Description

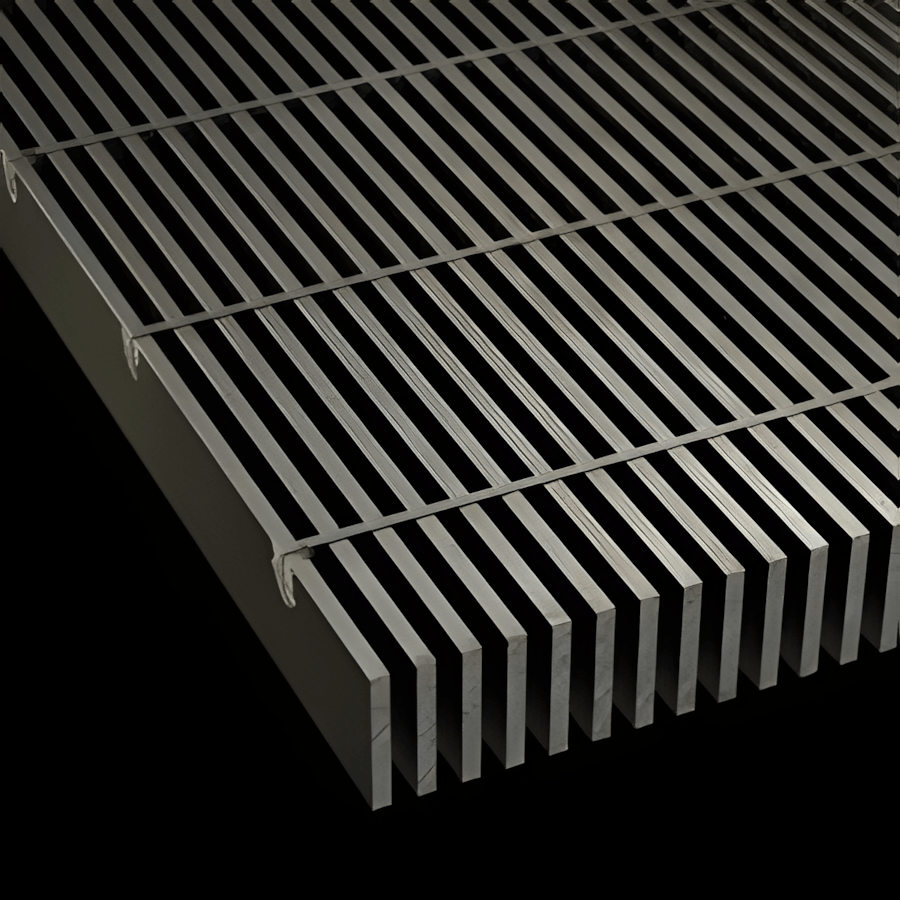

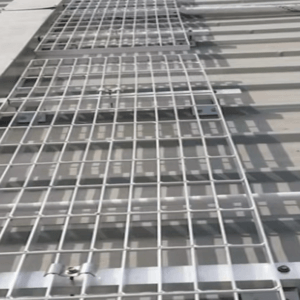

Press-Locked Grating is manufactured by inserting pre-punched bearing and cross bars into an interlocking configuration, then deforming the cross bars under intense hydraulic pressure. This method creates a smooth, rigid panel with exceptional load-bearing capacity and no visible welds. Available in galvanized carbon steel, stainless steel, and aluminum, it offers excellent corrosion resistance and a clean aesthetic. Ideal for architectural applications, pedestrian walkways, stair treads, and decorative screens, press-locked grating combines structural integrity with visual appeal, providing durable, low-maintenance solutions for both industrial and design-focused projects.

Classification of Press-Locked Grating

Materials: low carbon steel and stainless steel.

Surface treatment: galvanized, painted or powder coated.

Surface type: smooth surface and serrated surface

>Serrated surface type:

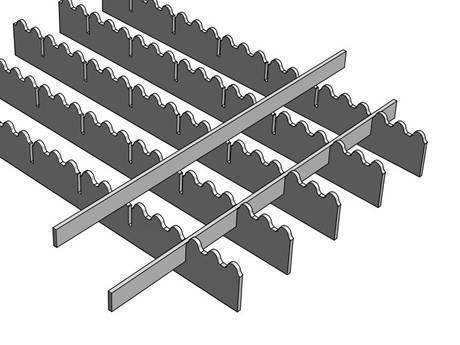

PR/S1: Trapezoidal teeth on the bearing bar.

