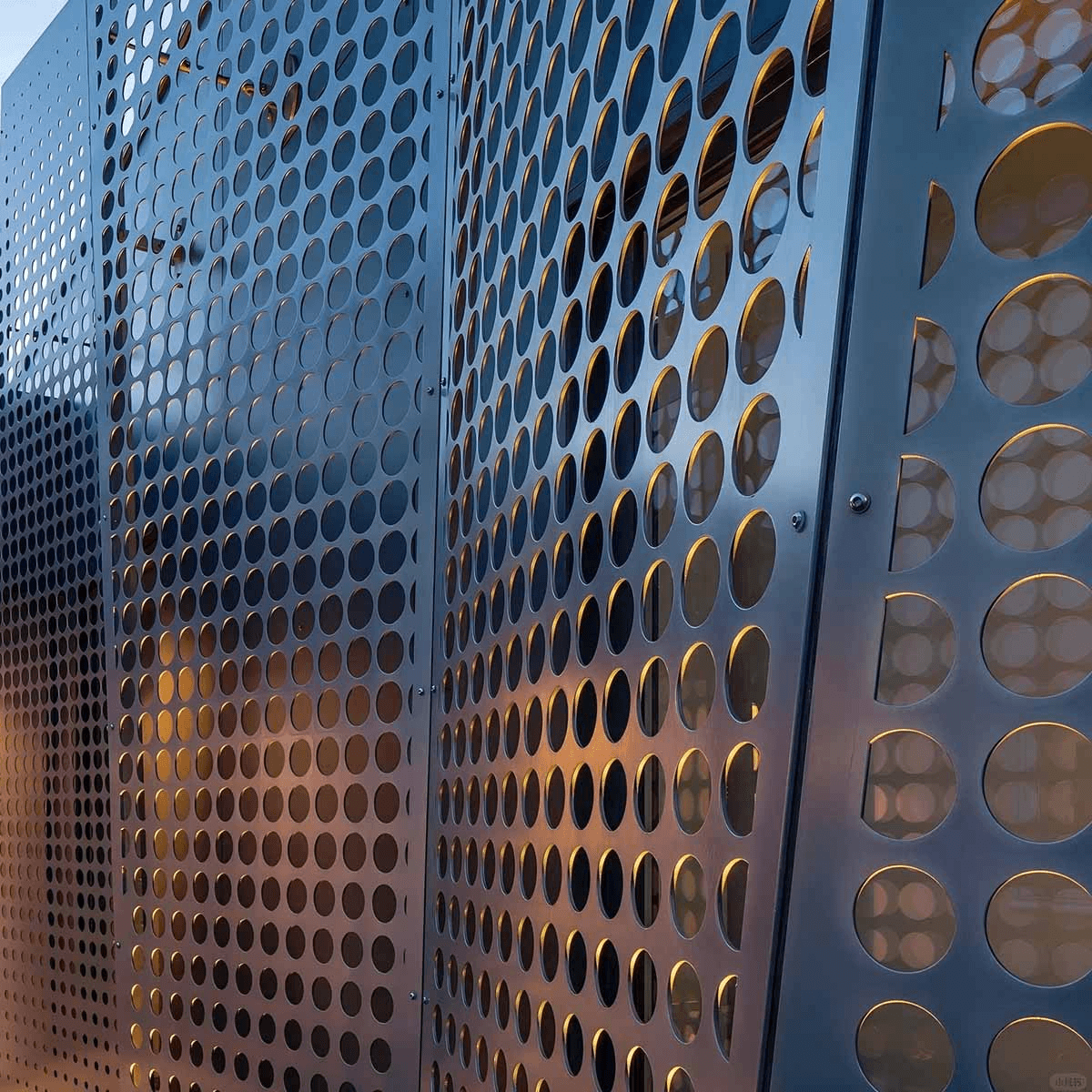

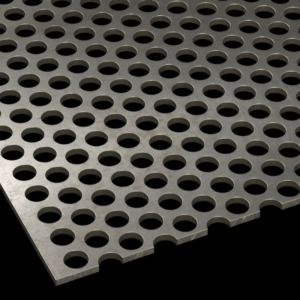

Standard Hole Patterns

Standard patterns include round, square, and slotted holes. They serve ventilation, filtration, and decorative purposes. Round holes provide balanced material strength. Square and slotted holes create a modern design aesthetic. They also offer diversified ventilation options.

Staggered vs. Straight-Line Patterns

The hole layout significantly impacts aluminum panel performance. Staggered patterns provide equal strength and airflow. This suits industrial applications well. Straight-line patterns offer a clean, uniform appearance. This style excels in modern interior design.

Variable Hole Sizes and Spacing

Adjusting hole size and spacing changes the perforated panel’s properties. It influences transparency, airflow, and light diffusion. Smaller holes create a fine, subtle texture. Larger holes allow for greater visibility and ventilation.

