Description

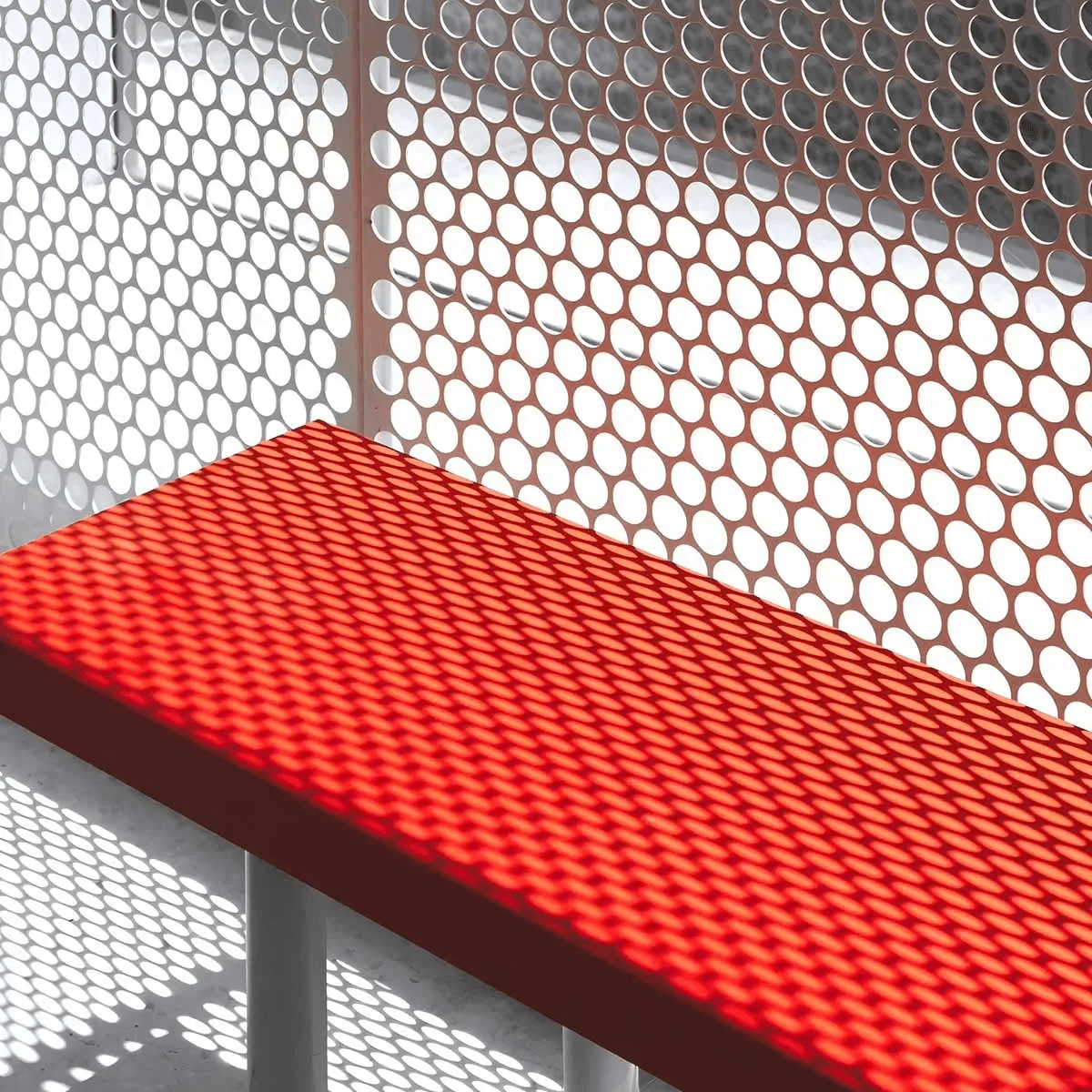

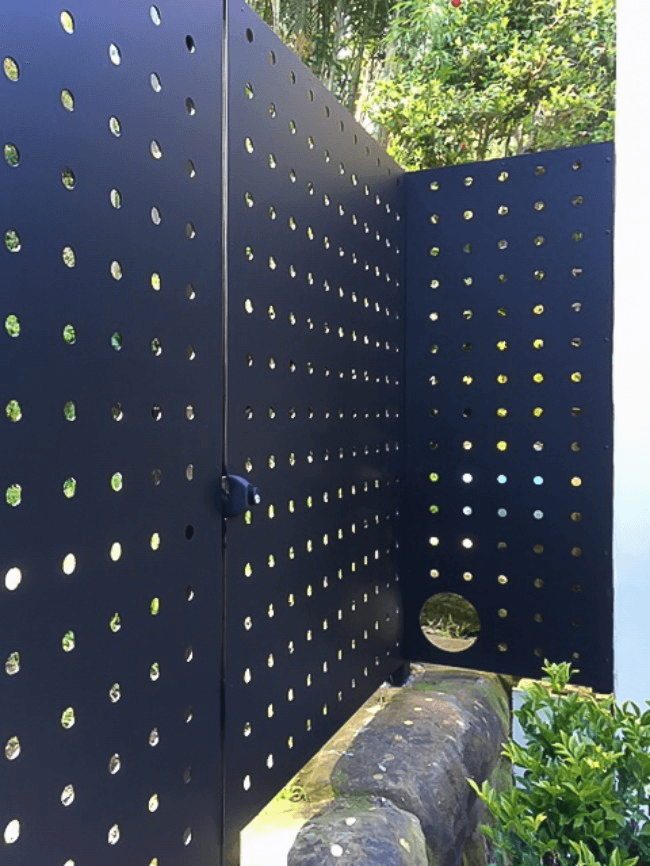

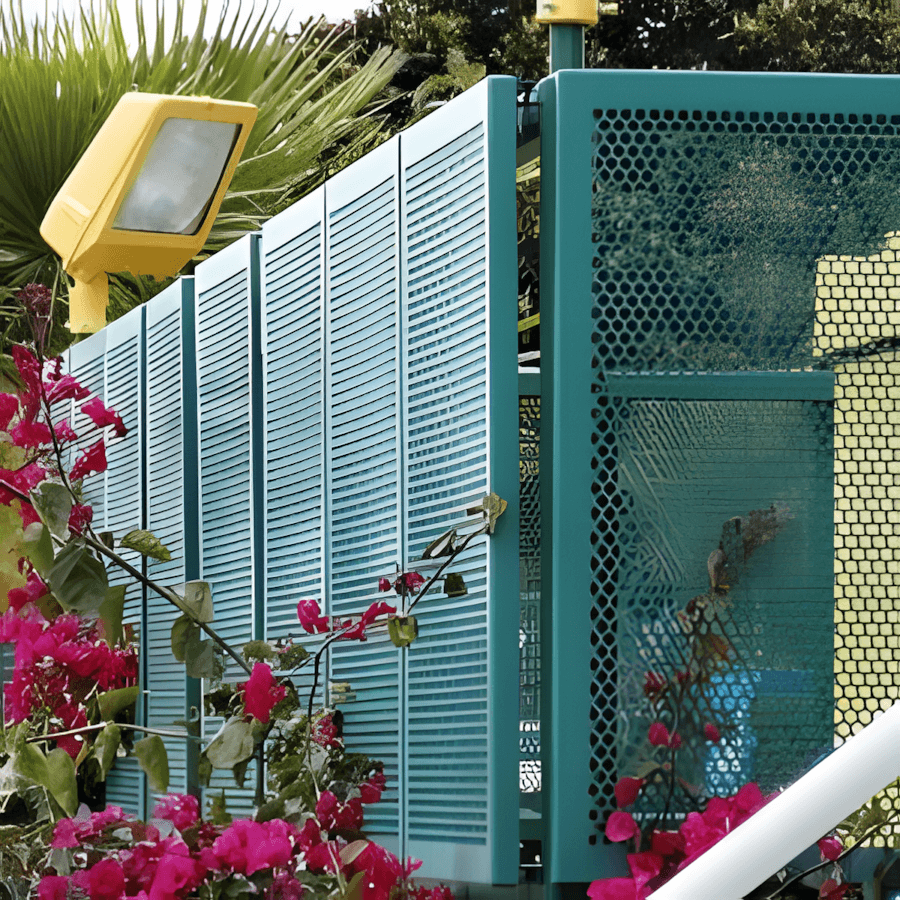

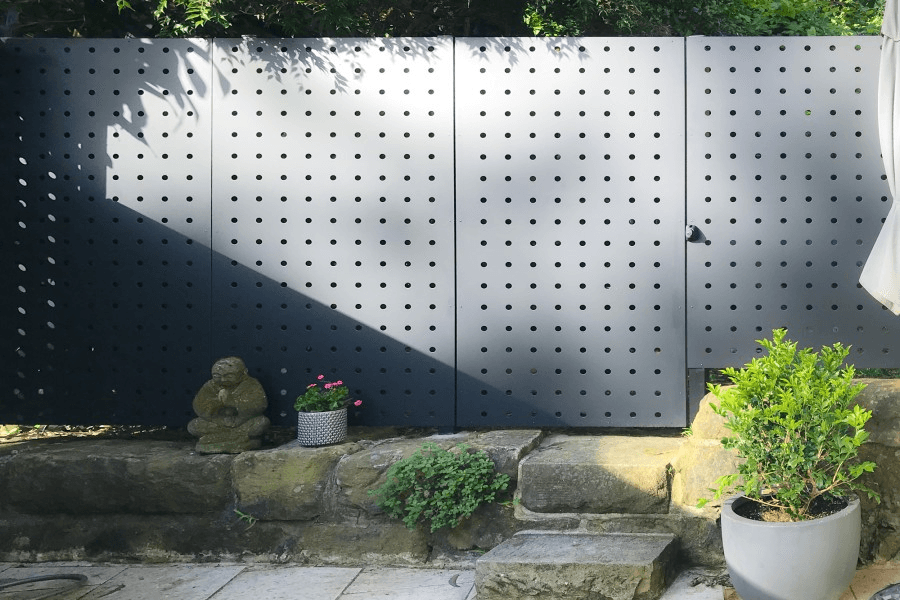