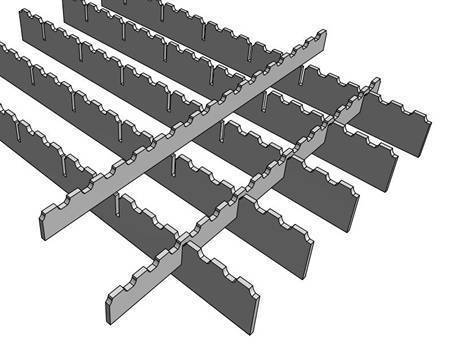

PR/S2: Trapezoidal tooth both on the bearing bar and cross bar with the highest non-slip performance. In this three types. it is most popular.

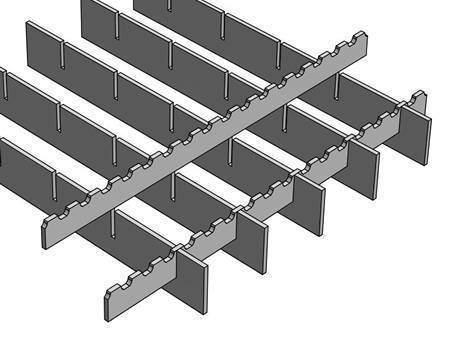

PR/S3: The non-slip tooth is applied to the connect components. It has the lowest non-slip performance.

|  |  |  |

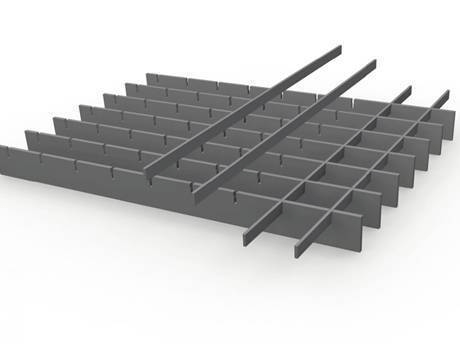

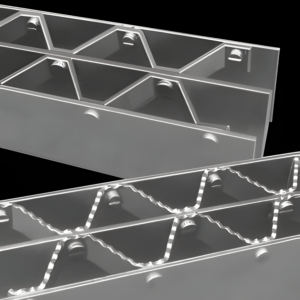

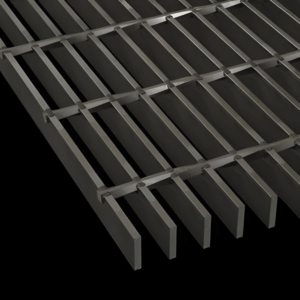

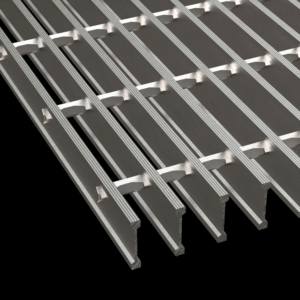

| A smooth surface press-locked steel grating. | PR-S1 surface. | PR-S2 surface. | PR-S3 surface. |

Types of press-locked steel grating by insertion angles and insertion modes:

|  |  |  |

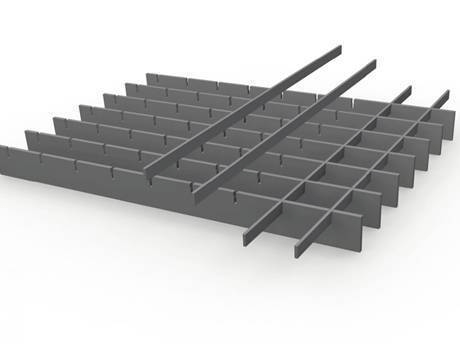

| Common steel grating. | Integral steel grating. | Heavy duty steel grating. | Louver steel grating. |

Common type:

- After the grooving of bearing bar, the cross bar press locked and molded.

- Maximum machining height of common steel grating is 100 mm, the length of steel grating is less than 2000 mm.

- The standard height of bearing bar: 20 mm to 170 mm.

