Description

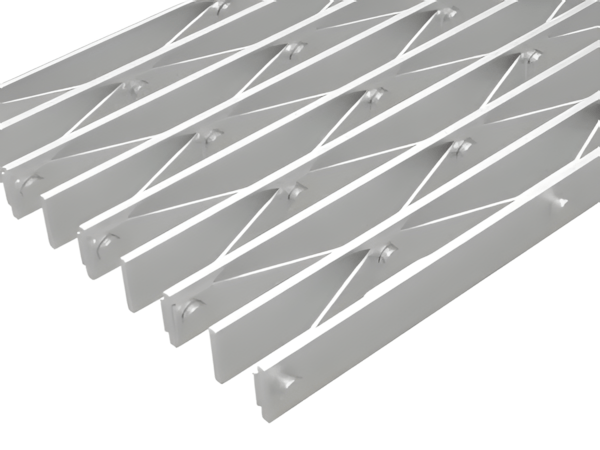

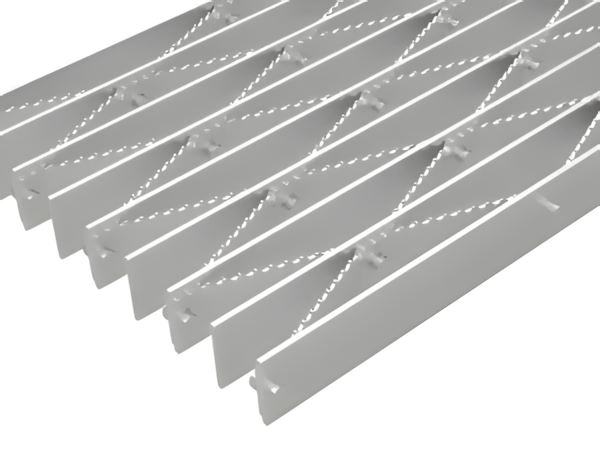

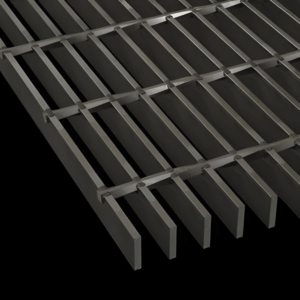

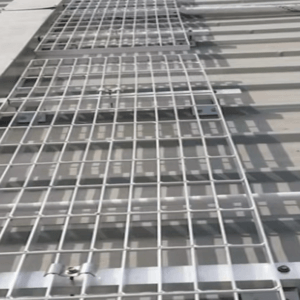

We manufacture Riveted Grating using a cold press process that joins straight bearing bars to crimped rectangular flats. As the oldest type of grating available, riveted products offer exceptional resistance to impact and fatigue while handling repetitive loads with superior performance.

Engineers select riveted gratings for high-strength applications that demand exceptional stiffness. Bridge decking commonly utilizes this heavy-duty grating solution.

Riveted Grating Details

Specifications

Material: Carbon steel, 6000 series aluminum, 300 series stainless steel

Category: Light duty and heavy duty classifications based on load capacity

Surface Treatment: Galvanized, painted, or mill finished

Surface Type: Smooth or serrated options available

|

|

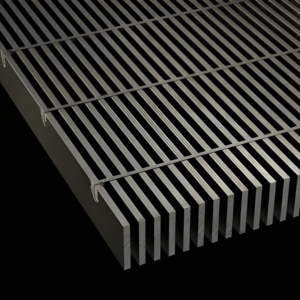

| Ideal for rolling stock and wheeled equipment operations, particularly with casters, as the reticulated bars provide smoother movement. Also excellent for walkways where enhanced walking comfort is desired. | Standard Serrated: Features serrated crimped cross members for superior slip resistance. 100% Serrated: Includes serration on both bearing bars and cross members for maximum walking security. |