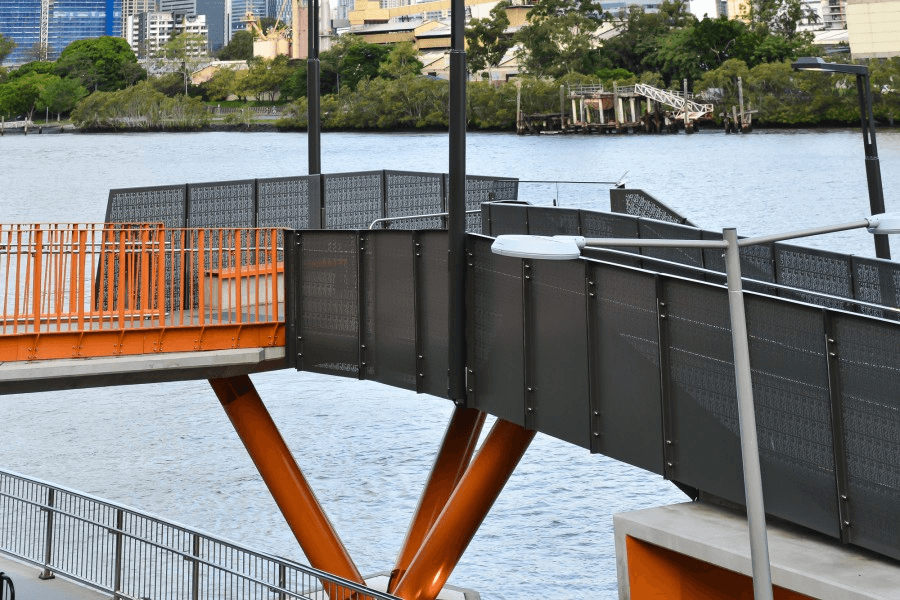

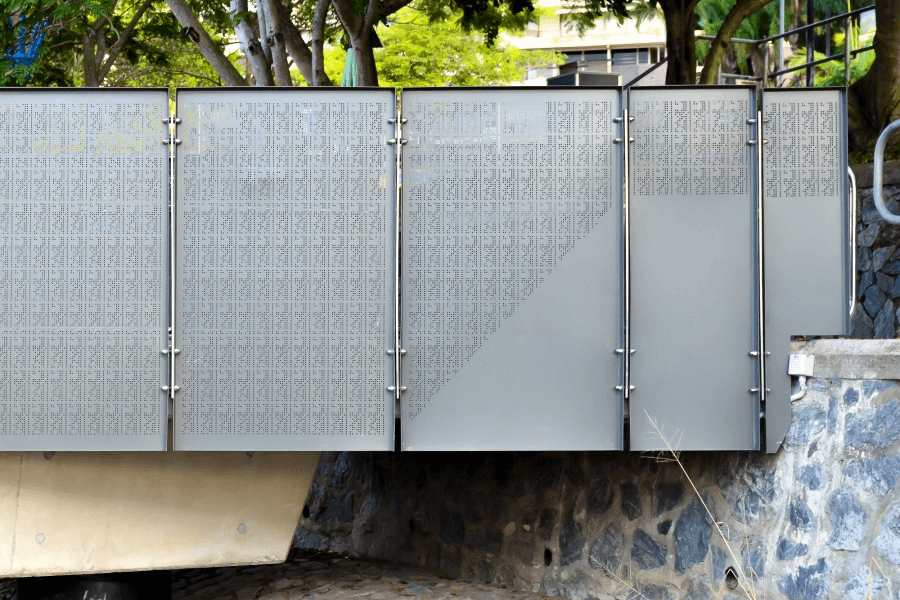

Perforated metal privacy fence offer a modern outlook. They are eye-catching items for landscape designers. These fences achieve perfect cohesion of form and function. Their minimalist vibe features modern lines and patterns. This creates a timeless appeal for outdoor areas.