- The standard thickness of bearing bar: 2 mm, 3 mm, 4 mm, 5 mm.

| Bearing Bar mm | Cross Bar mm | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 11.1 | 11.1 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 | |

| 15 | 11.1 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 | |

| 21 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 22.2 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 33.3 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 44.4 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 55.5 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 66.6 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 99.9 | 11.1 | 16.65 | 21.0 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| Bearing Bar mm | Cross Bar mm | ||||||

|---|---|---|---|---|---|---|---|

| 21 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 25 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 33.3 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 50 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 66.6 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

| 99.9 | 16.65 | 22.2 | 33.3 | 44.4 | 49.95 | 66.6 | 99.9 |

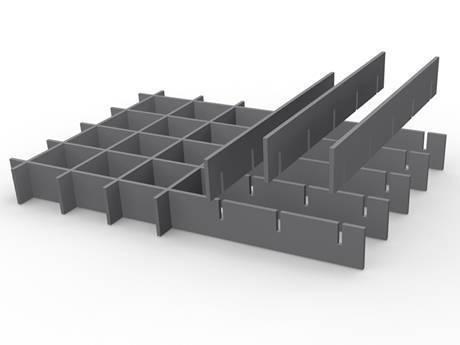

Integral type

- The bearing bar of integral steel grating has the same height as cross bar. The grooving depth is 1/2 of bearing bar.

- The height of the steel grating is less than 100 mm. and the length usually less than 2000 mm.

- The standard height of bearing bar: 20 mm to 100 mm.

- The standard thickness of bearing bar: 2 mm, 3 mm, 5 mm.

| Bearing Bar mm | Cross Bar mm | ||||

|---|---|---|---|---|---|

| 22.2 | 16.65 | 22.2 | 44.4 | 66.6 | |

| 33.3 | 16.65 | 22.2 | 33.3 | 66.6 | |

| 44.4 | 16.65 | 22.2 | 44.4 | ||

| 66.6 | 16.65 | 22.2 | 33.3 | 66.6 | |

| Bearing Bar mm | Cross Bar mm | |||

|---|---|---|---|---|

| 33.3 | 16.65 | 33.3 | 66.6 | 99.9 |

| 66.6 | 16.65 | 33.3 | 66.6 | |

| 99.9 | 16.65 | 33.3 | 99.9 | |

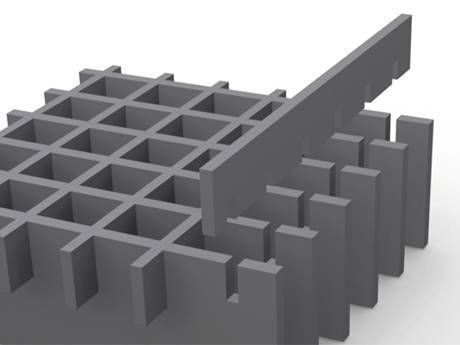

Heavy duty steel grating

- Heavy duty steel grating is bit by bearing bar and cross bar in the 1200 tons of pressure under the molding. It is suitable for high load bearing occasions.

- The standard height of bearing bar: 80 mm to 200 mm.

- The standard thickness of bearing bar: 8 mm, 10 mm, 12 mm.

| Bearing Bar mm | Cross Bar mm | ||

|---|---|---|---|

| 25 | 50 | 75 | 100 |

| 50 | 50 | 75 | 100 |

| 75 | 50 | 75 | 100 |

| 100 | 50 | 75 | 100 |

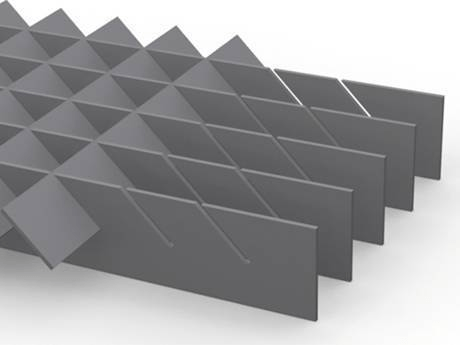

Louver steel grating

- The bearing bar of louver steel grating open the chute with 30° or 45°. The cross bar grooved and press locked.

- The grating height is less than 100 mm.

- The standard height of bearing bar: 30 mm to 100 mm.