Design

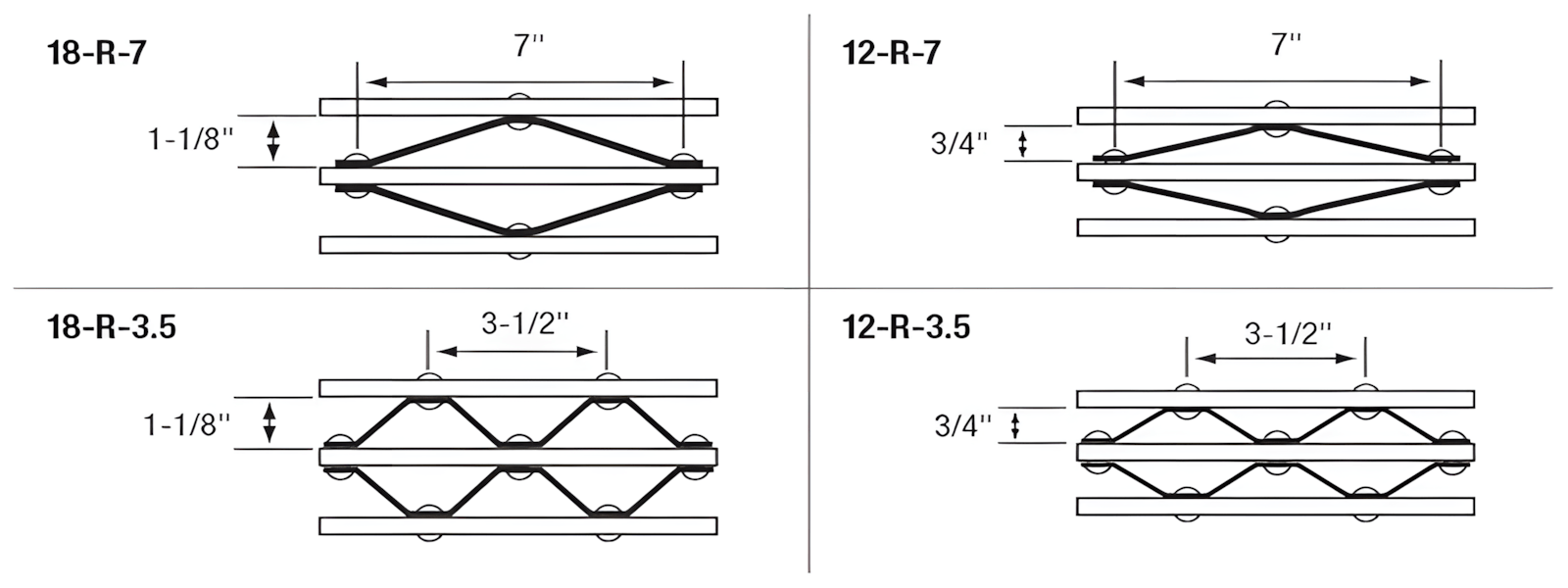

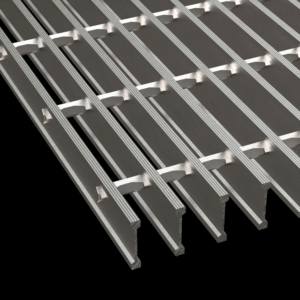

We offer three material choices: carbon steel, 6000 series aluminum, and 300 series stainless steel. Standard bearing bar spacing options include 1-1/8″ or 3/4″, with standard rivet spacing at 7 inches on center. Closer 3-1/2″ rivet spacing is available upon request.

Our standard design incorporates slightly raised serrated reticuline bars during assembly. Customers may specify 100% serration covering both bearing bars and cross members for enhanced safety.

Riveted Grating Spacing Options

The part numbering system uses “R” for carbon steel products. For aluminum products, substitute “AR” (e.g., Type 18-AR-7). For stainless steel, use “SR” (e.g., Type 12-SR-7). The numbering indicates bearing bar spacing and rivet spacing configuration.

Fabrication Capabilities

Engineering Services

ABX provides comprehensive engineering support from concept through production, including design consultation, technical manuals, field technical representatives, CAD drafting, engineering certification, and custom design services.