Custom and Decorative Patterns

Custom designs can feature unique shapes or brand logos. They create distinctive motifs for ornate visual appeal. Honeycomb, floral, and wave patterns are popular choices. These enhance facades, ceilings, and partitions. They combine functionality with artistic design.

Perforated aluminum panels enable endless design possibilities. They blend functionality with beauty across many patterns. Their flexibility supports ventilation, privacy, and style needs. This makes them suitable for countless design and interior uses.

Specifications

| Standard | GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN |

| Thickness | 0.8 mm – 3.0 mm | |

| Height/Width | 30 mm – 1850 mm, Customized | |

| Length | 1220 mm – 3000 mm, Customized | |

| Tolerance | ±1% | |

| Alloy Grade | 1050, 1060, 1100, 3003, 3105, 5052, etc. | |

| Technique | Cold Rolled | |

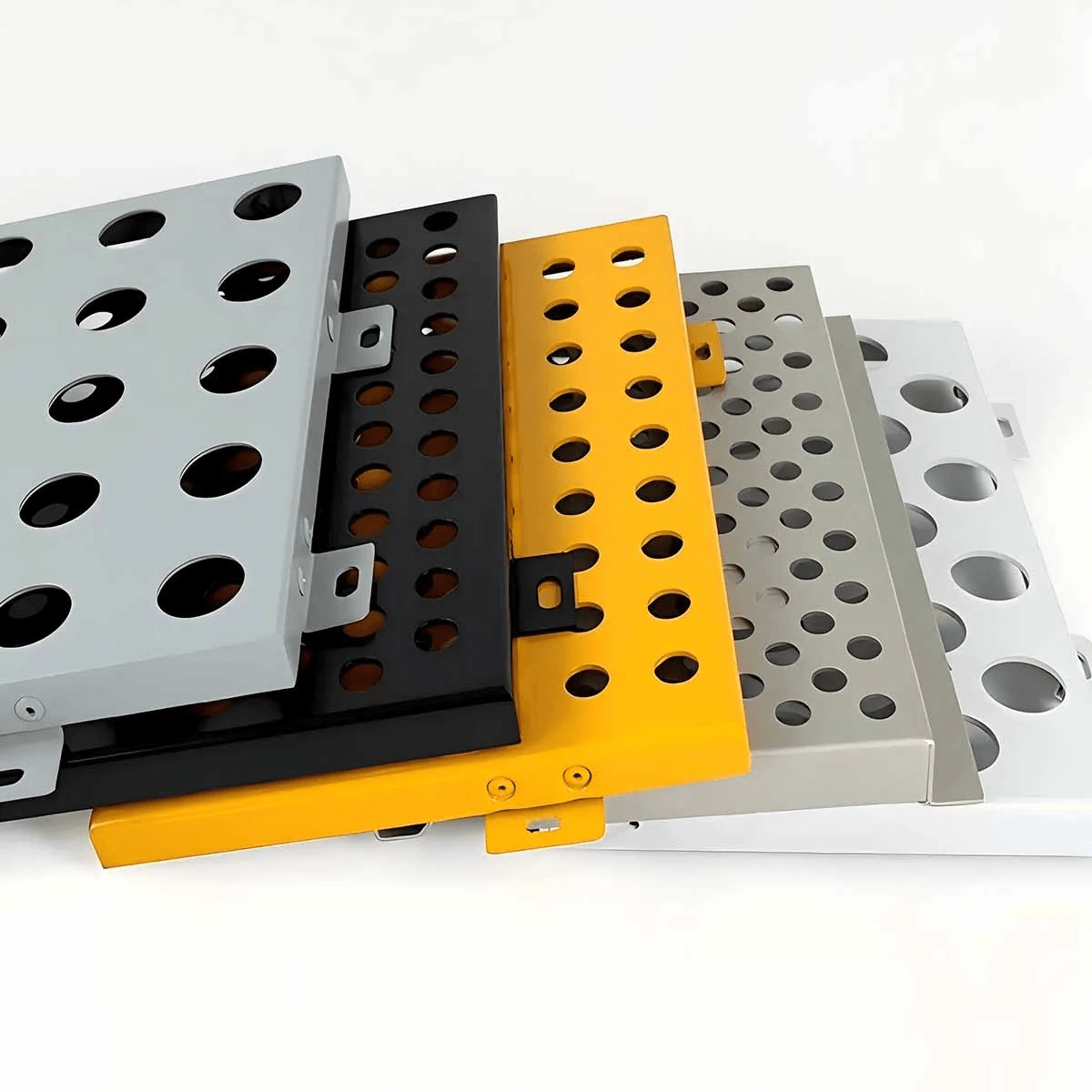

| Finish | Powder Coating, PVDF Coating | |

| Colors | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc. | |

| Edge | Mill, Slit | |

| Applications | Ceiling, Wall Panel, Facade, Interior Decorations | |

| Packing | PVC + Waterproof Paper + Wooden Package |

Finish Options for Aluminium Perforated Metal Curtain Wall

A Wide Range of Color Options

Aluminum Perforated Metal Curtain Wall accept various surface treatments. These finishes enhance performance, aesthetics, and weather tightness. The coatings safeguard the underlying material effectively. They also unlock creative opportunities for architectural design.