- The standard thickness of bearing bar: 2 mm, 3 mm.

| Bearing Bar mm | Cross Bar mm | |||

|---|---|---|---|---|

| 33.3 | 16.65 | 22.2 | 33.3 | 66.6 |

| 66.6 | 16.65 | 22.2 | 33.3 | 66.6 |

| 99.9 | 16.65 | 22.2 | 33.3 | 66.6 |

Note: According to the different requirements. we can produce the steel grating with other specifications and spacing

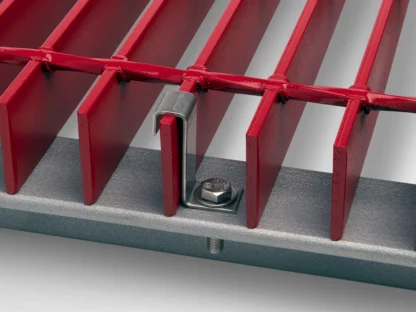

Steel Bar Grating Welding & Fastening Clips

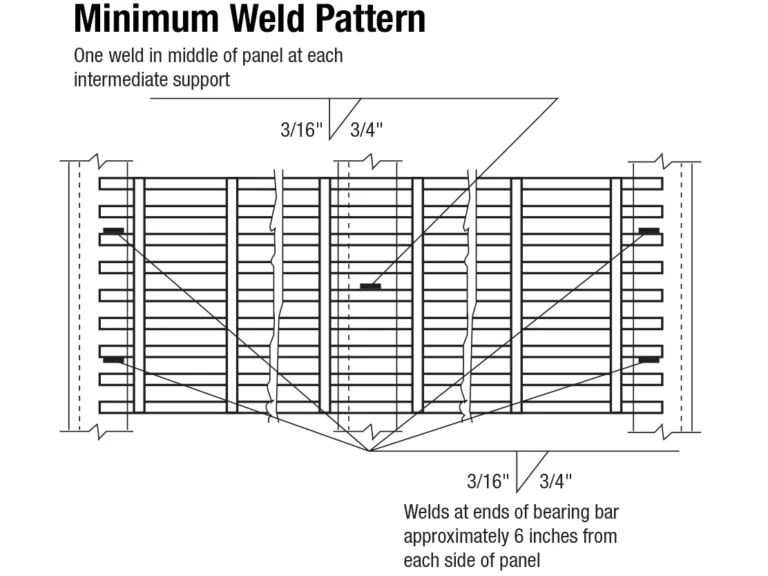

| Welding creates superior permanent installations, while mechanical fasteners (also known as grating clips) provide solutions when grating must be removable or welding is impractical. The recommended weld pattern (illustrated to the right) indicates minimum fastener spacing for pedestrian applications. Vehicular applications typically require additional welding, with specific size and spacing requirements determined by the project’s specifying authority. |  |

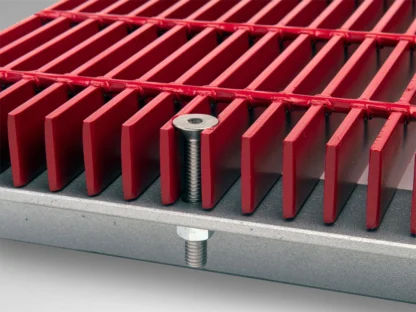

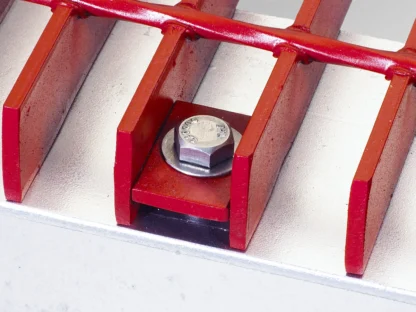

These bent clips, which bridge two bearing bars, are available in galvanized steel, stainless steel, or aluminum. They feature standard 5/16″ bolt holes. Bolts, screws, or other connecting hardware are not included and must be supplied separately. |  The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to accommodate bolt shoulders. Flat head screws or self-drilling fasteners are not included and must be supplied separately. |  Workers weld these pre-punched plates between the bearing bars to facilitate bolting to the supporting structure. Clients must supply bolts, screws, or other connecting hardware separately. |