Pattern Options

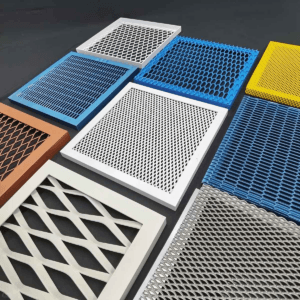

Perforated metal panels offer extensive pattern versatility for privacy fence. They balance functional performance with visual aesthetics perfectly. You can select simple geometric shapes. Intricate custom designs are also available. We offer tailored panel solutions. They suit all architectural and interior applications. Explore endless possibilities in our inspiration gallery. Find your ideal perforation style there. It will elevate your design vision.

Hole Shapes

The most common perforations are round, square, or slotted. Clients also often prefer custom designs. The fence must feature a special style. The ventilation must function effectively. The design plan should achieve both goals.

Hole Sizes and Spacing

Hole diameter and spacing influence light, air, and noise. These specific features allow perforated fences to meet any area’s needs. They satisfy both functional and ornamental requirements.

Custom Designs

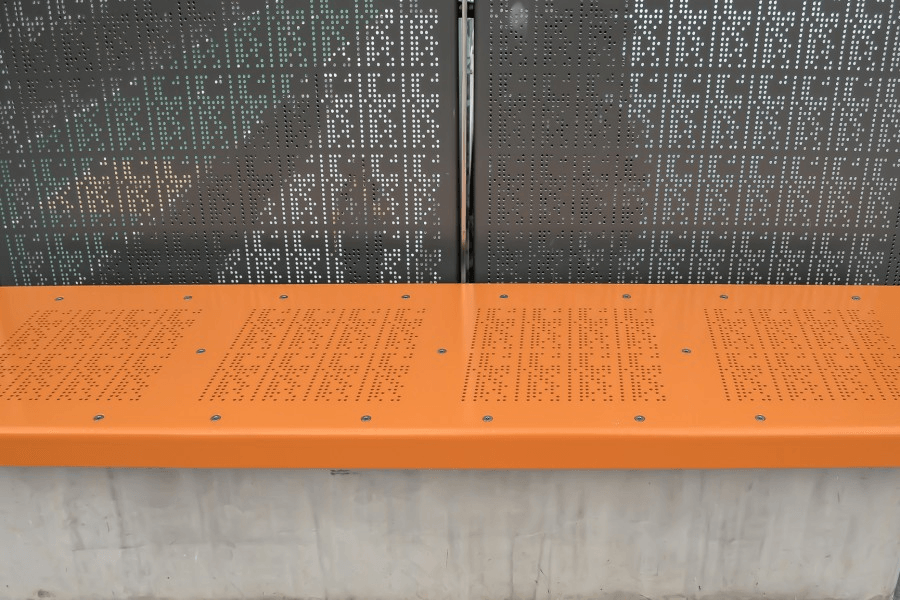

Hole spacing and diameter determine sound direction. They also control air movement and sunlight. Various openings allow fences to work anywhere. They perform well both practically and aesthetically.

Acoustic Optimization

Pattern design can assist sound quality. It allows adjustment of the exposed open area size. The primary purpose is to increase sound absorption. This enhances comfort and quietness in a space.

Visual Impact

Patterns create dynamic texture in interiors. They also produce detailed shadow effects. Smart design changes make fences functional and attractive. This approach effectively beautifies the fences.

Material Efficiency

Ideal hole distribution minimizes material waste. It maintains acceptable material strength. This ensures the structural performance of the fence. It also supports the creation of efficient, green design solutions.

Specifications

| Standard | GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN |

| Thickness | 0.5 mm – 10.0 mm | |

| Height/Width | 300 mm – 1850 mm, Customized | |

| Length | 300 mm – 3000 mm, Customized | |

| Tolerance | ±1% | |

| Materials | Galvanized Steel, Stainless Steel, Aluminum, Corten Steel | |

| Technique | Cold Rolled | |

| Finish | Powder Coating, PVDF Coating, Galvanizing, Anodized Finish | |

| Colors | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc. | |

| Edge | Mill, Slit | |

| Applications | Ceiling, Wall Panel, Facade, Fence, Screen, Interior Decorations | |

| Packing | PVC + Waterproof Paper + Wooden Package |

Surface Finishes for Perforated Metal Privacy Fence Panels

A Wide Range of Color Options

We offer numerous surface finishes for these perforated metal privacy fence panels. Each finish enhances durable beauty specifically. Options include protective powder coating. Luxurious anodizing is another choice. Attention-grabbing PVD finishes also provide architectural enhancement.