Powder Coating

Powder coating delivers durable, corrosion-resistant finishes. It offers numerous colors and textures. This treatment extends the facade’s service life significantly. It provides strong UV protection. It also improves resistance to normal weathering.

Anodizing

Anodizing creates a protective oxide layer on aluminium. This layer resists corrosion and abrasion effectively. The finish harmonizes with natural metallic tones. It also accommodates colored coatings. The result is an ultra-contemporary, elegant look.

PVDF Coating

Polyvinylidene fluoride (PVDF) coating offers excellent weatherability. This makes it ideal for outdoor applications. It ensures long-lasting color retention. The coating resists chemicals, pollutants, and moisture reliably.

Brushed & Polished Finishes

A brushed finish delivers a subtle, textured look. It minimizes surface glare effectively. A polished finish creates a high-gloss, reflective surface. Both options provide a sophisticated appearance. They suit various architectural designs perfectly.

Wood Grain & Custom Textures

Advanced treatments can emulate wood or stone. They use specialized sublimation techniques. These finishes replicate natural textures convincingly. They retain aluminium’s lightweight and durable properties.

Surface finishes boost both durability and aesthetics. They enable beautiful architectural designs. Their lasting characteristics support diverse textures and colors. This versatility suits modern engineering applications perfectly.

Processes of Making Perforated Metal Curtain Wall

High-Precision Metal Fabrication

These perforated metal panels offer flexibility and strong aesthetic value. Their suitability makes them popular in contemporary architecture. Precision manufacturing brings intricate designs to life. This capability defines modern perforated metal curtain wall.

Design and Conceptualization

The process begins with careful planning. Consider the panel’s shape, style, and dimensions. Key factors include hole pattern, panel size, and construction purpose. This ensures successful architectural integration.

Material Selection

Material choice is crucial for perforated curtain wall. Options include copper, aluminum, and stainless steel. Each metal offers specific benefits. These may include durability, corrosion resistance, or a modern appearance.

Perforation Process

Manufacturers create panels using precise piercing methods. CNC punching machines ensure hole accuracy. Laser cutters guarantee consistency across the entire surface.

Finishing and Surface Treatment

Apply finishes after perforation to enhance the perforated panels. Processes like powder coating improve durability. Anodizing or painting increases weather resistance. These treatments also offer limitless color choices.

Panel Formation

Shape the perforated panels to meet architectural needs. Techniques include bending, curving, and rolling. These methods achieve the desired contours. They adapt perfectly to each project’s design.

Quality Control

Rigorous checks ensure every perforated panel meets high standards. Inspectors verify structure, hole alignment, and dimensions. They also assess the surface finish. Only approved panels proceed to the next stage.

Installation Considerations

Manufacturers provide solutions for efficient installation. This includes custom attachment systems and clear instructions. On-site support ensures a smooth process. It guarantees proper integration with the building facade.

More Applications

Perforated Curtain Wall Panels enhance contemporary aesthetics by fusing function with form. Their precise patterns improve ventilation, sunlight control, and privacy, making them ideal for modern, performance-driven buildings.

Building Facades

These panels make facades more attractive and functional, optimizing natural light, improving air circulation, and helping regulate temperature through distinctive artistic textures.

Sunshades and Screens

In sunny climates, they serve as excellent sunshades and screens. Their multiple apertures disperse sunlight, reducing heat and glare while maintaining clear visibility.

Privacy Screens

Ideal for balconies, patios, and interior dividers, their apertures balance seclusion with openness, allowing light, ventilation, and framed views.

Art Installations

The variety of designs makes them perfect for public art, museums, and galleries, where their complex arrangements function as captivating artworks.

Acoustic Panels

Suitable for theaters, auditoriums, and conference rooms, perforations with acoustic backing absorb sound, reducing noise and enhancing auditory comfort.

Signage and Wayfinding

They provide an uncluttered surface for signage in commercial buildings, where strategic apertures improve both visual appeal and functionality.

Landscape Design

In landscapes, they create stunning trellises, fencing, and screens, balancing practical use with sophisticated elegance.

Energy Efficiency

Their integration supports sustainable architecture by optimizing sunlight penetration, contributing to overall energy efficiency.

Brand Identity

Businesses can use them as striking surfaces for logos and custom elements, strengthening brand recognition.

Architects achieve harmony with these panels, which combine form, function, and sustainability. The material offers flexibility for diverse projects and inspires creative design expression.

Reviews

There are no reviews yet.