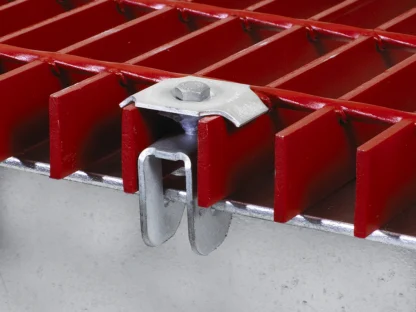

Installed from the top surface of the grating, these mechanical fasteners create a friction connection with the supporting flange. “G” clips are easily installed without the need for drilling or welding. |  This formed clip captures two bearing bars spaced at 11/16″ on center. Clients must supply flat countersunk screws and other required fastening hardware separately. |  A narrow formed clip used to capture a single bearing bar in applications with limited spacing, typically 11/16″ on center. Cap screws and other necessary fastening hardware are not included and must be supplied separately. |

Press-Locked Grating Applications

Grating Material Selection: Galvanized Steel VS Aluminium VS Stainless Steel

| Property | Stainless Steel | Aluminium | Galvanized Steel |

|---|---|---|---|

| Material Type | Austenitic (304, 316) or Ferritic grades | 6000 series (6061, 6063) or 5000 series | Low-carbon steel with zinc coating |

| Corrosion Resistance | Excellent, especially in chloride environments (316 grade) | Good, forms natural oxide layer | Good, depends on zinc coating thickness & environment |

| Strength | High tensile strength, maintains performance at high temperatures | Moderate strength, lower than steel | High strength, similar to base carbon steel |

| Weight | Heavy (~8 g/cm³) | Light (~2.7 g/cm³) | Heavy (~7.85 g/cm³) |

| Cost | High | Moderate | Low to moderate |

| Typical Applications | Chemical plants, food processing, marine platforms, high-corrosion areas | Walkways, platforms, marine structures, architectural features | Industrial flooring, trench covers, walkways, general outdoor use |

| Maintenance | Low, only periodic cleaning required | Low, resistant to oxidation | Moderate, may require recoating if zinc layer degrades |

| Workability | Difficult to cut/weld, requires specific tools & techniques | Easy to cut, form, and weld | Easy to work with standard steel tools |

| Surface Options | Mill finish, brushed, polished, patterned | Anodized, powder-coated, mill finish | Hot-dip galvanized, painted, powder-coated |

| Environmental Resistance | Resists UV, chemicals, saltwater | Resists atmospheric corrosion, not suitable for strong acids/alkalis | Good outdoor durability, zinc protects against rust |

| Life Expectancy | 25+ years (depending on grade and environment) | 15–25 years | 10–20 years (depending on coating and exposure) |

| Recyclability | Fully recyclable, high scrap value | 100% recyclable, energy-efficient to recycle | Recyclable, zinc coating can be recovered |

| Installation Notes | Heavy, may require stronger supports | Lightweight, easy to handle and install | Heavier than aluminium, standard steel handling required |

Note: Performance may vary based on specific grade, thickness, coating quality, and environmental conditions.

ABX Metal: Your Premier Full-Service Grating Partner

ABX Metal is your trusted, comprehensive grating manufacturer. Whether you require standard stock panels or fully custom fabrication, we meet every demand with precision and reliability. As your dedicated partner, we seamlessly guide your project from initial concept to delivery of fully fabricated, ready-to-install grating systems.

Our team delivers tailored solutions that align perfectly with your project’s specifications. The Sales, Engineering, Drafting, and Fabrication departments work in close collaboration with you to bring your vision to life. From preliminary structural layouts to detailed grating plans, we utilize advanced computer-aided design (CAD) and 3D modeling software to ensure accuracy, efficiency, and clarity throughout every phase.

As both manufacturer and fabricator, we offer integrated “One Source” solutions for all grating needs. Our culture of continuous improvement drives us to optimize processes, enhance quality, and maximize value at every stage.

Your complete satisfaction is our foremost commitment. We strive to deliver exceptional products and responsive service from project inception through completion.

Fabrication Capabilities Include:

Designing circular layouts and radial platforms

Precision cutting to specified dimensions

Creating custom cutouts for panel penetrations

Welding banding, kick plates, or safety nosings

Fabricating stair treads and specialized access systems

Incorporating custom features such as checker plate, lifting handles, and hinges

With ABX Metal, you gain a partner dedicated to quality, innovation, and seamless execution—ensuring your grating solutions are built to perform and designed to last.

Reviews

There are no reviews yet.