Powder-Coated Finish

Powder coating spruces up perforated metal panels. It significantly increases their durability. It also makes them look eye-catching. This finish enhances aesthetic beauty effectively. It provides high corrosion and abrasion resistance. It is also fire resistant, and comes in different colors and textures.

Anodized Finish

Anodizing creates a smooth, hard finish. This protective layer is highly durable. It resists scratches and corrosion effectively. The process increases beauty and durability. It protects against weathering and UV rays. It also resists everyday wear and tear.

PVDF-Coated Finish

PVDF coating provides a striking metallic finish. It enhances both the appearance and texture of the panel. This coating offers excellent scratch resistance. It also resists abrasion and erosion reliably. This ensures long-term architectural luster.

We offer powder coating, anodizing, and PVD coating. These finishes make panels more decorative and useful. They greatly increase aesthetic quality. They also enhance overall durability. This is crucial for long-term architectural integration.

Processes of Making Perforated Metal Privacy Fence

High-Precision Metal Fabrication

Perforated metal privacy fence panels require exact, sophisticated procedures. These procedures confirm their robustness and uniformity. They also support creative adaptability. The process involves stamping solid metal chunks. This forms decorative or functional panels. The panels feature various shapes and precise hole details.

Material Selection

The process begins with proper material choice. Commonly used materials include aluminum and stainless steel. Galvanized steel and copper are also options. These materials differ in strength and corrosion resistance. Each offers a specific level of aesthetic beauty for its intended use.

Sheet Preparation

Workers clean the metal pieces thoroughly. They also square and cut them to specifications. This pre-sizing creates a smooth, even surface. Proper preparation ensures a high-quality result. It allows for accurate perforation in both size and placement.

Perforation Process

Specialized machinery creates the perforations. It stamps or punches holes into the metal sheet. This step forms the intended pattern precisely. The machinery ensures consistent hole size and spacing. This defines the panel’s final functional and visual character.

Deburring and Finishing

The process removes sharp edges and burrs. This ensures safety and improves product quality. Workers then treat the metal sheet for enhanced durability. They may apply an anodized or powder coating. PVDF or polytop coatings are also common options. These finishes boost both appearance and performance.

Quality Control

Inspectors perform thorough checks on each panel. They verify measurements and hole spacing accurately. They also examine the surface finish carefully. This quality assurance minimizes defects. It ensures the product meets all industrial and project specifications.

Cutting and Forming

Manufacturers cut perforated sheets to specific designs. They shape them for architectural or industrial settings. Techniques include bending, welding, and framing. These methods produce custom features. The results serve diverse functional and aesthetic purposes.

Highlights of Perforated Metal Privacy Fence Panels

Perforated Metal Privacy Fence panels transform areas into beautiful works of art. They also serve highly functional purposes. They adapt easily to a wide variety of uses. Common applications improve privacy and air circulation in buildings.

Aesthetic Appeal

Intricate patterns and themes adorn these panels. They give interior and exterior spaces striking clarity. They also infuse a sophisticated, trendy character. This suits contemporary design perfectly.

Functionality

The fence panels manage light and color beautifully. They also regulate temperature flow naturally. This creates a comfortable environment. They provide proportional privacy with visibility. This builds amicable and productive spaces.

Customization

Manufacturers make panels in various materials and finishes. They also offer many pattern options. They adjust products to fulfill specific design requirements. Customization works on special architectural needs.

Durability

Builders construct panels with sturdy materials like stainless steel. Aluminum is another common choice. These materials withstand harsh conditions reliably. They maintain aesthetic values over time. Their timeless design ensures lasting attractiveness.

Easy Installation

The panels install easily on many projects. Their simple construction simplifies work for architects. This design guarantees straightforward installation. It also ensures long-term, trouble-free usage.

Sustainability

Many panels use recycled materials. They embody an eco-friendly philosophy. They promote the practice of green construction. This commitment benefits the environment. It also conserves valuable resources for a greener future.

These perforated metal privacy fence panels offer perfect solutions for global projects. They balance form, functionality, and serviceability effectively. They are customizable and sustainable, and help architectural solutions look excellent and last long.

Reviews

There are no reviews yet.