Custom Fabrication

Our trained technicians transform stock panels into custom components according to your exact specifications. Services include precision layout and cutting, stair tread and frame fabrication, lifting device installation, and complete finishing processes. In-house fabrication reduces field labor costs and eliminates onsite scrap disposal.

All fabricated materials receive proper finishing to ensure maximum product lifespan. We piece-mark panels to correspond with installation drawings, which accompany every shipment. Our accurate and prompt fabrication services ensure straightforward installation.

Fabrication Services Include:

Sawing and flame cutting

Plasma cutting and welding

Punching and banding

Comprehensive finishing services

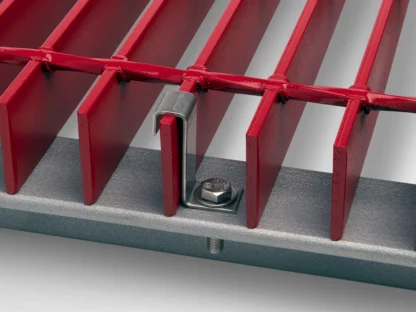

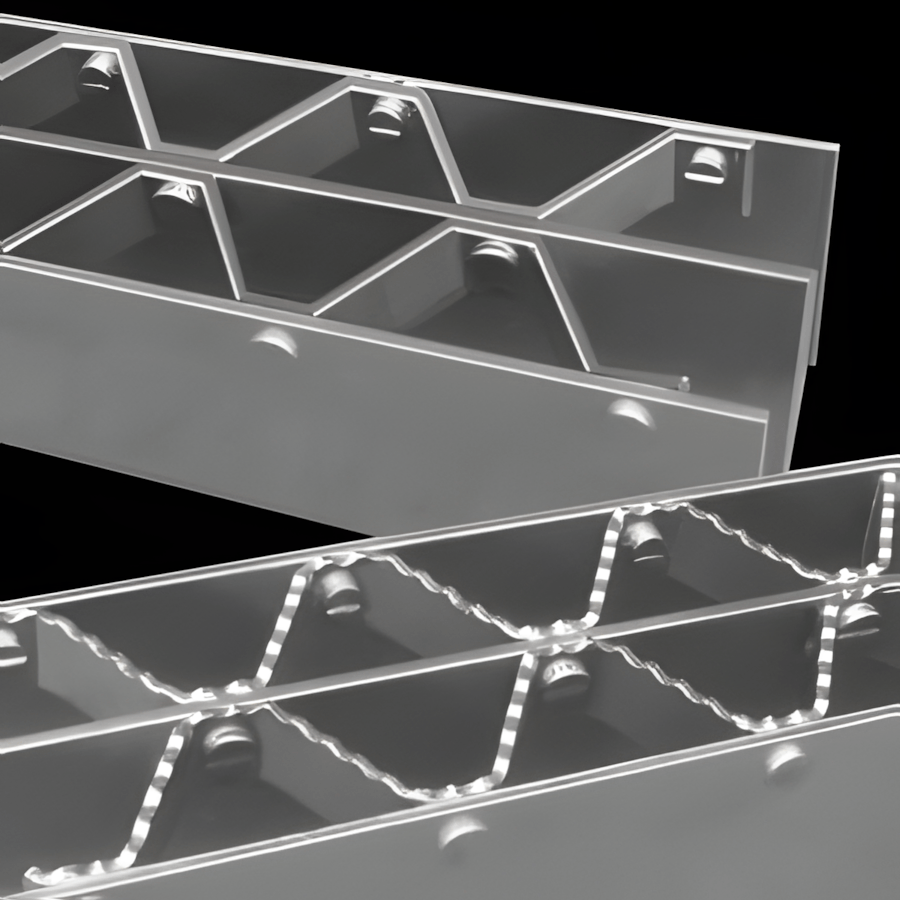

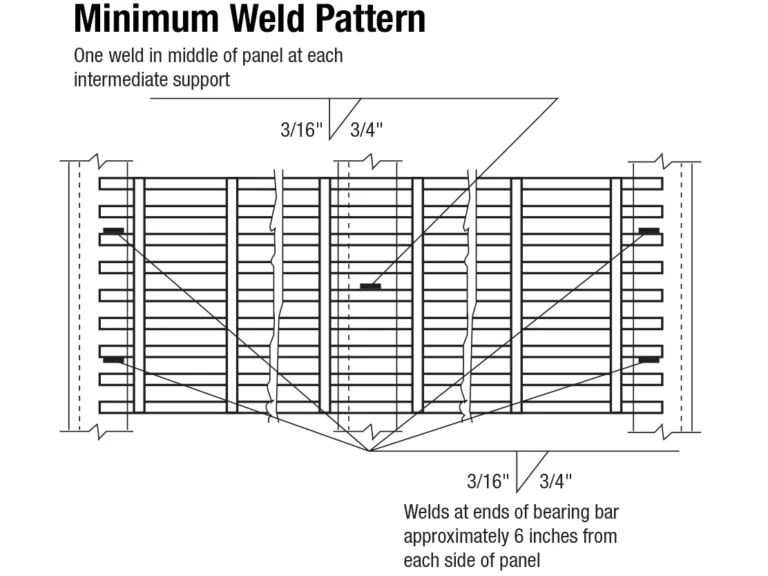

Steel Bar Grating Welding & Fastening Clips

| Welding creates superior permanent installations, while mechanical fasteners (also known as grating clips) provide solutions when grating must be removable or welding is impractical. The recommended weld pattern (illustrated to the right) indicates minimum fastener spacing for pedestrian applications. Vehicular applications typically require additional welding, with specific size and spacing requirements determined by the project’s specifying authority. |

|

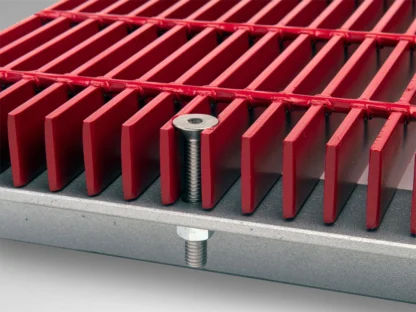

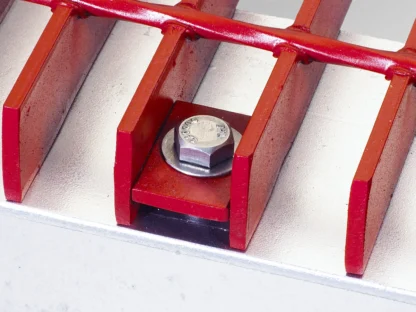

These bent clips, which bridge two bearing bars, are available in galvanized steel, stainless steel, or aluminum. They feature standard 5/16″ bolt holes. Bolts, screws, or other connecting hardware are not included and must be supplied separately. |  The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to accommodate bolt shoulders. Flat head screws or self-drilling fasteners are not included and must be supplied separately. |  Workers weld these pre-punched plates between the bearing bars to facilitate bolting to the supporting structure. Clients must supply bolts, screws, or other connecting hardware separately. |

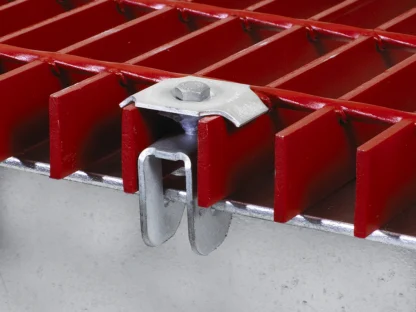

Installed from the top surface of the grating, these mechanical fasteners create a friction connection with the supporting flange. “G” clips are easily installed without the need for drilling or welding. |  This formed clip captures two bearing bars spaced at 11/16″ on center. Clients must supply flat countersunk screws and other required fastening hardware separately. |  A narrow formed clip used to capture a single bearing bar in applications with limited spacing, typically 11/16″ on center. Cap screws and other necessary fastening hardware are not included and must be supplied separately. |

Reviews

There are no reviews yet.